World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200TDBTH8A - TMR Contact I/O Terminal Board is available in stock which ships the same day.

IS200TDBTH8A - TMR Contact I/O Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TDBTH8A - TMR Contact I/O Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200TDBTH8A

Manufacturer: General Electric

Series: Mark VIe

Product Type: TMR Contact I/O Terminal Board

Number of channels: 24

Input span: 4-20 mA

Technology: Surface Mount

Input Current: 24 V dc

Input filter: Hardware filter, 4 ms

Common Mode Voltage Range: ±5 V

AC Voltage Rejection: 12 V rms

Maximum Lead Resistance: 15Ω

Number of relay channels on one TDBT board: 12

Analog output current: 0-20 mA

Operating temperature: -30 to 65 °C

Max response time: 25 ms

Technology: Surface Mount

Size: 17.8 cm wide x 33.02 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

Manual: GEH-6721D

FUNCTIONAL DESCRIPTION:

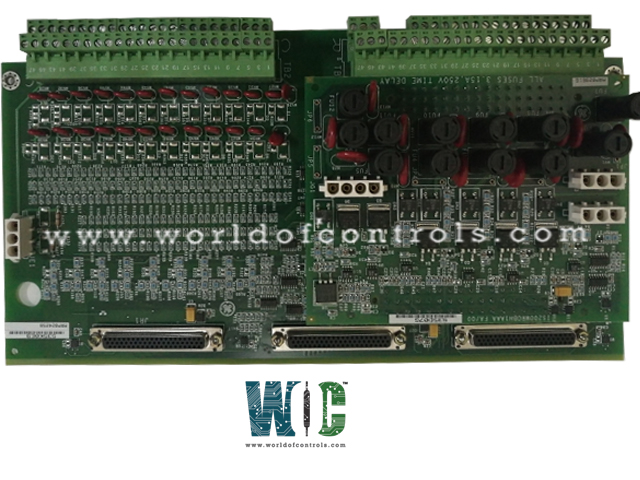

IS200TDBTH8A is a TMR Contact I/O Terminal Board manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. The TDBT board is a TMR contact input/output terminal board designed for DIN-rail or flat mounting. The TDBT board accepts 24 group isolated contact inputs that are supplied with a nominal 24, 48, or 125 V dc wetting voltage from an external source. The contact inputs have noise suppression to protect against surge and high-frequency noise. TDBT provides 12 form-C relay outputs and accepts an option card to expand relay functions. In Mark VIe systems, the PDIO I/O pack works with the TDBT. Three I/O packs plug into D-type connectors and communicate with the controllers over Ethernet. Three connection points for PDIO are provided. With dual controllers, the PDIO on TDBT connector JR1 would be networked to the R controller, JS1 PDIO to the S controller, and JT1 PDIO to both R and S controllers. With TMR controllers one network connection is provided to each PDIO leading to the respective controller. TDBT is not designed to operate correctly with a single PDIO I/O pack.

INSTALLATION:

The TDBT plus a plastic insulator mounts on a sheet metal carrier that then mounts on a DIN rail. Optionally the TDBT plus insulator mounts on a sheet metal assembly that then bolts in a cabinet. The connections are wired directly to two sets of 48 terminal blocks, typically using #18 AWG wires. The upper set of terminals, TB1, connects to the relay portion of the board and the lower set of terminals, TB2, connects to the contact input circuits. Screw assignments for the two sets of terminals are identical to those found on the SRLY relay board and the STCI contact input terminal board. Shields should be terminated on a separate bracket.

RELAY OUTPUTS:

If a relay option board is used, it plugs into TDBT connectors JW1 and JW2 and is held in place by the force of the connectors. The following table identifies the function of each relay terminal point grouped as TB1 as it relates to the presence of an option board. If external power is to be supplied it is wired to a connector provided on the option board.

CONTACT INPUTS:

Contact input connections are made to the 48 terminals on the lower portion of the terminal board, grouped as TB2. Contact wetting voltage is provided to the board through the JE1 3-pin Mate-n-lok connector on the lower portion of the board. The wetting voltage output terminals are all in parallel and fed from the positive voltage applied to JE1 pin 1. It is permissible to run a single wetting voltage lead from the board terminal to a group of remote contacts and then bring the individual contact wires back to the inputs. Negative or return wetting voltage is supplied by JE1 pin 3.

OPERATION:

The contact input function and on-board signal conditioning are the same as those on STCI, they are scaled for 24, 48, and 125 V dc wetting voltage. The input wetting voltage range is 16 to 32 V dc, 32 to 64 V dc, and 100 to 145 V dc respectively. The threshold voltage is 50% of the wetting voltage. The contact sensing circuits are shown in the I/O pack description. Contact input currents are resistance limited to 2.5 mA on the first 21 circuits, and 10 mA on circuits 22 through 24. The 24 V dc supply on TDBTH2 is currently limited to 0.5 A using polymer positive temperature coefficient fuses that can be reset. Filters reduce high-frequency noise and suppress surgeon input near the point of signal entry. The discrete input voltage signals go to the I/O processor which passes them through optical isolators, converts them to digital signals, and transfers them to the controller.

TDBT uses pluggable type terminals and has connectors JW1 and JW2 supporting option board connection. The relay portion of TDBT does not change between groups H2, H4, and H6, only the contact input circuits change. TDBT relays may be used at any specified ac or dc voltage without regard to the board group. Without an option board, the SOL terminal associated with each relay has no connection. TDBT is designed to support a current rating of 5 A and voltage clearance greater than is needed for 250 V ac on all customer screw and JW1 circuits. The relay contact rating is the limiting item for each application.

WOC has the largest stock of GE Distributed Control System Replacement Parts. We can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What are the key features of the TMR Contact I/O Terminal Board?

The board typically features multiple input and output channels, support for various communication protocols (such as Modbus, Ethernet/IP, etc.), robust construction suitable for industrial environments, and compatibility with different types of control systems.

How is the TMR Contact I/O Terminal Board installed and configured?

Installation usually involves mounting the board onto a DIN rail or a suitable surface within the control cabinet. Configuration involves setting up the input/output channels, assigning addresses, configuring communication protocols, and integrating it with the overall control system. Manufacturers often provide detailed installation and configuration guides to assist users.

Where can I purchase the TMR Contact I/O Terminal Board?

You can purchase the TMR Contact I/O Terminal Board directly from World of Controls, and they also provide comprehensive support services to assist you with your purchase, installation, configuration, and troubleshooting needs.