World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

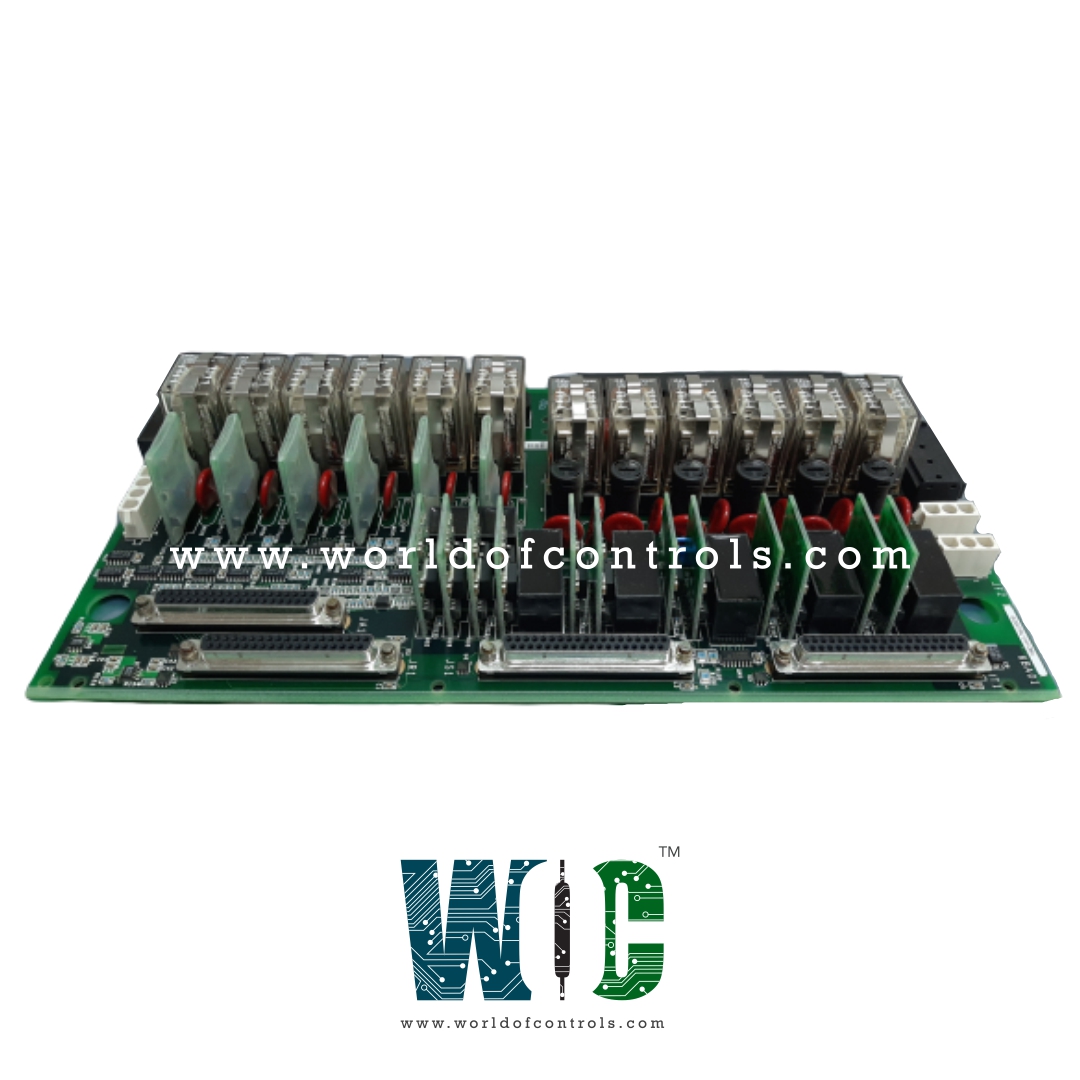

IS200TRLYH1DAC - Simplex Contact Output Terminal Board is available in stock which ships the same day.

IS200TRLYH1DAC - Simplex Contact Output Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TRLYH1DAC - Simplex Contact Output Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200TRLYH1DAC

Manufacturer: General Electric

Series: Mark VIe

Function: Relay Output with Coil Sensing Terminal Board

Number of relay channels: 12

Rated voltage on relays: 125 V dc

Dimensions: 17.8 cm wide x 33.02 cm high

Operating Temperature: -30 to + 65 °C

Controller and I/O module Redundancy: Simplex

Internal operating system: QNX

Power Consumption: 4 W

Analog outputs: 0 to 10 V

Configuration Software: ToolboxST

Country of Manufacture: United States (USA)

Availability: In Stock

Manual: GEH-6721D

FUNCTIONAL DESCRIPTION:

IS200TRLYH1DAC is a Relay Output with Coil Sensing Terminal Board manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. TRLYH1DAC holds 12 plug-in magnetic relays. The first six relay circuits can be configured as jumpers for either dry, Form-C contact outputs or to drive external solenoids. A standard 125 V dc or 115/230 V ac source, or an optional 24 V dc source, with individual jumper-selectable fuses and on-board suppression can be provided for field solenoid power. The next five relays (7-11) are unpowered isolated Form-C contacts. Output 12 is an isolated Form-C contact, used for special applications such as ignition transformers. In the Mark VIe system, the PDOA I/O packs work with the TRLY board. The PDOA packs plug into the DC-37 pin connectors on the terminal board. A single PDOA on JA1 or three PDOAs on JR1, JS1, and JT1 are supported.

INSTALLATION:

The 12 relay outputs are wired directly to two I/O terminal blocks mounted on the terminal board, as shown in the following figure. Each block is held down with two screws and has 24 terminals accepting up to #12 AWG wires. A shield terminal strip attached to chassis ground is located on the left side of each terminal block. Solenoid power for outputs 1-6 is normally plugged to JF1. JF2 can be used to daisy chain power to other TRLYs. Alternatively, customer power may be wired directly into TB3 when power is not plugged into JF1/JF2. JG1 provides power to the customer's special solenoid, output 12. Jumpers JP1-JP6 are removed in the factory and shipped in a plastic bag. Reinstall the appropriate jumper if power to a field solenoid is required. Conduct individual loop energization checks as per standard practices, and install the jumpers as required. The fuses should be removed for isolated contact applications to ensure that suppression leakage is removed from the power bus.

OPERATION:

Relay drivers, fuses, and jumpers are mounted on the relay terminal board. For simplex operation, D-type connectors carry control signals plus monitor feedback voltages between the I/O processors and TRLY through JA1. Relays are driven at the frame rate and have a 3.0 A rating. The rated contact-to-contact voltage is 500 V ac for one minute, and the rated coil-to-contact voltage is 1,500 V ac for one minute. The typical time to operate is 10 ms. Relays 1-6 have a 250 V MOV for transient suppression between the normally open and the power return terminals. The relay outputs have failsafe features when a cable is unplugged or communication with the associated I/O processor is lost. The inputs vote to de-energize the corresponding relays. For TMR applications, relay control signals are fanned into TRLY from the three I/O processors R, S, and T through plugs JR1, JS1, and JT1. These signals are voted on, and the result controls the corresponding relay driver. Power for the relay coils comes in from all three I/O processors and is diode-shared.

WOC maintains one of the industries largest inventories of OEM replacement parts for GE Distributed Turbine Control Systems, ensuring fast access to components for maintenance, upgrades, and replacements. We supply unused, professionally rebuilt, and fully tested boards backed by a dependable warranty, along with expert repair services and technical support. Our team is available around the clock to help minimize downtime and maintain optimal system performance. For pricing, availability, or technical guidance, please contact the WOC team via phone or email—we are committed to providing fast, reliable, and effective solutions for all your automation needs.

What is an IS200TRLYH1DAC (Relay Output with Coil Sensing Terminal Board)?

It is a terminal board designed to control relay outputs while monitoring coil status for reliable operation. The board typically includes multiple Form-C relays that can be configured for dry contacts or solenoid-driving applications. Coil sensing allows the system to detect relay health, energization state, and wiring integrity.

How does coil sensing work on this terminal board?

Coil sensing monitors the electrical condition of each relay coil to ensure proper energization. It detects issues such as open circuits, short circuits, or loss of drive signals. This feature enhances diagnostic capability and improves system reliability by identifying faults early.

What types of relay outputs are supported?

Most boards support a mix of powered and unpowered Form-C relay outputs. The first set of relays may be configured for solenoid loads, while the remaining relays provide isolated contact outputs for general-purpose control. Special relays may also be provided for high-demand applications like ignition transformers.