World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DMCBF1CFA - GE Software PROM Set is available in stock which ships the same day.

DS200DMCBF1CFA - GE Software PROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DMCBF1CFA - GE Software PROM Set, contact us and we will get back to you within 24 hours.

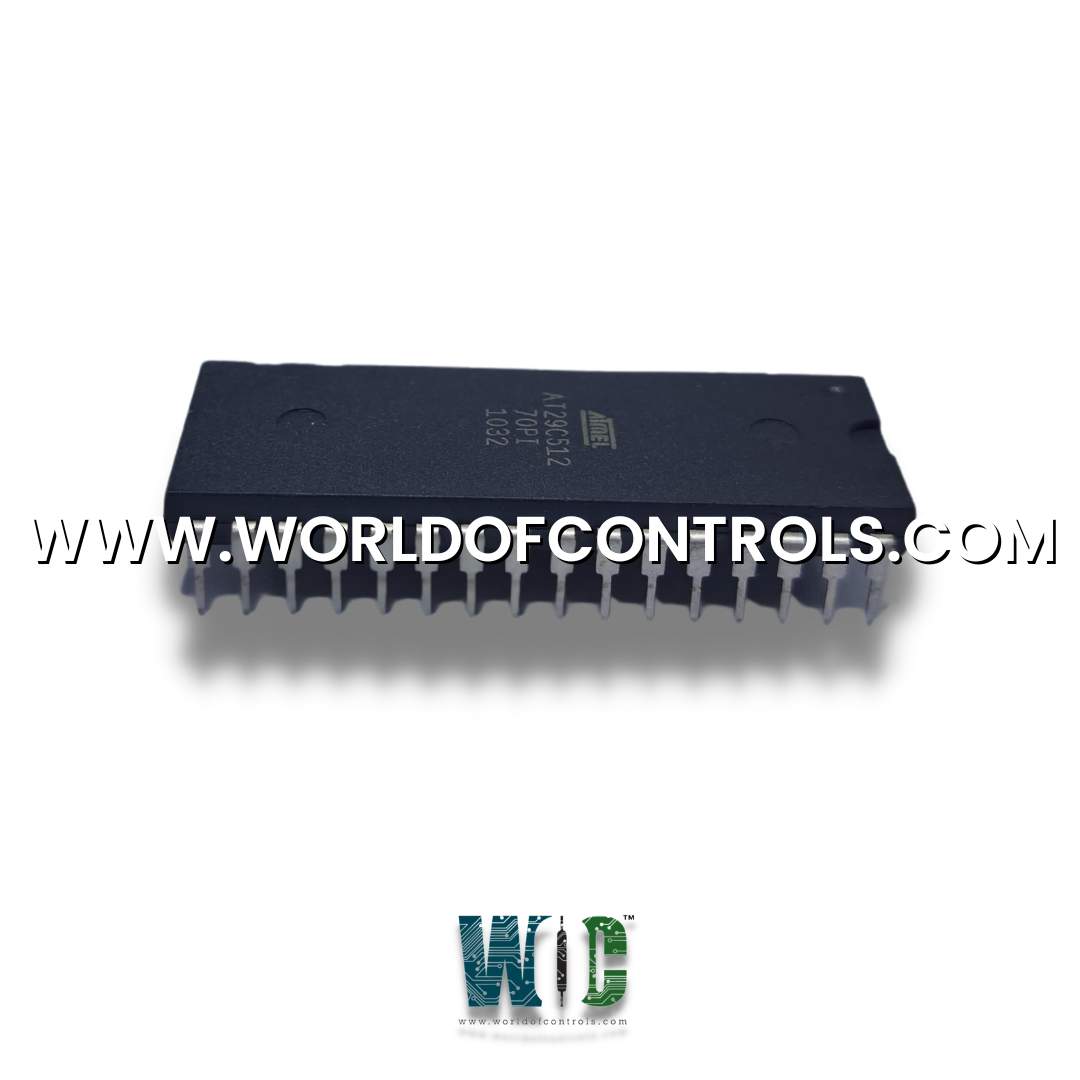

Part Number: DS200DMCBF1CFA

Manufacturer: General Electric

Series: Mark V

Product type: GE Software PROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DMCBF1CFA is a GE Software PROM Set designed and developed by GE. It is a part of the Mark V control system.�Mark V systems incorporate redundancy features, such as multiple controllers and power supplies, to enhance system reliability and availability. The system often includes communication interfaces that allow it to connect with other control and monitoring systems. This communication capability enables data sharing and remote monitoring.

WOC is available 24x7 to assist you with any of your General Electric requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

What is DS200DMCBF1CFA?

It is a GE Software PROM Set designed and developed by GE

What kind of data do these controllers acquire, and how does it impact turbine performance?

The controllers acquire essential data from various sensors and generate outputs that directly affect the performance of the steam turbine.

How is overspeed protection and other protective functions managed in this system?

Protective functions, including overspeed protection, are channeled through the P module, which comprises triple redundant processors (X, Y, and Z). These processors operate independently to provide an additional layer of protection.

Are all sensors used in this system triple-redundant?

Critical sensors for continuous control and protection are triple-redundant to ensure high reliability. However, other sensors may be dual or single devices, with data distributed to all three control processors to maintain redundancy.

What is the key factor contributing to the remarkable reliability of the TMR control system?

The use of triple sensors for all critical parameters is a fundamental principle that enhances the reliability and safety of the system.