SPECIFICATIONS

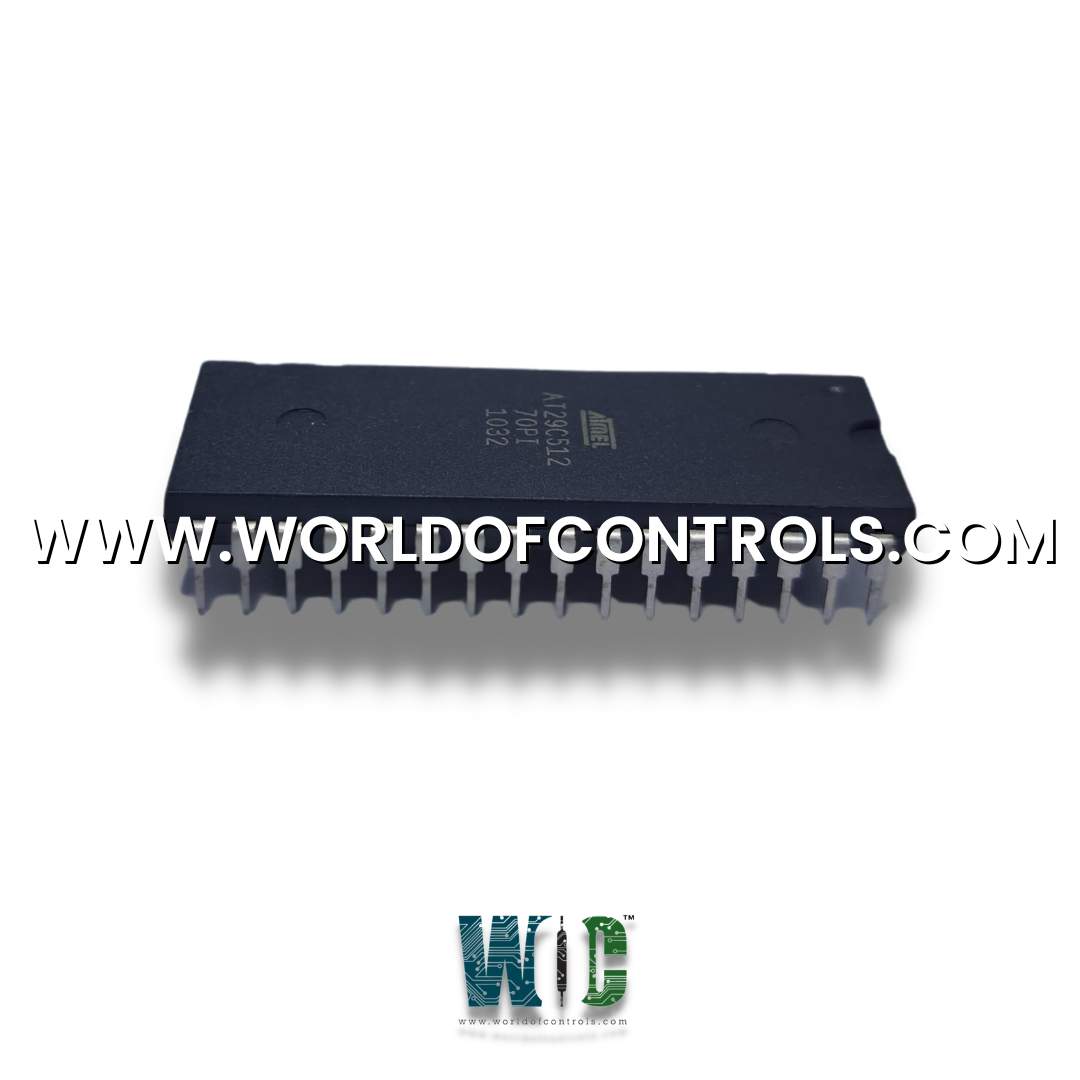

Part Number: DS200DENQF1BDE

Manufacturer: General Electric

Series: Mark V

Product type: Software EPROM

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

DS200DENQF1BDE is a software EPROM designed and developed by GE. It is a part of the Mark V control system. The Mark V system collects and processes real-time data from sensors and instruments to provide operators with a clear overview of the turbine's performance. This data is crucial for maintaining and optimizing the system. It employs advanced control algorithms and logic to make real-time decisions for controlling the turbine, ensuring efficient operation under various load and environmental conditions.

System Overspeed Features

- The system utilizes a protective controller with three distinct cards denoted X, Y, and Z, each equipped with their individual processors and power supplies. This arrangement offers a high degree of redundancy in terms of electronics, forming a triple-redundant system. Alongside these cards are three separate speed pickups, forming an integral part of the system that effectively replaces the traditional mechanical overspeed governor.

- Within this setup, components R, S, and T make use of the first set of three pickups for managing speed control and serving as the primary means of overspeed protection. Meanwhile, X, Y, and Z are tasked with monitoring a secondary set of three-speed pickups, which are reserved for emergency overspeed protection, ensuring that the system can swiftly respond to critical situations.

- Furthermore, each of the X, Y, and Z cards incorporates separate relay drivers and magnetic relays. These components play a crucial role by conducting a final contact vote before initiating the turbine trip solenoids. In the event of any anomalies or failures, diagnostics are in place to constantly assess the state of the output ports, relay drivers, and relays. Should a malfunction occur, these diagnostics can trigger maintenance alarms, thereby facilitating timely attention to the issue.

- To maintain the reliability and effectiveness of the system, there are built-in features for both online and offline primary and emergency overspeed trip tests. These tests serve the purpose of verifying the proper functioning of both hardware and software components. The setup ensures that the system is well-equipped to handle overspeed scenarios while maintaining high standards of safety and performance.

Product Attributes

- EPROM boasts an array of cutting-edge features, including built-in diagnostics, online maintenance accessibility, direct sensor interface capabilities, and a TMR (triple modular redundant) architecture. The versatility of its architecture allows it to be configured as Simplex, particularly suitable for less complex systems.

- EPROMs, as erasable programmable read-only memory chips, retain data even when power is turned off. These chips, housed within boards like the SLCC LAN Communication card, specifically store LAN control processor software at U6 and U7. They are not configurable in the field, yet they are replaceable and transferrable between boards.

- It serve as crucial components within systems, acting as repositories for essential software and retaining programmed information, ensuring the system's integrity and functionality. These EPROMs hold vital LAN control processor software, enabling smooth and efficient operation of the SLCC LAN Communication card.

- The replaceability of these EPROM devices offers flexibility in maintenance and system upgrades. They can be interchanged between boards, facilitating system modifications or repairs without requiring complex reconfigurations, enhancing overall system maintenance efficiency.

WOC is available 24x7 to assist you with any of your General Electric Mark V requirements. Please contact us by phone or email for pricing and availability on GE, Bently Nevada or Woodward parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is DS200DENQF1BDE?

It is a Software EPROM designed and developed by GE

What is the significance of having three cards in the protective controller?

The three cards offer redundancy in the system, creating a triple-redundant setup for enhanced reliability.

How does the system handle overspeed protection?

The system uses three separate speed pickups, with components R, S, and T using the first set of three pickups for managing speed control and serving as the primary means of overspeed protection. Meanwhile, X, Y, and Z monitor a secondary set of three speed pickups reserved for emergency overspeed protection.

What role do relay drivers and magnetic relays play in the system?

Each of the X, Y, and Z cards incorporates separate relay drivers and magnetic relays. These components perform a final contact vote before initiating the turbine trip solenoids, ensuring the safety of the system.

How does the system handle anomalies or failures?

The system has built-in diagnostics to constantly assess the state of the output ports, relay drivers, and relays. If a malfunction occurs, these diagnostics can trigger maintenance alarms, ensuring prompt attention to the issue.