World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

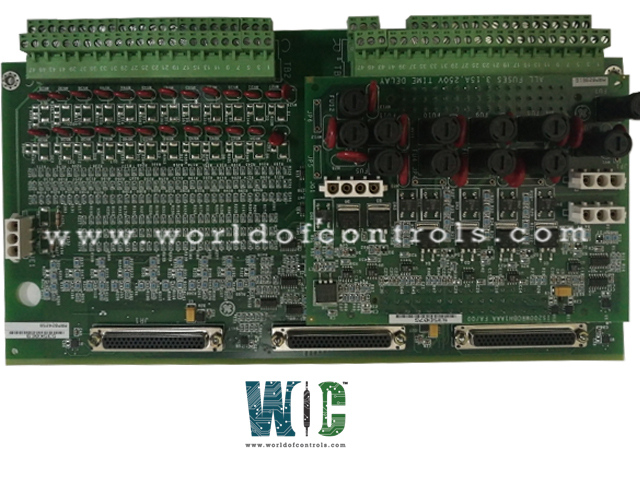

IS200TDBTH4A - TDBT Contact Input/Relay Output Terminal Board is available in stock which ships the same day.

IS200TDBTH4A - TDBT Contact Input/Relay Output Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TDBTH4A - TDBT Contact Input/Relay Output Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part No.: IS200TDBTH4A

Manufacturer: General Electric

Product Type: TDBT Contact Input/Relay Output Terminal Board

Series: Mark VIe

Number of Channels: 24

Wetting voltage: 24 V dc

Input current: Input current

Input filter Hardware filter: 4 ms

Description: I/O Terminal Board

AC input frequency: 480 Hz maximum

Operating Temperature: -30 to 65°C

Contact material: Silver cad-oxide

Number of relay channels on one TDBT board: 12

Max load current: Max load current

Technology: Surface-mount

Max response time: 25 ms

AC voltage rejection: 12 V rms

Availability: In Stock

Size: 17.8 cm wide x 33.02 cm

Country of Manufacture: United States (USA)

Manual: GEH-6721D

FUNCTIONAL DESCRIPTION:

IS200TDBTH4A is a TDBT Contact Input/Relay Output Terminal Board manufactured and designed by General Electric and is part of the Mark VIe Series used in GE Distributed turbine control systems. The TDBT board is a TMR contact input/output terminal board designed for DIN-rail or flat mounting. It supports 24 group-isolated contact inputs, powered by an external source with a nominal wetting voltage of 24, 48, or 125 V DC. These inputs feature built-in noise suppression to guard against surges and high-frequency interference. Additionally, the board offers 12 form-C relay outputs and supports an optional card to expand relay functionality.

In Mark VIe systems, the TDBT interfaces with PDIO I/O packs through three D-type connectors, enabling communication with controllers over Ethernet. For dual controller configurations, the PDIO connected to JR1 links to the R controller, JS1 to the S controller, and JT1 to both R and S controllers. In TMR systems, each PDIO connects to its corresponding controller. The TDBT board requires all three PDIO packs for proper operation and is not designed to function with only one.

INSTALLATION:

The TDBT board, along with a plastic insulator, is mounted on a sheet metal carrier that attaches to a DIN rail. Alternatively, it can be mounted on a sheet metal assembly that bolts directly into a cabinet. Wiring uses two sets of 48 terminal blocks, typically with #18 AWG wires. The upper terminal block, TB1, is used for relay connections, while the lower terminal block, TB2, handles contact input circuits. The terminal screw assignments are the same as those on the SRLY relay board and the STCI contact input board. Cable shields should be grounded using a separate bracket.

RELAY OUTPUTS:

When a relay option board is used with the TDBT, it connects to the main board through connectors JW1 and JW2. The option board is secured in position by the mechanical engagement of these connectors—no additional fasteners are required. This optional module enhances the relay functionality of the TDBT board, enabling additional configurations or isolations as required by the application.

Terminal block TB1, located on the upper section of the board, is associated with the relay outputs. The specific function of each terminal point within TB1 depends on whether the relay option board is installed. Without the option board, standard relay output connections are available directly on TB1. With the option board in place, the functions of these terminals may be modified or expanded, depending on the design of the relay enhancement.

OPERATION:

The contact input functionality and onboard signal conditioning of the TDBT board are equivalent to those of the STCI, configured for wetting voltages of 24, 48, and 125 V DC. The corresponding input wetting voltage ranges are 16–32 V DC, 32–64 V DC, and 100–145 V DC, with threshold voltages set at 50% of the wetting voltage. Detailed contact sensing circuit diagrams are included in the I/O pack documentation.

Input currents are limited by resistance to 2.5 mA for circuits 1–21 and 10 mA for circuits 22–24. The 24 V DC supply on the TDBTH2 is restricted to 0.5 A using resettable polymer PTC fuses. Filters positioned near the signal entry points mitigate high-frequency noise and surges. The discrete input voltage signals are processed by the I/O pack, which routes them through optical isolators for conversion to digital form before transmitting them to the controller.

WOC offers the largest inventory of replacement parts for GE Distributed Turbine Control Systems. In addition to supplying new and refurbished boards with warranty coverage, we also provide expert repair services for faulty components. Our dedicated team is available 24/7 to support all your OEM and automation needs. For inquiries about pricing and availability, please reach out to us via phone or email—our specialists are always ready to assist you.

What is the function of the TDBT terminal board?

The TDBT board serves as a TMR (Triple Modular Redundant) contact input and relay output terminal board. It is used in GE Mark VIe turbine control systems to process isolated contact inputs and provide reliable relay outputs.

What types of outputs are available on the TDBT?

The TDBT board provides 12 form-C (SPDT - Single Pole Double Throw) relay outputs, which are commonly used for switching applications in turbine control systems. Each relay output consists of a normally open (NO), normally closed (NC), and common (COM) contact, offering flexible configuration for control and monitoring purposes.

What wetting voltage levels are supported for contact inputs?

The TDBT board supports nominal wetting voltages of 24 VDC, 48 VDC, and 125 VDC, supplied from an external power source. These voltages are used to detect the open or closed status of field contacts. The contact input circuits are group-isolated and include built-in noise suppression features, such as surge protection and high-frequency filtering, to ensure reliable signal processing even in electrically noisy environments.