World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DSPAF1ABF - Software PROM Set is available in stock which ships the same day.

DS200DSPAF1ABF - Software PROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DSPAF1ABF - Software PROM Set, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

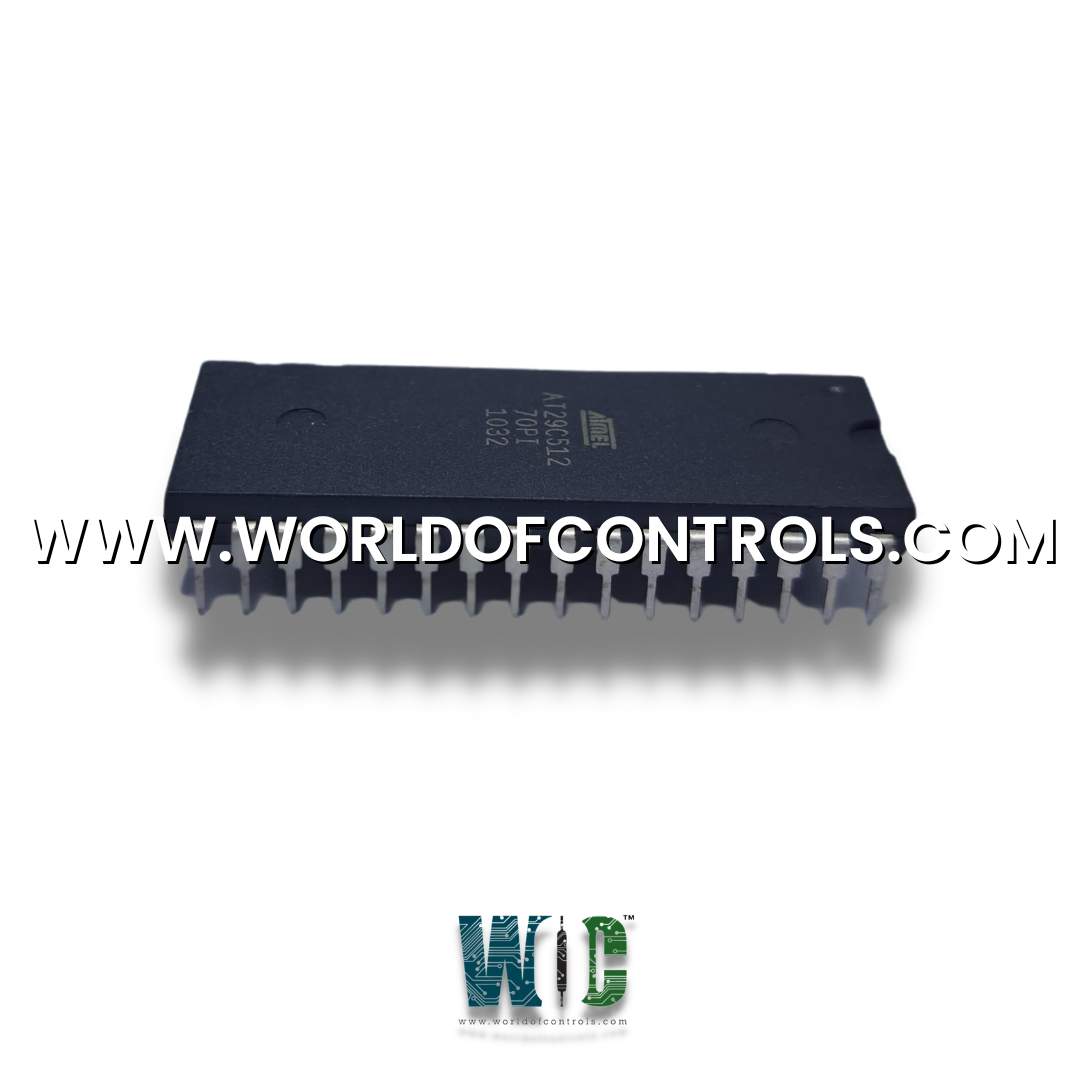

Part Number: DS200DSPAF1ABF

Manufacturer: General Electric

Series: Mark V

Product Type: Software PROM Set

Operating temperature: -30 to 55 °C

Size: 8.25 cm high x 4.18 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200DSPAF1ABF is a Software PROM Set manufactured and designed by General Electric as part of the Mark V Series used in GE Speedtronic Gas Turbine Control Systems. A programmable read-only memory (PROM) is a type of digital memory that can be programmed once after the device is manufactured. Once written, the data is permanent and cannot be changed. PROM is a subset of read-only memory (ROM). It is typically used in digital electronic devices to store permanent data, such as firmware or microcode. The main difference between PROM and standard ROM is that ROM data is written during the manufacturing process, whereas PROM data is programmed after manufacturing. Consequently, ROMs are generally used for large production runs with verified data, while PROMs are suitable for smaller quantities where factory-programmed ROMs are not cost-effective, or during the development phase of a system that may later transition to mass-produced ROMs.

OPERATION:

A programmable read-only memory (PROM) is a type of digital memory that can be programmed once after the device is manufactured. Once written, the data becomes permanent and cannot be altered. PROMs are used to store permanent data in digital electronic devices, such as firmware or microcode. Unlike standard read-only memory (ROM), where data is written during the manufacturing process, PROM data is programmed post-manufacture. This makes ROMs ideal for large production runs with well-verified data. In contrast, PROMs are used for smaller production volumes where factory-programmed ROMs are not economical or during system development, which may later be converted to ROMs for mass production.

APPLICATIONS:

WOC offers the largest inventory of GE Speedtronic Control System replacement parts, including both new and refurbished items, all backed by a warranty. Our team of experts is available 24/7 to support your OEM needs and assist with any automation requirements. For pricing and availability of parts and repairs, please contact our team by phone or email.

How is PROM different from ROM?

The key difference is that data in ROM is written during the manufacturing process, whereas in PROM, the data is programmed after manufacturing. ROM is used for large production runs with fixed data, while PROM is used for smaller quantities or during development.

What are common uses for PROM?

PROMs are commonly used to store firmware, microcode, and configuration data in electronic devices. They are also used during the prototyping and development stages of systems before mass production.

What are the advantages of using PROM?

PROM offers flexibility in programming data after manufacture, making it suitable for customized applications and reducing the risk of errors during the development stage.