World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200TBCIH3C - Contact Input Terminal Board is available in stock which ships the same day.

IS200TBCIH3C - Contact Input Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TBCIH3C - Contact Input Terminal Board, contact us and we will get back to you within 24 hours.

Part Number: IS200TBCIH3C

Manufacturer: General Electric

Series: Mark VIe

Product Type: Contact Input Terminal Board

Number of channels: 24

Power supply voltage: 28 V dc

Voltage Range: 14 to 32 V dc

Mounting: DIN-rail mounting

Technology: Surface mount

Operating temperature: -30 to 65 degrees Celsius

Size: 33.02 cm high x 17.8 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

Manual: GEH-6421M

IS200TBCIH3C is a Contact Input Terminal Board manufactured by General Electric. It is a part of Mark VIe Series used in GE Speedtronic Gas Turbine Control Systems. The Contact Input with Group Isolation (TBCI) terminal board is capable of receiving 24 dry contact inputs that are connected to two barrier-type terminal blocks. For contact excitation, DC power is supplied to the TBCI. Surge and high-frequency noise are protected by noise suppression circuitry in the contact inputs. Do not inadvertently connect the 240 V ac and dc voltages in 240 V ac applications. The peak voltage will exceed the MOV rating, causing the device to fail. Most ac supplies use a grounded neutral, and if an inadvertent connection is made between the 125 V dc and the ac voltage, the sum of the ac peak voltage and the 125 V dc is applied to MOVs connected between dc and ground. In 120 V ac applications, however, the MOV rating can withstand the peak voltage without failing.

WOC has the largest stock of GE Speedtronic Gas Turbine Control System Replacement Parts. We can also repair your faulty boards. WORLD OF CONTROLS can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs contact us.

What is IS200TBCIH3C?

It is a Contact Input Terminal Board manufactured by General Electric.

How to Check Price and Availability For this component?

Please Contact World of Controls FZE for sales at +1 609 385 1231 or Request a Quote.

What is the number of channels in the Board?

The component has 24 channels.

What is the power supply voltage required for the Terminal Board?

It requires a power supply voltage of 28 V dc.

What is the voltage range?

The voltage range for the Contact Input Terminal Board is 14 to 32 V dc.

How is the Terminal Board mounted?

It is mounted on a DIN-rail.

What is the technology used?

The Board uses surface mount technology.

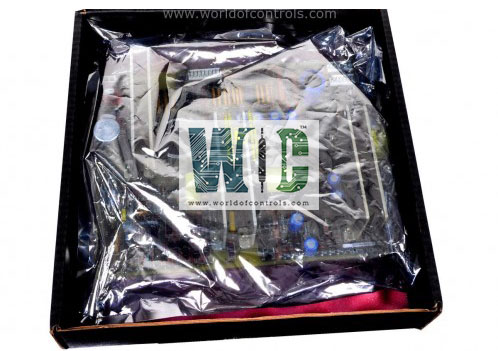

How are boards packaged for shipment from WOC?

Parts are placed in antistatic packets and securely packed in ESD boxes cushioned with ESD Foam designed to safeguard electrical components.