World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

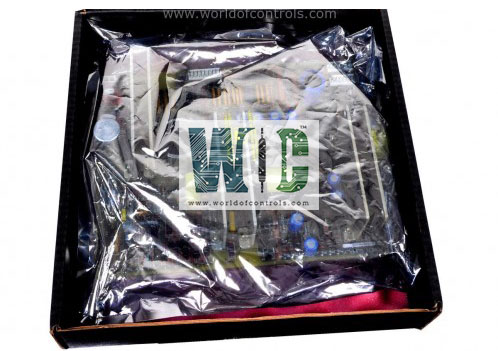

IS200TDBSH8A - Simplex Contact Input / Output Terminal Board is available in stock which ships the same day.

IS200TDBSH8A - Simplex Contact Input / Output Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TDBSH8A - Simplex Contact Input / Output Terminal Board, contact us and we will get back to you within 24 hours.

Part No.: IS200TDBSH8A

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Input filter Hardware filter, 4 ms

Size: 17.8 cm wide x 33.02 cm high

Temperature: -30 to + 65oC

Max response time on: 25 ms typical

Max response time off: 25 ms typical

Contact material: Silver cad-oxide

Technology: Surface-mount

Product Type: simplex contact input/output terminal board

Availability: In Stock

Series: Mark VIe

IS200TDBSH8A is a simplex contact input/output terminal board developed by GE. It is a part of the Mark VIe control system. Within Mark VIe systems, the PDIO I/O pack collaborates seamlessly with the board. This I/O pack is effortlessly integrated via a D-type connector, establishing communication with the controller through Ethernet. A singular connection point facilitates PDIO connectivity, offering the option for one or two network connections from the PDIO to the controllers.

The WOC team is always available to help you with your Mark VIe requirements. For more information, please contact WOC.

What is IS200TDBSH8A?

It is a simplex contact input / output terminal board developed by GE under the Mark VIe series.

How is the contact input wetting voltage monitored on the TDBS board?

The contact input wetting voltage is continuously monitored by the board. If the wetting voltage drops below 40 percent of the nominal voltage, a diagnostic alarm, or fault, is triggered and latched, indicating a potential issue with the input circuit.

How does the TDBS board provide diagnostic feedback to PDIO?

The board offers diagnostic feedback to the PDIO by monitoring an isolated set of contacts on each relay. This feedback mechanism allows the PDIO to accurately assess the state of each relay and detect any anomalies or faults.

What is the role of isolated voltage feedback when using WROB with TDBS?

When utilizing WROB with the TDBS, isolated voltage feedback is employed to detect the status of the six fuse pairs on the board. This feedback mechanism enhances diagnostic capabilities by providing real-time information about fuse status.

How is isolated voltage feedback utilized with WROF and WROG options on TDBS?

When employing WROF or WROG options with the TDBS board, isolated voltage feedback is utilized to monitor each fuse individually. If voltage is present and the fuse is open, a diagnostic alarm is generated, alerting users to potential issues with the fuse.

Can the diagnostic feature be disabled in PDIO configuration?

Yes, the diagnostic feature associated with isolated voltage feedback can be disabled in PDIO configuration if desired. This allows users to use the feedback circuit even when the fuse is removed, providing flexibility in diagnostic management.