SPECIFICATIONS

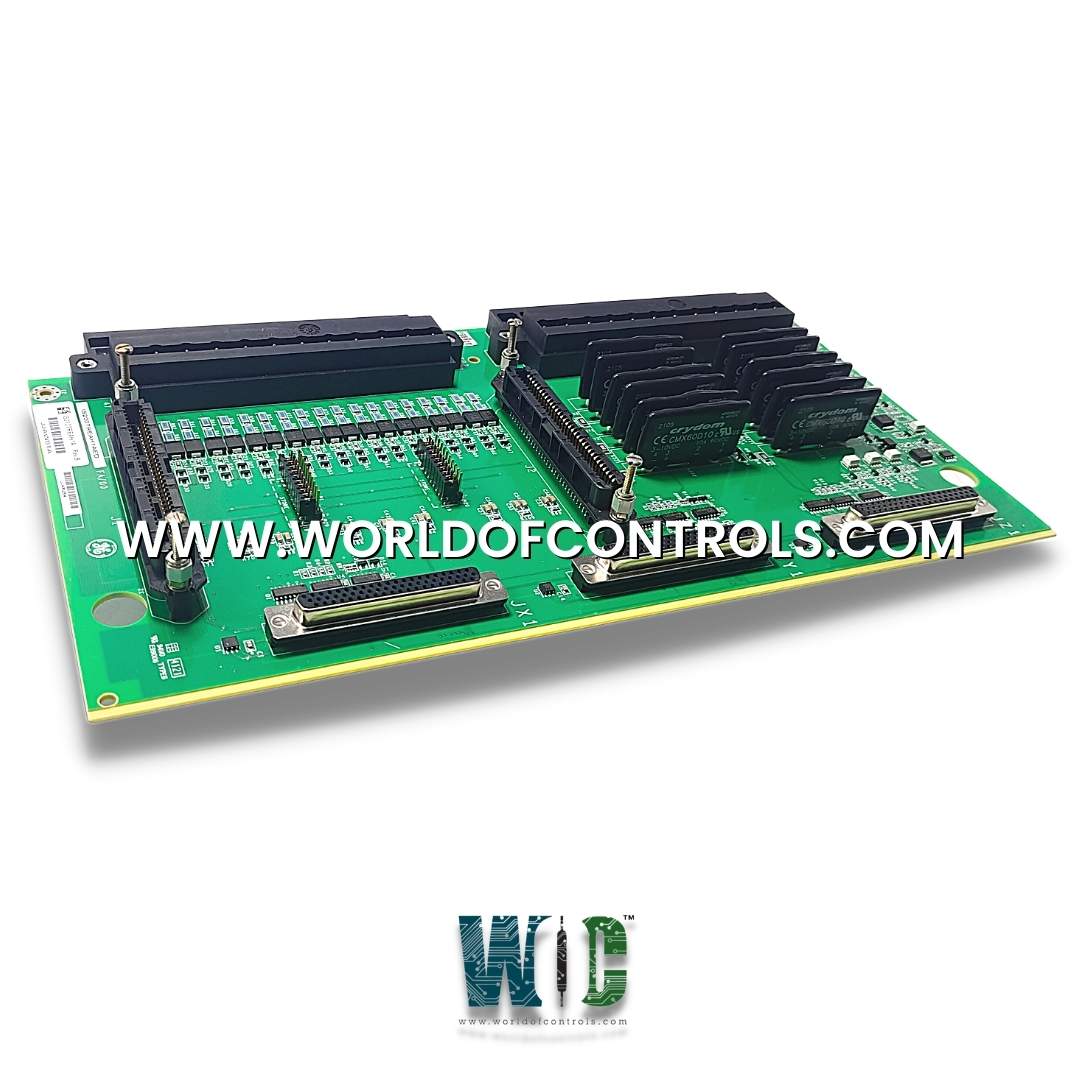

Part No.: IS200TREAS4A

Manufacturer: General Electric

Series: Mark VI

Size: 33.0 cm high x 17.8 cm, wide

Technology: Surface mount

MPU pulse rate range: 2 Hz to 20 kHz

MPU pulse rate accuracy: 0.05% of reading

MPU input circuit sensitivity: 27 mV pk

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

IS200TREAS4A is an Emergency Trip Terminal Board developed by GE. It is a part of mark VI control system. It features 48 pluggable Euro-style box terminals, allowing customers to interface with the system conveniently. These terminals serve as inputs, allowing customers to connect external devices or sensors to provide essential information and feedback to the control system. The terminal board is equipped with nine passive pulse rate devices, with three devices allocated per X/Y/Z section. These devices accurately sense the rotational speed of the turbine using toothed wheels. The measured speed information is critical for monitoring turbine performance and detecting any potential overspeed conditions, enabling the system to initiate emergency trip actions when necessary.

Features

- Jumper Blocks for Speed Inputs: To streamline and simplify the connection of speed inputs, it incorporates jumper blocks that enable the fanning of one set of three speed inputs to all three PPRO I/O packs. This efficient configuration ensures that the turbine's speed signals are distributed accurately and consistently to all relevant components for precise monitoring and protection.

- TMR Voted Output Contacts: Features two 24 V dc TMR (Triple Modular Redundancy) voted output contacts designed to trigger an emergency shutdown of the system if required. The TMR configuration ensures redundancy and fault tolerance, guaranteeing the reliability of the emergency trip functionality.

- Voltage Detection Circuits for Trip String: To monitor the trip string effectively, TREA incorporates four 24-125 V dc voltage detection circuits. These circuits play a crucial role in continuously checking the integrity of the trip string, ensuring that it functions as intended during emergencies.

- Daughterboards Connectors: Future-proofed for expansion and adaptability, featuring daughterboard connectors that allow for optional feature expansions. These connectors enable additional functionalities and upgrades to be seamlessly integrated into the system as per the evolving needs of the turbine control and protection requirements.

Voltage Monitors

- The turbine emergency trip terminal board offers a flexible and versatile solution for trip relays placement within the trip string circuit. As the trip string circuit is not fixed, TREA provides three general-purpose isolated voltage sensor inputs. These inputs can be utilized to monitor various points in the trip system and transmit the voltage status to the system controller, enabling appropriate actions to be taken based on the detected conditions.

- The general-purpose isolated voltage sensor inputs allow for customizable and adaptable monitoring applications. Users have the freedom to select and configure these sensor inputs as per the specific requirements of their turbine control system. While the typical use of these inputs may involve sensing the power supply voltage for the two trip strings (PWR) and the solenoid voltage of the device driven by the relays (SOL1, SOL2), their potential applications extend far beyond these examples.

- For instance, users can deploy these sensor inputs to monitor various critical parameters within the trip system, such as detecting voltage drops or fluctuations that could indicate potential issues in the circuit. By monitoring the power supply voltage (PWR), the system can ensure that the trip strings are receiving the required power levels for proper functioning. Additionally, sensing the solenoid voltage (SOL1, SOL2) provides real-time information about the device being driven by the trip relays, helping to verify its operational status and performance.

- Moreover, the general-purpose nature of these inputs allows users to freely apply them to best serve the specific application. They can be used to monitor other voltage signals, perform diagnostics, or provide additional safety features in the trip system, depending on the particular needs of the turbine control system.

Trip Input

- The Trip input in the PPRA (Programmable Protection Relay Assembly) is a critical feature that can be configured within the system's settings. This configuration allows the Trip input to either be required for operation or bypassed entirely, depending on the needs of the application. When enabled, the Trip input utilizes a hardware path within the PPRA, ensuring that the signal bypasses any processing delays that might arise from the firmware, providing faster response times and higher reliability in the system.

- For the Trip input to operate correctly, it must be powered by a clean and stable DC source, such as a battery or filtered rectified AC source with less than 5% ripple. This ensures that the input voltage remains stable and free from fluctuations that could impact the operation of the trip relays. A minimum of 18 V DC must be supplied to the Trip input for it to function properly. The low current requirement is specifically designed to minimize voltage drop, even over long cable runs, which is crucial in large installations where maintaining stable voltage is essential.

- The Trip input is designed for rapid response, with a trigger time of less than 5 milliseconds, and the output relays respond in under 1 millisecond. To ensure optimal performance, best wiring practices should be followed. It is recommended to use twisted-pair cables for the Trip input wiring to reduce noise interference. Additionally, it is important to avoid running Trip input cables alongside AC wiring, as this could lead to potential signal disruption or misoperation. Following these guidelines will help maintain the reliability and quick response of the Trip input system.

World of Controls has the most comprehensive collection of GE Mark VI components. Please contact WOC as soon as possible if you require any extra information.

Frequently Asked Questions

What is IS200TREAS4A?

It is a Emergency Trip Terminal Board developed by GE

What are the functions of jumpers JP1 and JP2 on the terminal board?

Jumpers JP1 and JP2 on the terminal board are used to configure the fanning of speed pickups among different sections of the PPROs (TMR sections). By properly setting these jumpers, users can determine how the passive speed pickups from the X section are distributed to the S and T section PPROs.

How does jumper JP1 affect the fanning of speed pickups?

Jumper JP1 determines whether the three passive speed pickups from the X section are fanned to the S and T section PPROs. By placing the jumper over the specified pin pairs, users can enable the fanning of these speed inputs to the other two TMR sections (S and T sections).

What is the purpose of jumper JP2 in the fanning of speed pickups?

Jumper JP2 is also involved in the fanning configuration of speed pickups. By setting JP2 correctly, users can ensure that the three passive speed pickups from the R section are appropriately distributed to the other two TMR sections (S and T sections).