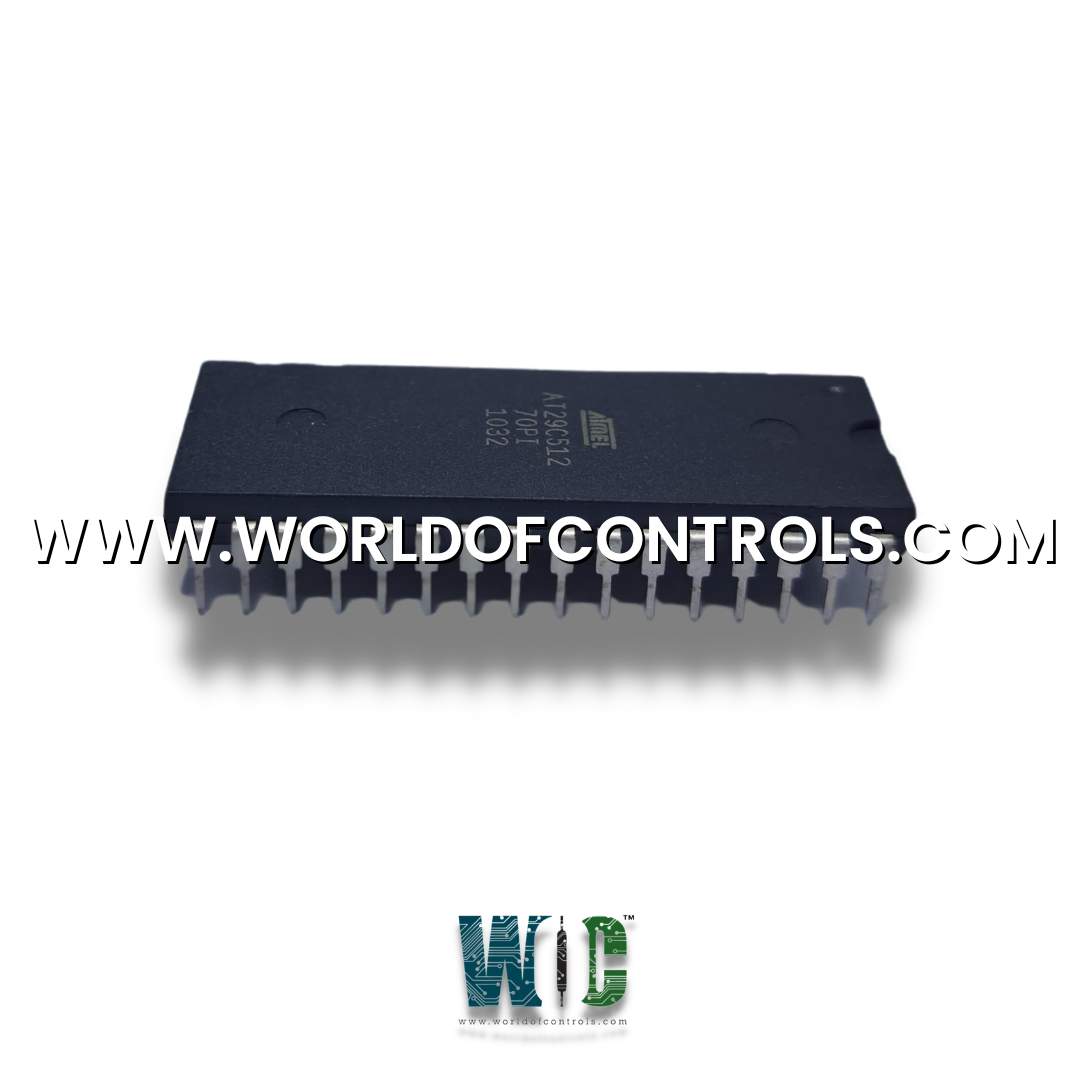

SPECIFICATIONS

Part Number: DS200DENCF1BDB

Manufacturer: General Electric

Series: Mark V

Product type: Software EPROM Set

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

DS200DENCF1BDB is a Software EPROM Set designed and developed by GE. It is a part of Mark V control system. As a result, the Mark V control system achieves significantly heightened levels of reliability, a faster mean-time-to-repair, and notably improved control system availability compared to the preceding SPEEDTRONICTM Mark IV applications. These advancements collectively mark a substantial leap forward in control system technology. The latest design enhancements encompass several critical areas, including microprocessor performance, I/O capacity, the integration of SIFT technology, diagnostic capabilities, standardization, and operator information. These improvements are coupled with a sustained commitment to application flexibility and meticulous design for ease of maintenance.

Mark V Data Communication Network

The Mark V Control System relies on a structured network infrastructure to ensure efficient communication and data exchange. There are three distinct data communication networks within the system, each serving a specific purpose and facilitating seamless interactions.

Stage Link

- The Stage Link network is the primary external communication network in the Mark V Control System.

- This network plays a pivotal role in connecting the Operator Interface, denoted as , with the common data processor, referred to as , located within the control panel.

- The Stage Link network employs an ARCNET configuration, which is known for its reliability and efficiency in data transmission.

- It serves as the main conduit through which data and commands are transmitted between the operator interface and the central data processor, ensuring real-time interaction and control.

Data Exchange Network (DENET)

- The Data Exchange Network, or DENET, is an internal communication network exclusive to the Mark V control panel.

- This network is structured as an ARCNET type communication system, optimized for secure and efficient internal data exchange.

- The primary function of DENET is to establish a communication link between the various internal processors housed within the control panel.

- In a Triple Modular Redundant (TMR) control panel configuration, DENET serves as the cornerstone for the voting process, a critical aspect of control signal interpretation.

- Through DENET, the internal processors can collaboratively evaluate and decide on control signals, ensuring accuracy and redundancy in the control system.

- These data communication networks within the Mark V Control System enable the seamless flow of information, facilitating effective monitoring and control of the system's components. The Stage Link network establishes a vital connection between the operator interface and the central data processor, while the DENET network serves as the internal communication backbone for the control panel, particularly in TMR configurations, ensuring the reliability and accuracy of control signals.

Features

- Within the Mark V Control System, the third internal network assumes the role of the I/O network (IONET). The IONET is structured as a serial communications network, and it is configured in a daisy chain topology, ensuring efficient and reliable data exchange. This network's primary purpose is to facilitate the seamless communication of input and output (I/O) signals between various key components, including the control processor (DCC), the protection core (P), and the digital I/O core (QD1).

- In the Mark V Control System, the IONET is implemented consistently across all processors, except for the control processor C. The C core differs in its connections since it lacks a direct link to the protection core (P). As a result, the IONET is primarily responsible for transmitting data between the C core and the digital I/O board. This configuration ensures that the I/O signals are accurately and efficiently relayed between these vital components, contributing to the seamless functioning of the control system.

- The number of IONETs varies depending on the control panel configuration. In a Triple Modular Redundant (TMR) panel, there are four independent IONETs, each corresponding to the control processors R, S, T, and C. On the other hand, in a Simplex panel, there are two IONETs, linked to the R and C processors.

- This carefully designed IONET architecture is instrumental in facilitating robust data communication and signal exchange within the Mark V Control System, ensuring that critical I/O signals are reliably conveyed between the control processors, protection core, and digital I/O core to support the system's operations effectively.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is DS200DENCF1BDB?

It is a Software EPROM Set designed and developed by GE

What is the primary function of the Data Exchange Network (DENET) within the Mark V Control System?

The DENET is an internal communication network that establishes links between internal processors. In a Triple Modular Redundant (TMR) panel, DENET serves as the foundation for the voting process, ensuring accuracy and redundancy in control signal interpretation.

What is the role of the I/O network (IONET) in the Mark V Control System?

The IONET is a serial communications network that facilitates the seamless communication of input and output (IO) signals between key components, such as the control processor (DCC), protection core (P), and digital IO core (QD1).

How many IONETs are there in a TMR control panel configuration?

In a Triple Modular Redundant (TMR) panel, there are four independent IONETs, each corresponding to the control processors R, S, T, and C.