World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200DENQF1ACG - EPROM Set is available in stock which ships the same day.

DS200DENQF1ACG - EPROM Set comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200DENQF1ACG - EPROM Set, contact us and we will get back to you within 24 hours.

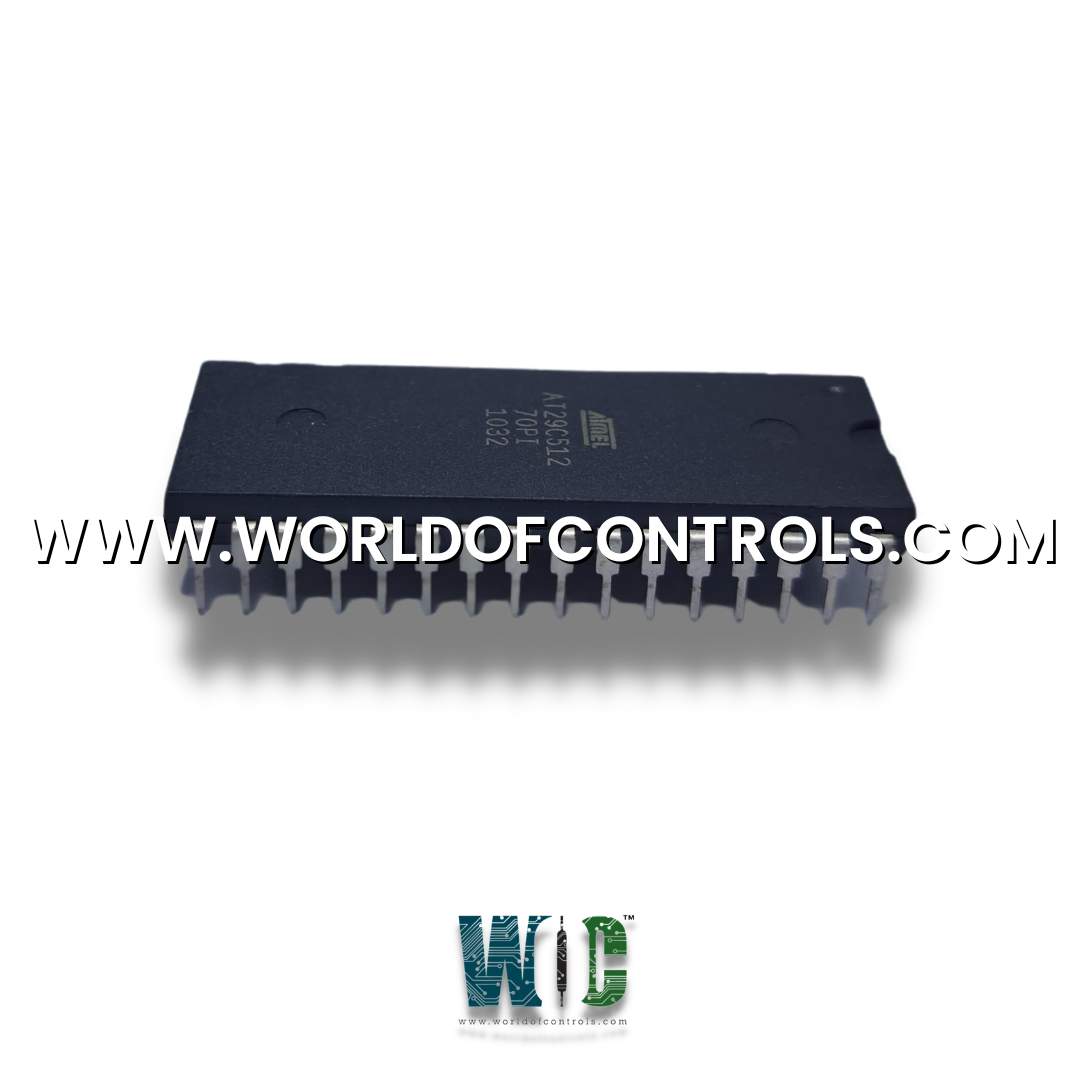

Part Number: DS200DENQF1ACG

Manufacturer: General Electric

Series: Mark V

Product type: EPROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

DS200DENQF1ACG is an EPROM set designed and developed by GE. It is a part of Mark V control system. Mark V system exhibits remarkable versatility by enabling a single historian to manage historical trending for as many as eight smaller units of various types, including generator excitation systems. This capacity streamlines the monitoring and analysis of multiple turbine units, enhancing the overall efficiency and performance of power generation systems.

The Mark V control system offers a comprehensive and efficient direct sensor interface, simplifying the integration and monitoring of various critical turbine and generator devices. Mark V control system's direct sensor interface is a robust and efficient solution for the seamless integration and monitoring of critical sensors in turbine and generator systems. It simplifies the control setup, minimizes reliability concerns, and ensures that critical data is readily available for operators while maintaining rigorous power supply redundancy and monitoring. This integrated approach contributes to the system's reliability and efficiency.

The Mark V I/O (Input/Output) system is purposefully designed for direct interfacing with an array of crucial devices associated with turbines and generators. These devices include thermocouples, Resistance Temperature Detectors (RTDs), and vibration sensors. This direct interface eliminates the need for additional interposing transducers and instrumentation, which not only streamlines the system but also eliminates associated costs and potential reliability issues.

One of the key benefits of the direct sensor interface is that it provides real-time monitoring of these sensors. The system offers direct access to data from these sensors through the Mark V control interface. Additionally, this data can be seamlessly transmitted to the Distributed Control System (DCS) via the communication link. This ensures that critical data is readily available to operators for immediate decision-making and is also accessible at the DCS level for comprehensive system oversight.

In a typical Mark V steam turbine control setup, the system is engineered for specific sensor integration. For example, it provides a direct interface to Proximitors for vibration protection and axial position information for thrust wear. It also incorporates differential expansion and eccentricity monitoring through a reference probe and key phasor. Furthermore, the system is equipped to monitor shell expansion through a Linear Variable Differential Transformer (LVDT) input. These integrations cater to the unique needs and sensitivities of steam turbine controls.

In terms of power supply, Mark V steam turbine controls come with standard redundant 115/230 V AC inputs and a 125 V DC input. The electronic components are powered by the highest bus voltage, and built-in diagnostics continuously monitor the actual voltage levels on each bus. The system also checks for any possible grounding issues on the 125 V DC bus, if it is utilized.

An internal power distribution module with fuses isolates the 125 V DC supply and feeds it to individual power supplies located in each controller. These internal feeders are closely monitored by diagnostics, ensuring stable and reliable power distribution. LED indicators located next to each fuse provide additional assistance for maintenance, aiding in quick identification of any issues.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is DS200DENQF1ACG?

It is a Mark V EPROM Set designed and developed by GE

What is the significance of the RS232 link with Modbus protocol in the Mark V system?

The RS232 link with the Modbus protocol is a widely used standard in industrial automation. It ensures compatibility with most Distributed Control Systems (DCSs) and facilitates seamless data exchange and control between different system components.

How does the Mark V system handle communication via Arcnet and Ethernet?

The Mark V system supports both Arcnet and Ethernet communication methods, offering flexibility and compatibility with various networking requirements. These options facilitate effective data transfer and system coordination.

What is GE's Message Service Protocol (TCP-IP) used for in the Mark V system?

GE's Message Service Protocol, based on TCP-IP, plays a vital role in communication. It is employed across various communication links, including RS232 and Ethernet, to relay time-tagged information related to alarms and events and synchronize the system with the Distributed Control System (DCS).

How does the Mark V system enable one-to-many communication, and why is this beneficial?

The system's design allows a single processor to communicate with one or multiple units. This feature simplifies the management of multiple turbine units, making it particularly advantageous in scenarios where several units need to be controlled and monitored simultaneously.