SPECIFICATIONS

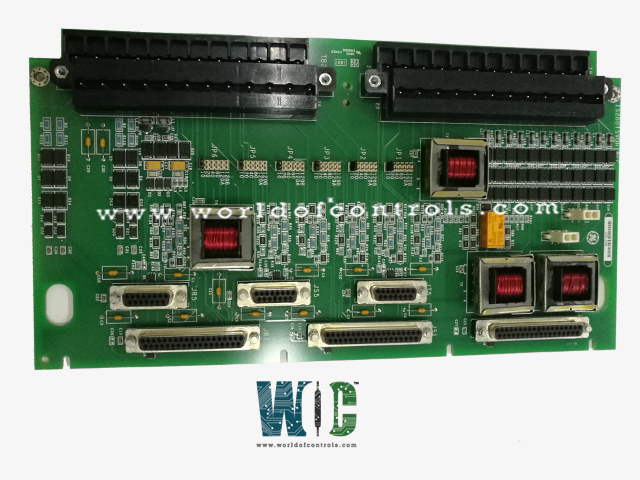

Part No.: IS200TSVOH1BCC

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Magnetic PR pickup signal: Generates 150 V p-p

Active PR Pickup Signal: Generates 5 to 27 V p-p

Size: 17.8 cm high x 33.02 cm wide

Technology: Surface mount

Number of inputs: 8

Number of outputs: 8

Power supply voltage: Nominal 24 V dc

LVDT excitation output Frequency: 3.2 kHz

LVDT excitation output Voltage: 7.00

Product Type: Servo Terminal Board

Availability: In Stock

Series: Mark VI

Functional Description

IS200TSVOH1BCC is a Servo Terminal Board developed by GE. It is a part of Mark VI control system. The Servo Terminal Board (TSVO) serves as a crucial interface component within the system, facilitating the operation of electro-hydraulic servo valves responsible for actuating steam/fuel valves. By effectively interfacing with electro-hydraulic servo valves, facilitating valve position measurement, and providing robust communication and signal distribution capabilities, the Servo Terminal Board (TSVO) plays a vital role in ensuring the reliable and efficient operation of the steam/fuel valve control system. Its integration of Simplex and TMR signals, along with support for external trip inputs, further enhances system resilience and safety in demanding industrial environments.

Features

- Valve Actuation and Position Measurement: Interfaces directly with two electro-hydraulic servo valves, which play a pivotal role in controlling the operation of steam/fuel valves within the system. Additionally, valve position is measured using linear variable differential transformers (LVDT), ensuring precise control and monitoring of valve positions.

- Communication with I/O Processor (VSVO): Two cables connect to the I/O processor (VSVO), utilizing the J5 plug located on the front of VSVO and the J3/4 connectors on the VME rack. This communication pathway enables seamless data exchange and coordination between TSVO and the I/O processor, facilitating integrated system operation.

- Signal Distribution: Provides both Simplex and TMR (Triple Modular Redundancy) signals to ensure redundancy and fault tolerance in critical operations. Simplex signals are routed through the JR1 connector, while TMR signals are fanned out to the JR1, JS1, and JT1 connectors. This configuration enhances system reliability by providing redundant signal paths and fault detection capabilities.

- External Trip Capability: Plugs JD1 or JD2 on TSVO are designated for external trip inputs from the protection module. This feature allows for additional safety measures by enabling the system to respond to external trip signals, such as those triggered by emergency shutdown protocols or protective measures.

LVDT Excitation Output

- Frequency Stability: The excitation output operates at a consistent frequency of 3.2 kHz, ensuring reliable performance across various operating conditions. With a tight tolerance of ±0.2 kHz, the excitation frequency remains within specified limits, minimizing deviations and ensuring consistent sensor operation.

- Voltage Output: The excitation output maintains a stable voltage level of 7.00 V rms, crucial for proper operation of LVDT sensors. With a narrow tolerance of ±0.14 V, the voltage output remains precisely regulated, minimizing fluctuations and ensuring accurate sensor readings. This precise voltage control is essential for achieving reliable and repeatable measurements.

- LVDT Sensor Compatibility: The excitation output is designed to interface seamlessly with LVDT sensors, providing the necessary voltage and frequency signals for optimal sensor performance. By delivering stable and accurate excitation signals, the output ensures consistent and reliable measurement of position or displacement, contributing to the overall accuracy and reliability of the system.

- Precision and Stability: Maintaining tight tolerances on both frequency and voltage output is crucial for ensuring the precision and stability of LVDT measurements. The precise control of excitation frequency and voltage minimizes variations in sensor response, resulting in accurate and repeatable measurements over time.

Pulse Rate Input

- Signal Dependency on Frequency: The minimum signal required for proper measurement varies depending on the frequency of the pulse rate input. At a lower frequency of 2 Hz, the minimum signal amplitude needed for accurate measurement is 33 mVpk. This ensures that even at lower frequencies, the system can reliably detect and measure pulse rate inputs.

- Frequency-Dependent Sensitivity: As the frequency of the pulse rate input increases to 12 kHz, the minimum required signal amplitude also increases to 827 mVpk. This sensitivity to frequency variations ensures that the system can accurately capture and process pulse rate inputs across a wide range of operational frequencies, maintaining precision and reliability under varying conditions.

- Ensuring Accuracy and Reliability: By specifying minimum signal requirements based on frequency, the Pulse Rate Input feature ensures accurate measurement and monitoring of pulse rates under diverse operating conditions. This sensitivity to signal amplitudes at different frequencies helps maintain measurement accuracy and reliability, enabling the system to effectively track pulse rate variations and respond accordingly.

- Adaptability to Operational Conditions: The varying minimum signal requirements cater to the dynamic nature of pulse rate inputs, allowing the system to adapt to changes in frequency and ensure consistent measurement performance across different operational scenarios. This adaptability enhances the versatility and robustness of the system, enabling it to effectively handle pulse rate monitoring tasks in a wide range of applications.

Fault Detection

- Comprehensive Fault Detection: The system incorporates a range of fault detection mechanisms to identify and address potential issues promptly. These mechanisms are designed to detect various fault conditions that could compromise system integrity or performance.

- Servo Current Out of Limits or Non-Responsive Behavior: One aspect of fault detection involves monitoring servo currents to ensure they remain within predefined limits. If the servo current exceeds these limits or exhibits non-responsive behavior, indicating a potential malfunction or abnormality, the system triggers a fault condition. This proactive monitoring helps prevent servo-related issues and ensures smooth operation of the system.

- Regulator Feedback Signal Exceeding Predefined Limits: Another critical aspect of fault detection involves monitoring regulator feedback signals to detect any deviations from predefined limits. If the feedback signal exceeds these limits, indicating a regulatory malfunction or abnormality, the system identifies this as a fault condition. By promptly detecting and addressing such deviations, the system maintains stable regulation and operational consistency.

- Detection of Failed ID Chip: Additionally, the system is equipped to detect the failure of ID chips associated with system components. These chips contain essential identification information, including serial numbers and revision numbers. If a failure in the ID chip is detected, indicating a potential communication or identification issue, the system flags this as a fault condition. This proactive detection helps prevent communication errors and ensures accurate identification of system components.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200TSVOH1BCC?

It is a Servo Terminal Board developed by GE under the Mark VI series.

How are Servo Outputs Configured for Simplex Systems?

In a simplex system, each servo output is configured individually. Servo 1 is configured with jumper JP1, and Servo 2 is configured with jumper JP4 to set the correct coil current.

What about TMR Systems?

In a TMR system, each servo output can have three coils for redundancy. For Servo 1, coil currents are jumper selected using JP1-3, and for Servo 2, they are selected using JP4-6. This configuration ensures redundancy and fault tolerance in the system, enhancing reliability.

How is the Configuration Process Handled?

All other servo board configurations, including those for TMR systems, are performed using the toolbox. The toolbox provides a user-friendly interface for configuring various parameters and settings, ensuring ease of use and accuracy in system setup.