World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200TBCAH2A - RTD Input Termination Module is available in stock which ships the same day.

IS200TBCAH2A - RTD Input Termination Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200TBCAH2A - RTD Input Termination Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

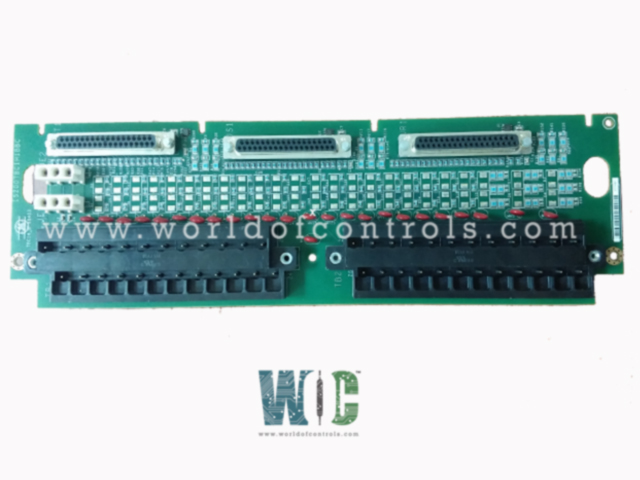

Part Number: IS200TBCAH2A

Manufacturer: General Electric

Series: Mark VIeS

Product Type: RTD Input Termination Module

Number of Channels: 6

Input Compatibility: Pt100

Supply Voltage: 24 V DC

Analog output current: 0-20 mA

Output Signal: 4-20 mA, RS485, Modbus

Operating Temperature: -40°C to +85°C

Storage Temperature: -55°C to +105°C

Ingress Protection (IP) Rating: IP20, IP65

Size: 15.9 cm high x 17.8 cm wide

Frequency: 50 or 60 Hz

Repair: 3-7 Days

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

Manual: GEH-6153

FUNCTIONAL DESCRIPTION:

IS200TBCAH2A is an RTD Input Termination Module manufactured and designed by General Electric as part of the Mark VIeS Series used in GE Distributed Turbine Control Systems. It is a device used to interface and terminate the connections of RTDs in a system. An RTD (Resistance Temperature Detector) is a type of temperature sensor that operates on the principle that the electrical resistance of certain materials changes with temperature. It provides accurate and reliable temperature measurements, making it widely used in various industries. The Termination Module RTD and 4ñ20 mA Input (TBCB) are in location seven of the R5 core. RTD and mA input signals are landed on the TBCB terminal board. Eight of the 4 -20 mA input signals have the option to be configured using hardware jumpers to be 0 -1 mA input signals. The signals connected to the TBCB terminal board are written to the TCCB board in the R5 core.

KEY FEATURES AND FUNCTIONS OF RTD TERMINATION MODULE:

Connection point: It provides a secure and standardized connection point for the RTD sensors. RTDs typically have two or three wire configurations, and the termination module ensures proper connections for accurate temperature readings.

Termination of wires: The module allows for the proper termination of RTD wires to prevent signal degradation and interference.

Signal conditioning: In some cases, the termination module may include signal conditioning circuitry to amplify and filter the RTD's output signal. This helps improve the accuracy and reliability of the temperature measurement.

Protection: The module may include protection mechanisms like surge protection or current limiting to safeguard the RTD and connected instrumentation from potential electrical issues.

Mounting and installation: The module typically comes with a convenient mounting arrangement, facilitating easy installation in control panels or junction boxes.

WHY PURCHASE IS210DSVOH1B FROM WOC?

WOC is a trusted global supplier known for its extensive inventory of genuine GE Distributed Turbine Control System parts, ensuring fast availability when operations are at stake. Our team of certified engineers provides quick and reliable repairs, typically completed within 3-7 days, while maintaining strict OEM-level quality standards across all components. We offer competitive pricing on new, unused, surplus, and refurbished parts, along with comprehensive warranties for added peace of mind. With worldwide shipping capabilities and 24/7 technical support, WOC delivers the expertise, reliability, and responsiveness that industries depend on to keep their systems running smoothly.

What is the primary function of an RTD Input Termination Module?

An RTD Input Termination Module provides a secure interface between RTD temperature sensors and the control system. It ensures proper signal termination, minimizes noise, and maintains measurement accuracy. The module transfers conditioned temperature signals to the controller for processing and monitoring.

Which RTD sensor types are supported by the IS200TBCAH2A module?

The IS200TBCAH2A is designed to support Pt100 RTD sensors, which are widely used in turbine and industrial temperature measurement. Pt100 sensors provide high accuracy and long-term stability. The module supports standard RTD wiring configurations to ensure reliable readings.

How many RTD channels are available on this termination module?

The module supports six independent RTD input channels, allowing multiple temperature points to be monitored simultaneously. Each channel is electrically isolated to prevent cross-channel interference. This makes it suitable for multi-zone or multi-component temperature monitoring.

Does the RTD termination module provide signal conditioning?

Yes, the module is designed to maintain signal integrity by reducing electrical noise and ensuring stable signal transmission. Proper termination helps prevent resistance errors and signal distortion. This improves the accuracy and reliability of temperature data sent to the control system.

What communication methods are supported by this module?

The IS200TBCAH2A supports industrial communication via RS-485 using the Modbus protocol. This enables reliable data exchange between the termination module and the control processor. Modbus support allows seamless integration into existing GE Mark VIeS systems.