World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS210SAMBH1A - Control Acoustic Monitoring Terminal Board is available in stock which ships the same day.

IS210SAMBH1A - Control Acoustic Monitoring Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210SAMBH1A - Control Acoustic Monitoring Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

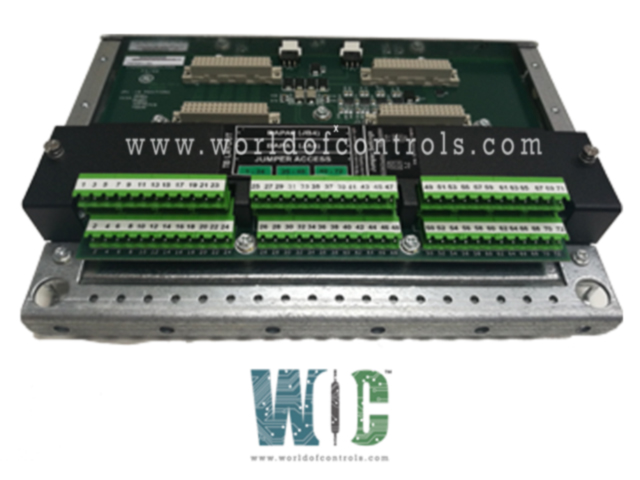

Part No: IS210SAMBH1A

Manufacturer: General Electric

Product Type: Control Acoustic Monitoring Terminal Board

Power inputs: 2 P28 inputs

DC output gain: 1

Allowable Offset on Outputs: 30 mV

Series: Mark VIe

Input Channels: 18

Output Channels: 18

Output impedance: 40 Ω

Operating temperature: -30 to 65oC

Power Supply Voltage: 24 V dc

Board Size: 14.3 cm high x 23.1 cm

Weight: 0.45 kg

Availability: In Stock

Country of Origin: USA

Manual: GEH-6721_Vol_II

FUNCTIONAL DESCRIPTION:

IS210SAMBH1A is a Control Acoustic Monitoring Terminal Board manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. The Mark VIe Control Acoustic Monitoring (SAMB) terminal board is a duplex terminal board providing 18 inputs for the Acoustic Monitoring System. The SAMB provides two terminal points per input channel for 18 channels on 36 terminals. It also provides an additional 18 buffered outputs on 36 terminals to connect external instrumentation for monitoring the AC voltage signal that represents the dynamic pressure signals from the combustor. SAMB includes passive electromagnetic interference (EMI) filters to protect against very high-frequency noise generated by external sources. SAMB includes the following features:

INSTALLATION:

The SIGx line for the PCB sensors is connected to the continuous current supply via hardware jumpers. JPx hardware jumpers are present on each channel (where x equals the input number). To use the GE CCSA for Endevco sensors or any other voltage output device, the jumper must be in the CCSA position. When using a PCB sensor or any other current output device, the jumper should be in the PCB position.

OPERATION:

The SAMB inputs an ac voltage signal from the CCSA proportional to the dynamic pressure sensed by either an Endevco or PCB probe. SAMB also inputs the dynamic pressure directly from a PCB constant-current charge amplifier connected to a PCB probe as an ac voltage proportional to the combustion dynamics riding on a dc bias voltage. Each channel provides a 3.6 mA constant-current source that can be connected to SIGx (where x is the channel number) for the PCB charge amplifiers. The jumper JPx (where x equals the channel number) is a two-pole jumper that controls the constant-current power supply and whether RETx is tied to the power ground, PCOM. When JPx is in the CCSA position, the constant-current is disabled and RETx is not tied to PCOM. When JPx is in the PCB position, the constant current is connected to SIGx, providing approximately 3.6 mA of current to power the PCB charge amplifier. The RETx line is tied to PCOM to provide a return path for the constant current.

WOC has the largest stock of OEM replacement parts for GE Distributed Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What is a Control Acoustic Monitoring Terminal Board?

A Control Acoustic Monitoring Terminal Board is an electronic device used to monitor and control acoustic signals in various environments. It is often used in industries like telecommunications, marine, and environmental monitoring to detect and analyze sound waves.

How does the Control Acoustic Monitoring Terminal Board work?

The board receives acoustic signals through sensors or microphones, processes these signals using built-in algorithms, and then provides outputs that can be analyzed or used to control other systems.

What types of sensors are compatible with the Control Acoustic Monitoring Terminal Board?

The board is compatible with a variety of sensors, including hydrophones (underwater microphones), standard microphones, and other specialized acoustic sensors designed for specific applications.