World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

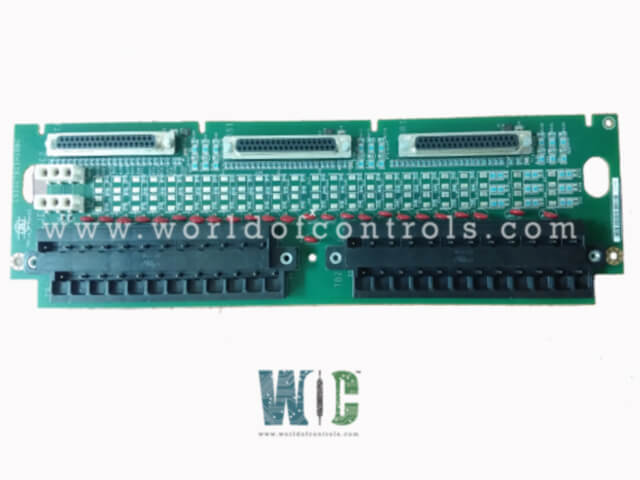

IS200TBCIH1BAB - Contact Input with Group Isolation Terminal Board is available in stock which ships the same day.

IS200TBCIH1BAB - Contact Input with Group Isolation Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TBCIH1BAB - Contact Input with Group Isolation Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200TBCIH1B

Manufacturer: General Electric

Series: Mark VIe

Product Type: Contact Input with Group Isolation Terminal Board

Number of channels: 24

Excitation voltage: 125 V dc

Input current: 10 mA

Power consumption: 20.6 W

Physical size: 33.02 cm high × 10.16 cm wide

Repair: 3-5 Days

Product of Origin: United States

Availability: In Stock

Manual: GEH-6721_Vol_II

FUNCTIOANL DESCRIPTION:

IS200TBCIH1BAB is a Contact Input with Group Isolation Terminal Board manufactured and designed by General Electric as part of the Mark VIe Series used in GE distributed control systems. The Contact Input with Group Isolation (TBCI) terminal board accepts 24 dry contact inputs wired to two barrier-type terminal blocks. For contact excitation, DC power is wired to TBCI. The contact inputs have noise suppression circuitry to protect against surges and high-frequency noise. The PDIA I/O packets in the Mark VIe system plug into the TBCI. A range of system configurations is supported by one, two, or three PDIA packs. For the connector JT1 to be correctly mechanically aligned with the mechanical support of the I/O pack in Mark VIe, this board must be in the C version.

COMPATIBILITY:

The TBCI works with the PDIA I/O pack and supports simplex, dual, and TMR applications. One, two, or three PDIAS can be plugged directly into the TBCI. The Mark Vle control requires the C version of this board for correct mechanical alignment of connector JTI to the I/O pack mechanical support.

INSTALLATION:

Connect the wires for the 24 dry contact inputs directly to two I/O terminal blocks on the terminal board. These blocks are held down with two screws and can be unplugged from the board for maintenance. Each block has 24 terminals accepting up to #12 AWG wires. A shield terminal strip attached to chassis ground is located immediately to the left of each terminal block. In a simplex system, connect the TBCI to the PDIA I/O pack using connector JR1. In a TMR system, connect TBCI to the three PDIAS using connectors JR1, JS1, and JT1. The PDIAS plug into TBCI and attach to side-mounting brackets. One or two Ethernet cables plug into the I/O pack. Firmware may need to be downloaded. Connect TBCI to the contact excitation voltage source using plugs JE1 and JE2.

OPERATION:

Filters reduce high-frequency noise and suppress surge on each input near the point of signal entry. The dry contact inputs on TBCI_IC are powered from a floating 125 V dc (100-145 V dc) supply from the turbine control. The 125 V bus is current-limited in the power distribution module prior to feeding each contact input. The H2, H3, and H4 versions use lower voltages (refer to the section, Specifications).

The discrete input voltage signals pass to the PDIA I/O pack, which sends them through optical isolators providing group isolation and transfers the signals to the Mark VIe controller. The reference voltage in the isolation circuits sets a transition threshold that is equal to 50% of the applied floating power supply voltage. The tracking is clamped to go no less than 13% of the nominal rated supply voltage to force all contacts to indicate open when voltage dips below this level.

A pair of terminal points is provided for each input, with one point (screw) providing the positive de source and the second point providing the return (input) to the board. The current loading is 2.5 mA per point for the first 21 inputs on each terminal board. The last three have a 10 mA load to support an interface with remote solid-state output electronics. Contact input circuitry is designed for NEMA Class G creepage and clearance.

WOC maintains the largest inventory of GE Distributed Control System OEM replacement parts, ensuring fast and reliable access to the components you need. In addition to supplying brand-new, unused, and rebuilt parts, all backed by a comprehensive warranty, we also specialize in repairing faulty boards to restore your systems to peak performance. Our team of highly skilled experts is available 24/7 to provide technical support, guidance, and solutions for all your automation and control requirements. Whether you need parts, repairs, or expert advice, WOC is committed to delivering prompt, reliable, and professional service. Simply contact us by phone or email for pricing, availability, or assistance.

What is a group isolation terminal board, and why is it used?

A group isolation terminal board divides the 24 contact input channels into electrically isolated groups, typically 4–6 channels per group. Each group is isolated from the others to prevent faults, voltage spikes, or short circuits in one group from affecting the rest of the system.

How many input channels can be isolated per group?

The 24 channels are usually split into several isolated groups, such as 4 groups of 6 channels each, depending on the module configuration. Each group operates independently, allowing technicians to test or troubleshoot one group without impacting the others.

What types of voltage inputs are supported?

The module supports multiple nominal input voltages: 24 V dc, 48 V dc, and 125 V dc. Channels can be floating or grounded, depending on the group configuration. This flexibility allows integration into a variety of control systems and industrial environments.