SPECIFICATIONS

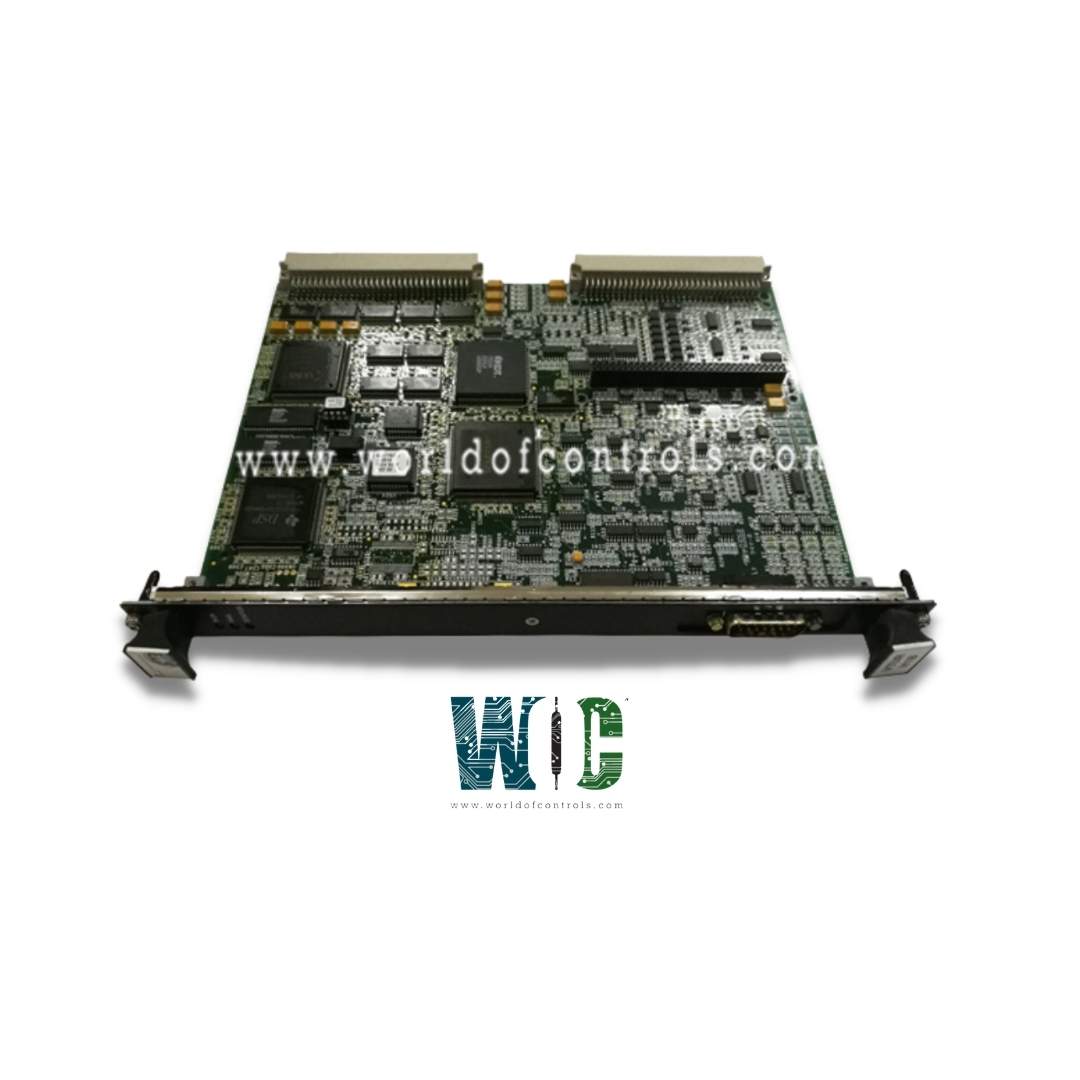

Part No.: IS200VTURG1B

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

MPU pulse rate range 2 Hz to 20 kHz

MPU pulse rate accuracy 0.05 percent

MPU input circuit sensitivity 27 mV pk

Flame detectors: 8 per VTUR

Temperature rating: 0 to 60 oC

Product Type: turbine specific primary trip board

Availability: In Stock

Series: Mark VI

Functional Description

IS200VTURG1B is a turbine specific primary trip board developed by GE. It is a part of Mark VI control system. It employs four passive pulse rate devices to accurately measure the speed of the turbine. These measurements are transmitted to the controller, which utilizes this data to generate the primary overspeed trip signal. This overspeed trip mechanism acts as a crucial safety feature, ensuring that the turbine does not exceed safe operational speeds, thereby preventing potential damage or catastrophic failure.

Features

- Generator Synchronization and Breaker Closure: Additionally, it facilitates the automatic synchronization of the generator.Once synchronization is achieved, it coordinates the closure of the main breaker, allowing the generated power to be efficiently transmitted through the electrical system.

- Monitoring Shaft Voltage and Current: Equipped to monitor the induced voltage and current on the turbine shaft. This monitoring capability is vital for detecting any irregularities or abnormalities in the turbine's operation, enabling timely intervention to prevent damage or malfunction.

- Flame Detection: In gas turbine applications, oversees the operation of eight Geiger Mueller flame detectors. These detectors, connected to the TRPG, are supplied with 335 V DC and 0.5 mA from an external source. The function of these detectors is to detect the presence or absence of flames within the turbine, providing critical information for maintaining safe combustion processes.

- Overspeed Trip Control: Controlling the primary overspeed trip relays on the TRPG terminal board. It generates the trip signal based on the turbine speed measurements and other relevant parameters. This trip signal is then transmitted to the TRPG, initiating the activation of emergency solenoids to trigger the turbine overspeed trip. Notably, it can receive overspeed trip signals from both itself and VPRO, providing redundancy and enhancing system reliability.

- Interface with Electrical Trip Devices (ETD): Within the TRPG, nine magnetic relays interface with three trip solenoids, collectively known as Electrical Trip Devices (ETD). These relays, nine in total for Triple Modular Redundancy (TMR) systems and three for simplex systems, serve to ensure the reliable operation of the trip mechanisms. By coordinating with VTUR and other components, the ETDs play a crucial role in swiftly and effectively executing turbine shutdown procedures in response to critical events like overspeed conditions.

Installation

- Power Down the VME Processor Rack:Prior to installation, it's crucial to power down the VME processor rack to prevent any electrical interference or potential damage to the components. This step involves safely shutting down any associated systems and disconnecting power sources to the VME rack to ensure a secure installation environment.

- Slide in the Board: With the VME processor rack powered down, the next step is to carefully slide the board into the designated slot within the rack. Precision is key during this process to align the board correctly with the slot and ensure a proper fit. Once the board is positioned correctly, apply gentle pressure to push the top and bottom levers in with your hands. This action secures the edge connectors of the board firmly in place within the slot, establishing electrical connectivity with the rack and other components.

- Secure with Captive Screws:After seating the board in the slot, the final step is to secure it in position by tightening the captive screws located at the top and bottom of the front panel.Captive screws are designed to remain attached to the panel even when loosened, simplifying the installation process and reducing the risk of misplaced hardware. Tightening these screws ensures that the board remains securely fastened within the rack, minimizing the potential for displacement or instability during operation.

Fast Overspeed Trip

- PR_Single: This algorithm utilizes redundant VTUR packs, distributing the workload across two separate boards. Each redundant PR (Pulse Rate) transducer is assigned to one board, ensuring redundancy and enhancing reliability. PR_Single is the preferred algorithm for LM (Land and Marine) gas turbines, offering a robust overspeed protection mechanism tailored to the specific requirements of these turbines.

- PR_Max: In contrast to PR_Single, PR_Max utilizes a single VTUR pack connected to two redundant PR transducers. This configuration allows for broken shaft detection and deceleration protection while mitigating the risk of nuisance trips in the event of transducer failure. PR_Max offers a balanced approach, combining effective overspeed protection with enhanced fault tolerance, thereby ensuring the uninterrupted operation of the turbine under diverse operating conditions.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200VTURG1B?

It is a turbine specific primary trip board developed by GE under the Mark VI series.

What happens if the feedback from the solenoid relay drivers differs from the control signal?

If there's a discrepancy between the feedback from the solenoid relay drivers and the control signal, a fault is triggered. This ensures that any inconsistencies in the solenoid operation are promptly detected and addressed.

How are faults handled when the feedback from relay contacts doesn't match the control signal?

In such cases, a fault is generated. This mechanism is crucial for maintaining the integrity of the relay operations and promptly identifying any deviations that may occur during the control process.

What occurs in the event of a loss of solenoid power?

Loss of solenoid power results in the creation of a fault. This serves as a safeguard against potential disruptions in the solenoid-driven operations, ensuring that any power loss is promptly identified and rectified.

Are there any specific conditions related to flame detector voltage that trigger faults?

Yes, both high and low flame detector voltage can create faults. This ensures that any anomalies in the flame detection system, whether due to excessive or insufficient voltage levels, are promptly flagged for attention and resolution.