World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DSPAF1ABH - Software PROM is available in stock which ships the same day.

DS200DSPAF1ABH - Software PROM comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DSPAF1ABH - Software PROM, contact us and we will get back to you within 24 hours.

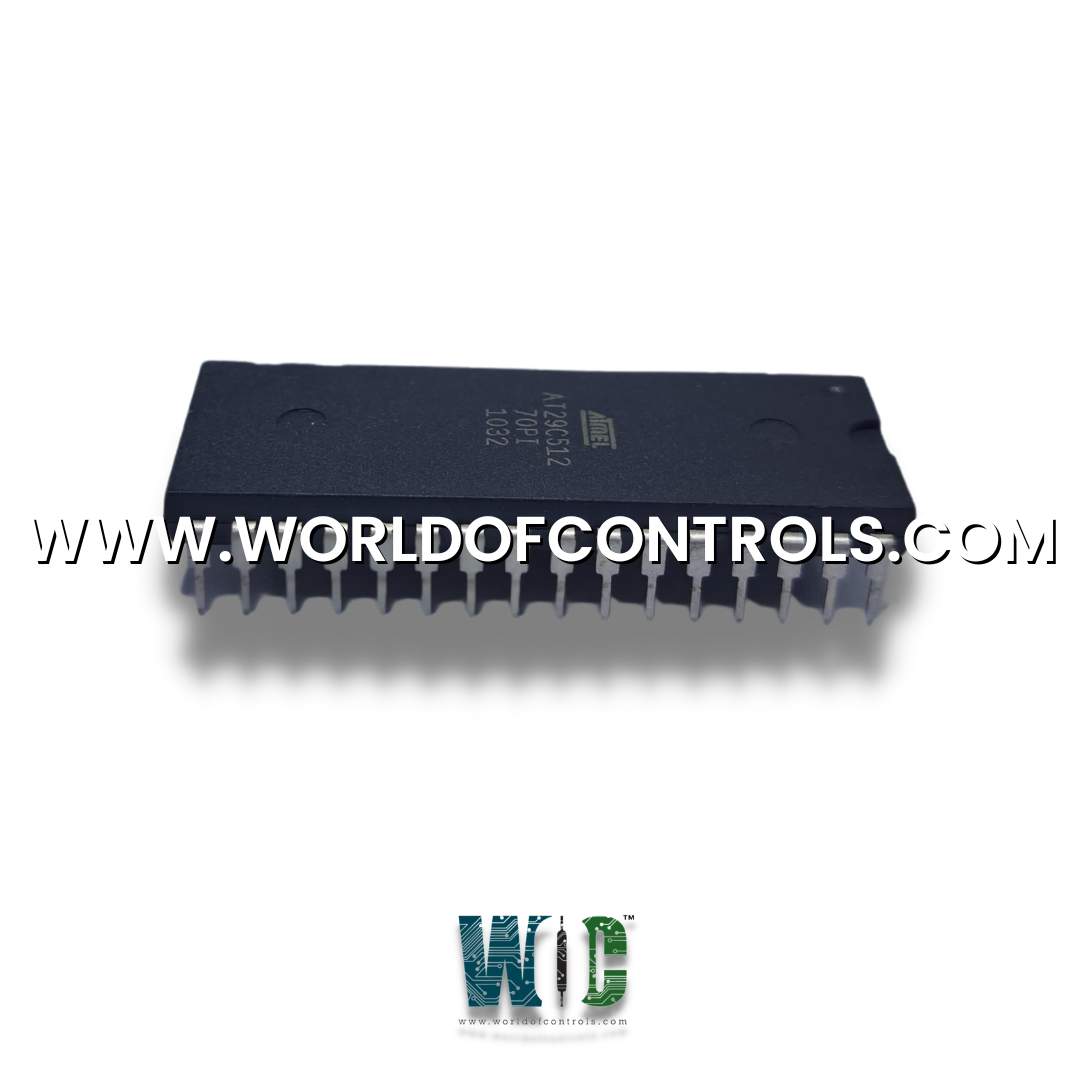

Part Number: DS200DSPAF1ABH

Manufacturer: General Electric

Series: Mark V

Product type: Software PROM

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DSPAF1ABH is a Software PROM designed and developed by GE. It is a part of the Mark V control system. The Mark V is a cutting-edge, fully programmable turbine control system meticulously crafted to cater to the intricate and ever-evolving demands of the contemporary power generation industry. Specifically engineered to handle the dynamic behaviors exhibited by gas and steam turbines, this system exemplifies flexibility and sophistication, offering a comprehensive suite of control, monitoring, and protective functionalities that are at the forefront of technology.

At its core, the Mark V leverages General Electric's rich expertise in turbine control applications and combines it with state-of-the-art electronic hardware and software. This synergy empowers operators with immediate access to an extensive array of critical control functions, along with the capability to perform in-depth monitoring. Furthermore, the system boasts a host of built-in features that act as a vigilant safeguard, automatically shielding the turbine generator from various abnormal operating conditions. These include but are not limited to, scenarios such as overspeed, oil loss, and overheating.

The Mark V distinguishes itself with an impressive array of features, underscoring its capabilities:

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

What is DS200DSPAF1ABH?

It is a Software PROM designed and developed by GE

What is the significance of the triple modular redundant (TMR) architecture?

The TMR architecture offers a high level of redundancy, tripling the reliability of the system by ensuring it can continue operating even in the presence of component failures.

How does online maintenance benefit operators?

Online maintenance enables operators to perform maintenance tasks while the system is running, minimizing downtime and maximizing system efficiency.

What is the role of the direct sensor interface in the control system?

The direct sensor interface allows the system to directly acquire real-time data from sensors, providing precise insights into the performance and health of the turbine.

How do built-in diagnostics work in the Mark V?

The Mark V is equipped with a sophisticated diagnostics system that continuously monitors the system's health, promptly detecting and reporting anomalies or issues, facilitating proactive maintenance and issue resolution.