World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS210DTAOH1A - Analog Output Simplex Terminal Board is available in stock which ships the same day.

IS210DTAOH1A - Analog Output Simplex Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS210DTAOH1A - Analog Output Simplex Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS210DTAOH1A

Manufacturer: General Electric

Series: Mark VIe

Product Type: Analog Output Simplex Terminal Board

Number of Channels: 8

Analog Output Current: 0-20 mA

Customer load resistance Up to 500 Ω burden

Number of outputs: 125 V dc

Technology: Surface Mount

Suppression: MOV across the solenoid

Trip interlock isolation: Optical isolation to 1500 V

Size: 8.6 cm wide x 16.2 cm high

Operating Temperature: 0 to 60°C

Repair: 3-7 Days

Availability: In Stock

Country of Origin: United States

Manual: GEH-6421H

FUNCTIONAL DESCRIPTION:

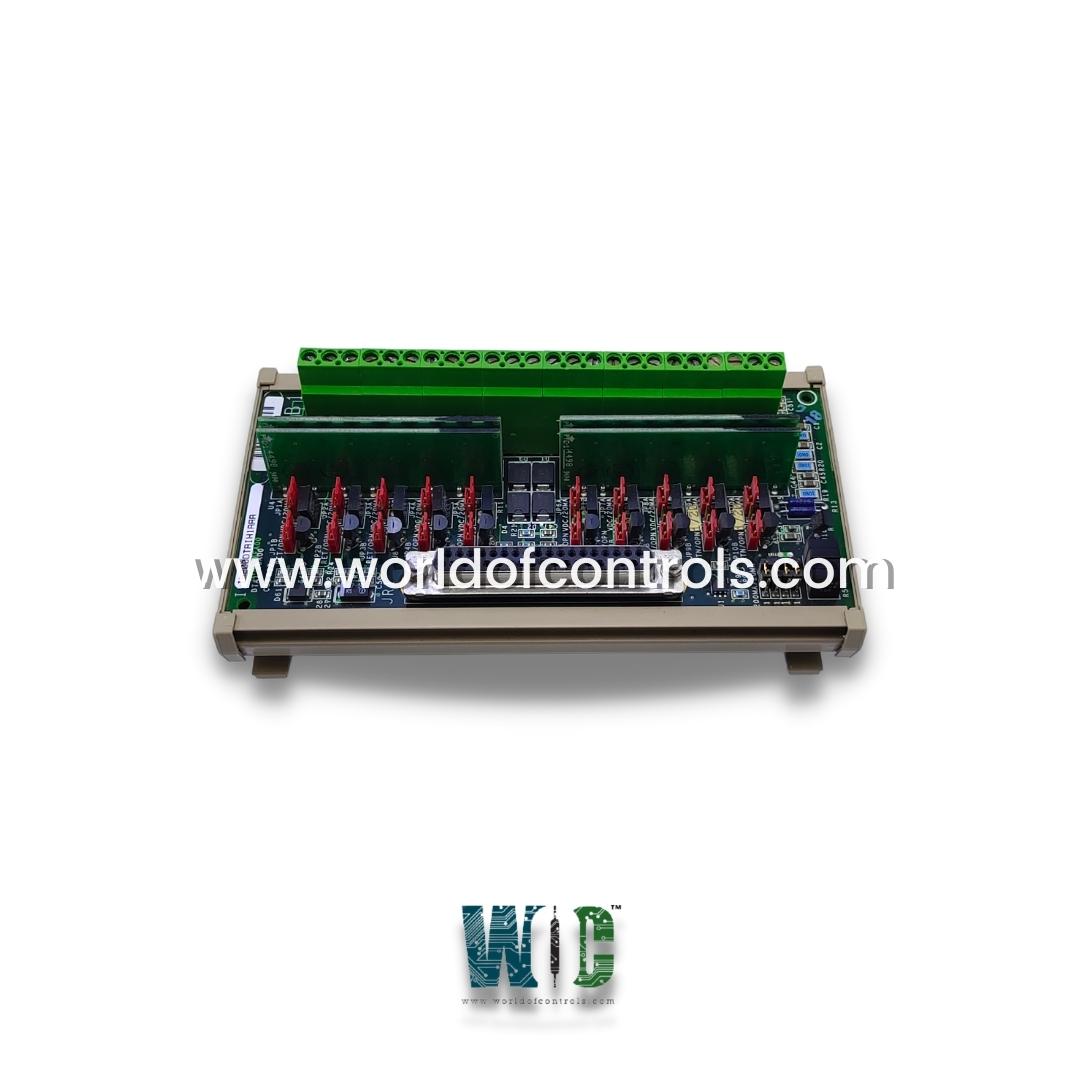

IS210DTAOH1A is an Analog Output Simplex Terminal Board manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Turbine Control Systems. The DTAO board is a compact and efficient analog output terminal board engineered for DIN-rail mounting, ideal for industrial automation systems requiring a streamlined footprint. Purpose-built for simplex configurations, the DTAO interfaces exclusively with the VAOC I/O board, ensuring precise and reliable analog signal transmission. Equipped with eight analog output channels, the DTAO receives control signals from the VAOC through a single 37-pin D-type connector cable, which is also compatible with the larger TBAO terminal board. For applications requiring additional analog outputs, the system supports the connection of two DTAO boards per VAOC, enabling up to 16 channels of analog output in a modular and scalable configuration.

The DTAO employs high-density Euro-block terminal blocks that are securely mounted to the board, providing durable and vibration-resistant wire terminations. Dual SCOM (signal common) screw terminals offer dependable grounding points, contributing to improved signal integrity and reduced susceptibility to electrical noise. Internally, the DTAO incorporates advanced noise suppression and signal conditioning circuitry, identical to that found in the TBAO, ensuring stable operation even in electrically noisy environments typical of industrial control cabinets. A built-in identification (ID) chip communicates with the VAOC to facilitate automatic board recognition, enabling efficient system diagnostics, error detection, and simplified configuration during commissioning. The DTAO's compact design, robust electrical characteristics, and dedicated compatibility with the VAOC make it an optimal choice for distributed control architectures that demand reliable analog output performance in space-constrained environments.

INSTALLATION:

The DTAO board slides into a plastic holder, which mounts on the DIN-rail. The eight analog outputs are wired directly to the terminal block, as shown in the following figure. Driven devices should not exceed a resistance of 500 Ω and can be located up to 300 m (984 ft) from the turbine control cabinet. The Euro-block type terminal block has 36 terminals and is permanently mounted on the terminal board. Typically, #18 AWG wires (shielded twisted pair) are used. There are two screws for the SCOM (ground) connection which should be as short a distance as possible. DIN-type terminal boards can be stacked vertically on the DIN-rail to conserve cabinet space.

OPERATION:

The DTAO module is designed to support up to 8 analog control outputs. Each output channel is equipped with a local loop current sense resistor, across which the voltage drop is continuously monitored. This feedback signal is transmitted to the VAOC (Voltage-to-Analog Output Controller), which uses it to regulate the output current. The VAOC houses the digital-to-analog (D/A) converter and output driver circuits responsible for generating and maintaining accurate analog current signals. The overall system design ensures high precision, real-time feedback control, and enhanced noise immunity, making the DTAO module suitable for critical industrial automation applications where accurate analog signal generation and robust operation are essential.

WOC has the largest stock of OEM Replacement Parts for GE Distributed Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

How does the DTAO board indicate output current?

The board utilizes the voltage drop across a series resistor to indicate output current, providing a reliable method for monitoring current flow. Additionally, the VAOC generates a diagnostic alarm if either of the two outputs becomes unhealthy, ensuring prompt identification of potential issues.

How does the terminal board ensure compatibility and prevent hardware incompatibility?

Each cable connector on the terminal board is equipped with its ID device, containing essential information such as the board's serial number, type, revision, and connector location. During system initialization, the VAOC interrogates these ID devices. If a mismatch is detected, a hardware incompatibility fault is generated, ensuring seamless compatibility and preventing system malfunctions.

How is the current controlled for each output on the DTAO board?

For each output, the board measures the voltage drop across a local loop current sense resistor. This measurement is then fed back to the VAOC processor, which regulates the current to ensure accurate and stable output levels.

How does the board mitigate noise and surge on each output?

To maintain signal integrity, filters are employed on each output to reduce high-frequency noise and suppress surge near the point of signal exit. This ensures that the analog signals remain clean and free from interference, enhancing the reliability of the output signals.