SPECIFICATIONS

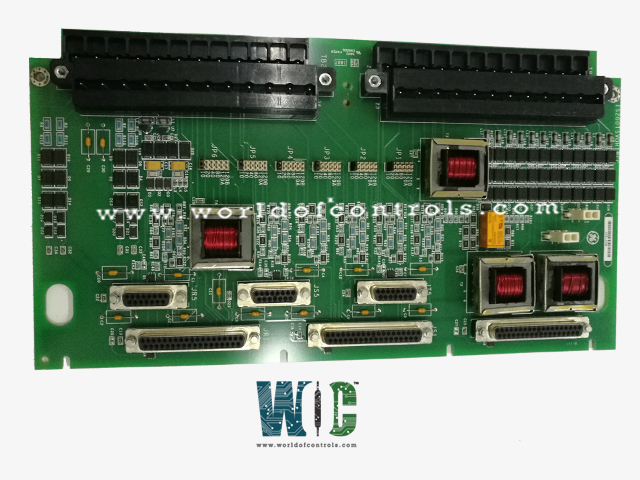

Part No.: IS200TSVOH1BCB

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature Operating: -30 to 65 o C

Power supply voltage: Nominal 24 V dc

Size: 17.8 cm high x 33.02 cm wide

Technology: Surface mount

Product Type: Servo Terminal Board

Availability: In Stock

Series: Mark VI

Functional Description

IS200TSVOH1BCB is a servo terminal board developed by GE. It is a part of Mark VI control system. The Servo Terminal Board plays a crucial role in facilitating the interface between electro-hydraulic servo valves and the control system responsible for actuating steam/fuel valves. Its primary function involves coordinating valve positions using Linear Variable Differential Transformers (LVDTs) to ensure precise control over these critical components. Its connections to the I/O processor, signal distribution, and provision for external trip signals underscore its role in ensuring accurate and reliable functionality within the broader system.

Valve Actuation Mechanism

- Electro-Hydraulic Servo Valves: TSVO interfaces with two electro-hydraulic servo valves responsible for manipulating the steam/fuel valves. These valves, controlled by the TSVO, regulate the flow and operation of steam or fuel within the system.

- LVDT Measurement: The board employs LVDTs to measure the position of these valves accurately. These sensors ensure precise feedback regarding the valve positions for effective control and monitoring.

I/O Processor Connection

- Cable Connections to VSVO: Two cables establish connections between TSVO and the I/O processor (VSVO). These cables utilize the J5 plug located on the front of the VSVO and connect to the J3/4 connectors situated on the VME rack.

- These connections serve as a communication pathway between the TSVO and the I/O processor.

Signal Distribution and Connectors

- Signal Distribution: TSVO functions by providing Simplex signals through the JR1 connector. Additionally, it distributes Triple Modular Redundancy (TMR) signals across the JR1, JS1, and JT1 connectors. This distribution mechanism ensures redundancy and reliability in signal transmission.

- External Trip Plugs: The board includes JD1 or JD2 plugs designated for an external trip, possibly originating from the protection module. These connectors might serve as an interface point for an external trip signal, adding an extra layer of safety or control to the system.

Key Connections

- LVDT Measurements: Utilizes LVDTs (Linear Variable Differential Transformers) for precise valve position measurements. These LVDTs play a critical role in monitoring and controlling valve positions within the system, ensuring accurate operation and control.

- I/O Processor Connectivity: For I/O processor connectivity, it leverages the J5 plug on the VSVO (Valve Servo) module and the J3/4 connectors on the VME (Versa Module Eurocard) rack. These connections facilitate seamless communication between the component and the I/O processor, enabling efficient data exchange and control functionalities.

- Signal Distribution: Signal distribution is managed through various connectors depending on the system configuration. Simplex signals are transmitted via the JR1 connector, providing a straightforward communication pathway for essential signals. In contrast, TMR (Triple Modular Redundant) signals are spread across multiple connectors, including JR1, JS1, and JT1. This distribution strategy ensures redundancy and reliability in signal transmission, enhancing system robustness and fault tolerance.

- External Trip Connections: It offers external trip connections through plugs JD1 or JD2, enabling potential interface with the protection module's external trip signal. These connections facilitate the integration of external trip signals into the system, enhancing safety and protection functionalities by allowing for rapid response to critical events or abnormal conditions.

Installation Procedure

- Terminal Block Wiring for Sensors and Servo Valves: The sensors and servo valves are directly wired to two I/O terminal blocks securely mounted on the TSVO. Each block is firmly fastened with two screws and accommodates up to 12 AWG wiring through its 24 terminals. Adjacent to these terminal blocks, shield termination strips, connected to chassis ground, provide essential grounding and shielding for these connected components, maintaining system integrity.

- External Trip Wiring and Interface: External trip wiring connections are established by plugging into designated ports, JD1 or JD2, strategically positioned on the TSVO. These ports serve as interfaces for potential external trip signals, enabling additional safety measures, possibly originating from the protection module, to be integrated seamlessly into the system.

- Servo Output Configuration: Each servo output on the TSVO can be configured in a Triple Modular Redundancy (TMR) setup, allowing for three coils per output. Configuration adjustments, such as current settings for these coils, are made using jumper selection via JP1-6, providing flexibility in managing current flow to suit operational requirements.

- Cable Connections to VSVO Board and VME Rack: Cable connections play a pivotal role in establishing communication pathways within the system:

- Cables from J5 connectors are directed to the front of the VSVO board in racks R, S, T. These connections facilitate efficient data transfer and communication between the TSVO and the VSVO board.

- Cables from J1 connectors are routed to the VME rack located below the VSVO in racks R, S, T. These connections likely facilitate additional data transmission or control functionalities within the system, ensuring seamless integration and operational efficiency.

- By adhering to these installation guidelines, including precise wiring, grounding considerations, interface provisions for external signals, servo output configuration, and strategic cable connections, the TSVO ensures a robust and functional interface between critical system components and control interfaces, contributing to the system's reliability and operational integrity.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200TSVOH1BCB?

It is a servo terminal board developed by GE under the Mark VI series.

How many LVDT valve position inputs can the TSVO handle?

It is equipped to handle up to six LVDT valve position inputs. These inputs serve as the basis for monitoring and controlling the positions of various valves within the system.

What is the LVDT configuration capability for each servo control loop?

The module offers flexibility in configuring LVDTs for each servo control loop. Users have the option to choose between utilizing one, two, three, or four LVDTs for each control loop. This flexibility allows for tailored and precise control over valve positions based on system requirements.

How are multiple LVDT inputs utilized when three inputs are employed?

When three inputs are utilized within a control loop, they are specifically earmarked for gas turbine flow measurement applications. These signals pass through the TSVO and directly connect to the front of the VSVO board at J5. This configuration highlights the specialized use of these inputs for gas turbine flow measurement purposes, optimizing functionality and data transmission directly to the VSVO board.