World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200TREGH3B - Turbine Emergency Trip Board is available in stock which ships the same day.

IS200TREGH3B - Turbine Emergency Trip Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TREGH3B - Turbine Emergency Trip Board, contact us and we will get back to you within 24 hours.

Part No.: IS200TREGH3B

Manufacturer: General Electric

Series: Mark VI

Trip interlock isolation: Optical isolation to 1500 V

Trip interlock filter: Hardware filter, 4 ms

Trip interlock ac voltage rejection: 60 V rms

Size: 17.8 cm wide x 33.02 cm, high

Number of trip solenoids: Three

Availability: In Stock

Country of Manufacture: United States (USA)

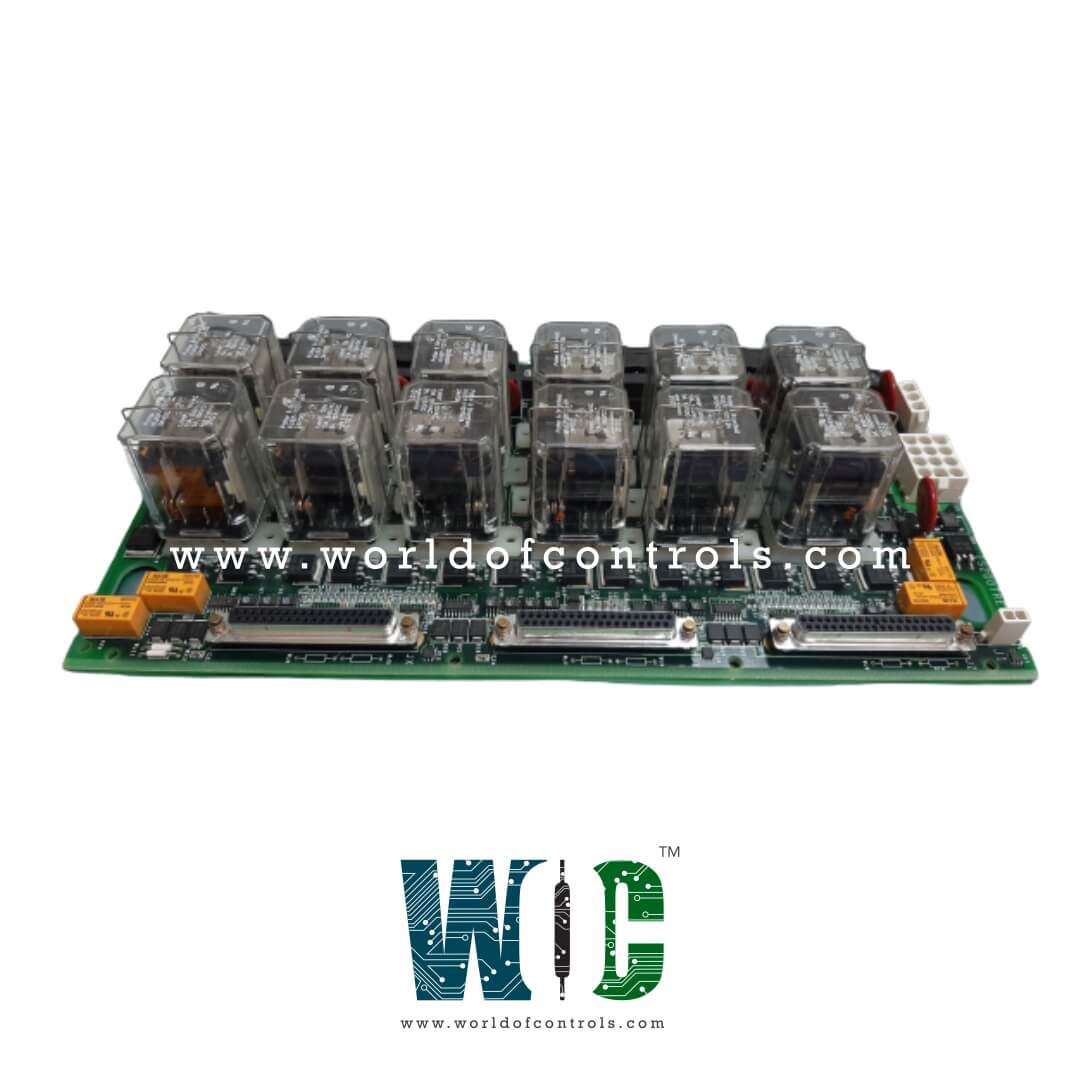

IS200TREGH3B is a Turbine Emergency Trip Board developed by GE. It is a part of mark VI control system. The module is responsible for providing power to the emergency trip solenoids and ensuring safe and reliable operation. Controlled by the I/O controller, the module plays a pivotal role in executing essential emergency functions and coordinating critical relay operations. The primary function of TREG is to supply power to three emergency trip solenoids. These solenoids serve as critical components for initiating the emergency trip of the turbine in case of potential hazards or overspeed conditions. The TREG module is designed to deliver the positive side of the dc power required to actuate these solenoids effectively.

World of Controls has the most comprehensive collection of GE Mark VI components. Please contact WOC as soon as possible if you require any extra information.

What is IS200TREGH3B?

It is a Turbine Emergency Trip Board developed by GE

What happens if any of the diagnostic values do not match the desired values?

If any of the diagnostic values do not agree with the desired values, the I/O controller detects a fault. This fault indicates a potential issue or deviation from the expected performance of the TREG board and its connected components. The fault notification prompts operators and maintenance personnel to investigate and address the problem promptly, ensuring the reliability and safety of the system.

How do the ID devices on connectors JX1, JY1, and JZ1 enhance compatibility and identification?

Connectors JX1, JY1, and JZ1 are equipped with ID devices that contain vital information. These read-only chips are coded with essential details such as the terminal board's serial number, board type, revision number, and plug location. The ID devices help ensure proper identification and compatibility checking when connecting to the I/O controller.

What happens if there is a mismatch encountered when reading the ID devices on TREG connectors?

When the I/O controller reads the ID device on any of the connectors (JX1, JY1, or JZ1) and identifies a mismatch, such as an incorrect serial number or plug location, a hardware incompatibility fault is generated. This fault indicates a potential issue with the connection or identification, alerting users to resolve the mismatch for proper system functioning.

How do these diagnostics and ID devices contribute to system reliability and maintenance?

The diagnostics performed by the I/O controller on the board and its connected devices ensure that any deviations or faults are promptly detected and addressed, preventing potential failures and enhancing system reliability. The presence of ID devices on connectors facilitates easy and accurate identification of terminal boards, streamlining maintenance activities and ensuring proper compatibility during system setup or upgrades.