World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

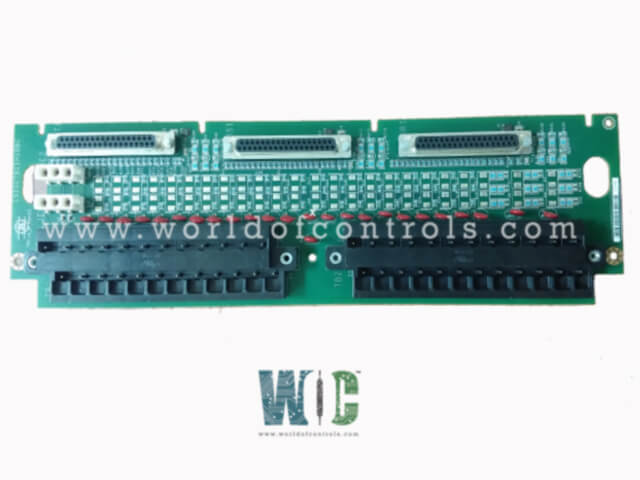

IS200TBCIH1CAA - Contact Input Terminal Board is available in stock which ships the same day.

IS200TBCIH1CAA - Contact Input Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TBCIH1CAA - Contact Input Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200TBCIH1CAA

Manufacturer: General Electric

Series: Mark VIe

Product Type: Contact Input Group Isolation Terminal Board

Number of Channels: 24

Input Current: 124 V dc

Power supply voltage: 28 V dc

Voltage Range: 14 to 32 V dc

LVDT excitation output: 3.2 ±0.2 kHz

Mounting: DIN-rail mounting

Technology: Surface mount

Operating temperature: -30 to 65°C

Size: 33.02 cm high x 10.16 cm

Repair: 3-7 Days

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

Manual: GEH-6721D

FUNCTIONAL DESCRIPTION:

IS200TBCIH1CAA is a Contact Input Group Isolation Terminal Board manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. The board provides 24 dry contact inputs, organized into electrically isolated groups to prevent fault propagation between inputs. Inputs are terminated on barrier-type terminal blocks and are energized via an external DC supply connected to the board. Each input includes noise suppression circuitry to filter transient surges, high-frequency interference, and electrical disturbances. When a contact closes, the board generates a conditioned digital signal for transmission to the control system. Group isolation ensures that faults, shorts, or noise in one input group do not affect other groups, maintaining signal integrity across all channels.

COMPATIBILITY:

The TBCI terminal board is fully compatible with the PDIA I/O pack and supports simplex, dual, and triple modular redundancy (TMR) configurations. Depending on the application, one, two, or three PDIA modules can be directly installed onto a single TBCI board, enabling flexible system architectures and redundancy schemes. For installations using the Mark VIe control system, the C version of the TBCI board is required to ensure proper mechanical alignment of connector JT1 with the I/O pack's mechanical support, guaranteeing a reliable connection and preventing misalignment that could affect signal integrity or system operation. This mechanical compatibility, combined with the board’s ability to accommodate multiple PDIA modules, allows the TBCI to function effectively in both standard and high-availability control configurations.

INSTALLATION:

Connect the wires for the 24 dry contact inputs directly to two I/O terminal blocks on the terminal board. These blocks are held down with two screws and can be unplugged from the board for maintenance. Each block has 24 terminals accepting up to #12 AWG wires. A shield terminal strip attached to chassis ground is located immediately to the left of each terminal block. In a simplex system, connect the TBCI to the PDIA I/O pack using connector JR1. In a TMR system, connect TBCI to the three PDIAs using connectors JR1, JS1, and JT1. The PDIAs plug into TBCI and attach to side-mounting brackets. One or two Ethernet cables plug into the I/O pack. Firmware may need to be downloaded. Connect TBCI to the contact excitation voltage source using plugs JE1 and JE2.

OPERATION:

Filters reduce high-frequency noise and suppress surge on each input near the point of signal entry. The dry contact inputs on TBCI_1C are powered from a floating 125 V dc (100-145 V dc) supply from the turbine control. The 125 V dc bus is current-limited in the power distribution module before feeding each contact input. The H2, H3, and H4 versions use lower voltages. The discrete input voltage signals pass to the PDIA I/O pack, which sends them through optical isolators providing group isolation and transfers the signals to the Mark VIe controller. The reference voltage in the isolation circuits sets a transition threshold that is equal to 50% of the applied floating power supply voltage.

The tracking is clamped to go no less than 13% of the nominal rated supply voltage to force all contacts to indicate open when voltage dips below this level. A pair of terminal points is provided for each input, with one point (screw) providing the positive DC source and the second point providing the return (input) to the board. The current loading is 2.5 mA per point for the first 21 inputs on each terminal board. The last three have a 10 mA load to support an interface with remote solid-state output electronics. Contact input circuitry is designed for NEMA Class G creepage and clearance.

WOC maintains the largest inventory of OEM replacement parts for GE Distributed Control Systems (DCS), offering new, unused components as well as professionally rebuilt and fully warranted boards. In addition, we provide expert repair services for faulty or damaged boards, restoring them to full operational capability. Our team of specialists is available 24/7 to support all OEM requirements, offering prompt technical guidance, system compatibility advice, and solutions for any automation need. For pricing, availability, or assistance with parts and repairs, contact our team via phone or email to ensure your systems continue to operate reliably and efficiently.

What is the primary function of the TBCI terminal board?

The TBCI board interfaces dry contact inputs to a control system. It conditions the inputs and outputs to clean digital signals. Group isolation ensures that faults or noise in one input group do not affect others.

How are the inputs organized on the board?

Inputs are divided into isolated groups and terminated on barrier-type terminal blocks. Grouping maintains electrical separation and simplifies wiring. This also facilitates maintenance and troubleshooting.

What is the purpose of group isolation in the TBCI?

Group isolation prevents faults, short circuits, or electrical noise in one group from affecting other inputs. It ensures signal integrity across all channels. Isolation is maintained by dedicated circuitry for each group.

How is DC excitation applied to the inputs?

DC excitation voltage is supplied externally to the TBCI board. This energizes the inputs and allows detection of open or closed contacts. A proper DC supply is essential for correct input operation.

What type of noise protection is provided for the inputs?

Each input includes built-in noise suppression circuitry. It filters transient voltage spikes, surges, and high-frequency interference. This prevents false triggering and maintains accurate signal detection.