World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

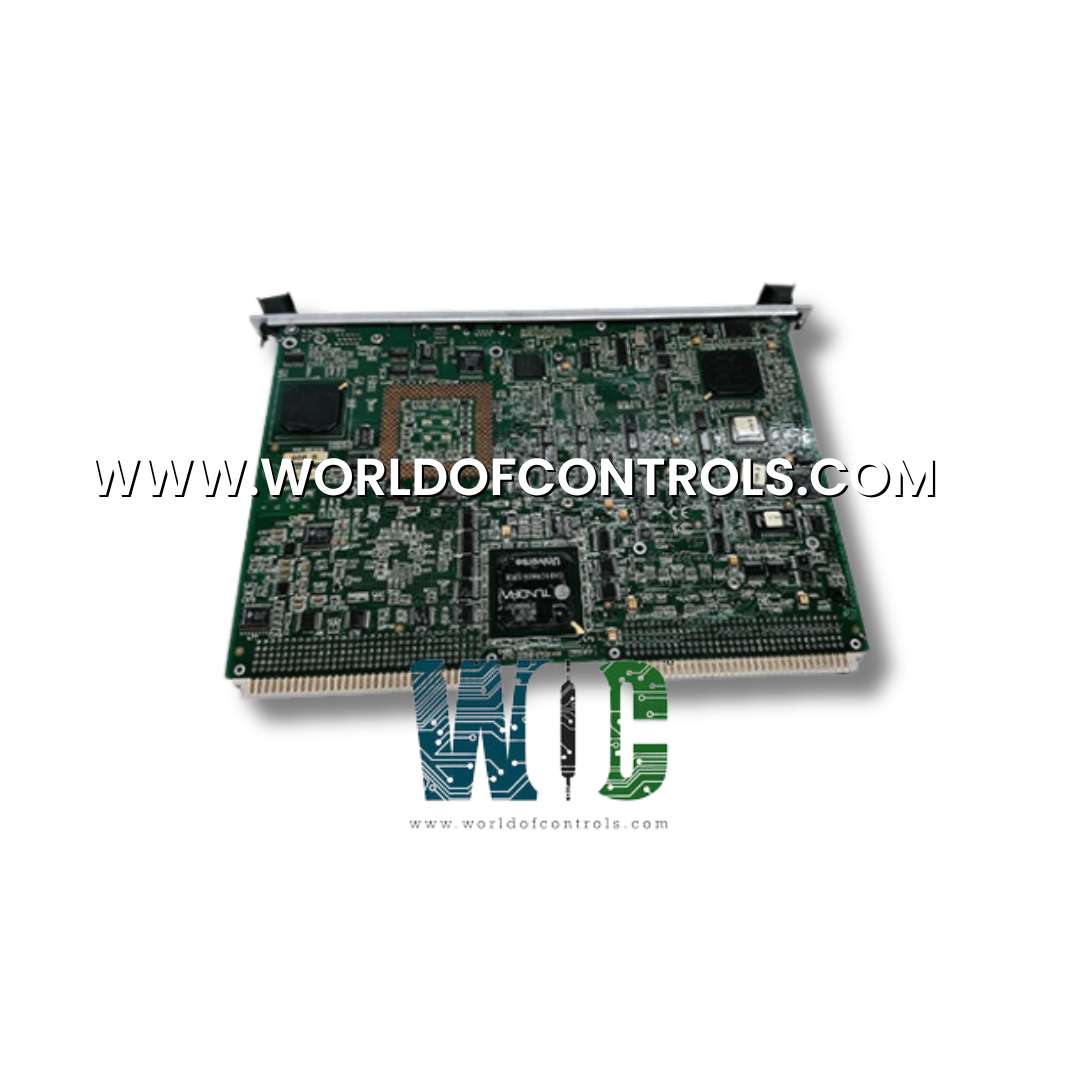

IS210SCSAS1A - I/O Expansion Board is available in stock which ships the same day.

IS210SCSAS1A - I/O Expansion Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210SCSAS1A - I/O Expansion Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS210SCSAS1A

Manufacturer: General Electric

Series: Mark VIeS

Product Type: I/O Expansion Board

Interface: Serial link to TCSA terminal board

Analog Inputs (Powered): 10 channels, 4-20 mA, 24 V DC

Analog Inputs (External): 6 channels, 4-20 mA

Thermocouple: Inputs 3 channels

Contact Inputs: 3 channels

Operating temperature: -30 to 65 °C

Repair: 3-7 days

Availability: In Stock

Country of Origin: United States

Manual: GEH-6723P

FUNCTIONAL DESCRIPTION:

IS210SCSAS1A is an I/O Expansion Board manufactured and designed by General Electric as part of the Mark VIeS Series used in GE Distributed Turbine Control Systems. The SCSA I/O expansion board connects through serial links to the TCSA terminal board and provides a wide range of input and output capabilities for turbine control applications. Each board supports ten 4-20 mA inputs with corresponding 24 V DC transmitter power outputs, six 4-20 mA inputs for externally powered transmitters, three thermocouple inputs for precise temperature monitoring, three contact inputs for discrete signal acquisition, and three contact outputs for control functions. In Triple Modular Redundant (TMR) configurations, the YSIL can utilize any of the 4-20 mA analog inputs on the SCSA (AnalogInput01_R, S, or T through AnalogInput16_R, S, or T) as part of the Emergency Trip Relay (ETR) logic string, ensuring reliable integration of critical safety signals into turbine protection and trip functions.

OPERATION:

The I/O Expansion Board operates as an extension module that increases the input and output capacity of the turbine control system, ensuring seamless integration with the main controller through serial communication links. It provides a flexible mix of analog, digital, and contact interfaces, enabling reliable acquisition and transmission of field signals to the control system. Each board typically supports multiple 4-20 mA current inputs for both powered and externally powered transmitters, thermocouple inputs for temperature measurement, contact inputs for status monitoring, and contact outputs for control or interlock functions. In Triple Modular Redundant (TMR) configurations, these inputs can also be assigned to critical safety logic, such as the Emergency Trip Relay (ETR), ensuring accurate, redundant, and fail-safe operation.

SCSA ANALOG INPUT ACCURACY:

To test the accuracy of the YSIL I/O pack analog inputs, use a multimeter and a signal source capable of generating currents and voltages within the configured ranges, confirming the limits for 4-20 mA input types before testing. Apply the specified test values from the provided table to the configured I/O points without making configuration changes, and record the values read by the YSIL in the Input tab of the ToolboxST application for each input channel. The test is considered acceptable if all measured values are within 2% of the full-range input values; for out-of-range conditions, the ToolboxST application must display an alert in the Diagnostics tab and mark the affected channel as unhealthy.

SCSA COMPOSITE ANALOG TRIP TEST:

The YSIL can utilize any of the 4-20 mA analog inputs on the SCSA (AnalogInput01_R, S, or T through AnalogInput16_R, S, or T TMR input sets) within the Emergency Trip Relay (ETR) logic string. To properly configure these inputs as trip signals in the ToolboxST application, each channel (R, S, and T) must be set up individually. The user enables an SCSA analog input for tripping by setting TripEnab(CFG) = Enable, assigning a TripSetPoint(CFG) value that, when exceeded, will initiate an ETR trip, and defining a TripDelay(CFG) value that specifies the time duration the input must remain above the setpoint before the trip request is issued.

World of Controls offers the largest inventory of OEM replacement parts for GE Distributed Turbine Control Systems, including unused, rebuilt, and fully tested, repaired boards, all backed by a reliable warranty. Our expert team is available 24/7 to diagnose and repair faulty boards, supply high-quality replacements, and provide technical guidance to ensure seamless integration and peak turbine performance. Each component is rigorously tested to meet OEM specifications, helping minimize downtime and maintain reliable, efficient operation. For pricing, availability, or technical support, contact us by phone or email for prompt assistance.

What is the main function of the board?

The board acts as an I/O expansion module for GE Mark VIeS turbine control systems, increasing the number of analog, thermocouple, and contact inputs and outputs available. It enables reliable signal acquisition and control for monitoring turbine operations. The board ensures seamless integration with the main control system and supports safety and trip functions in critical applications.

How many analog inputs does the board support?

It provides 10 powered 4-20 mA inputs with 24 V DC transmitter power outputs and 6 additional 4-20 mA inputs for externally powered transmitters. Each input can be configured individually for specific sensors or control applications. The analog inputs are designed for precise measurement and reliable signal transmission to the controller.

Can the analog inputs be used for Emergency Trip Relay (ETR) logic?

Yes, any 4-20 mA input can be assigned to the Emergency Trip Relay logic in TMR configurations. Each channel (R, S, and T) must be configured separately in ToolboxST using TripEnab, TripSetPoint, and TripDelay parameters. This ensures that critical analog signals trigger the ETR reliably under fault conditions.

How many thermocouples and contact inputs/outputs are available?

The board supports 3 thermocouple inputs for temperature measurement, 3 contact inputs for status monitoring, and 3 contact outputs for control or interlock functions. These inputs and outputs provide flexible interfacing for various sensors and field devices. They are fully integrated into the turbine control system for accurate monitoring and control.