World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200SRTDH1ABB - Simplex RTD Board is available in stock which ships the same day.

IS200SRTDH1ABB - Simplex RTD Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200SRTDH1ABB - Simplex RTD Board, contact us and we will get back to you within 24 hours.

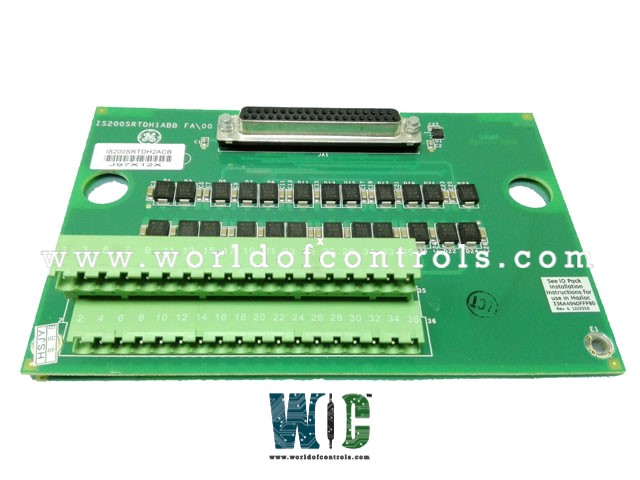

Part No.: IS200SRTDH1ABB

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature Operating: -30 to 65 o C

Number of channels: 8

Span: 0.3532 to 4.054 V

Product Type: Simplex RTD Board

Availability: In Stock

Series: Mark VIe

IS200SRTDH1ABB is an Simplex RTD Board developed by GE. It is a part of Mark VIe excitation system. The board represents a compact and efficient solution for integrating Resistance Temperature Detector (RTD) inputs within a control system setup. The board is designed to be compact, facilitating easy integration into control system setups. It is versatile, allowing for mounting on either a DIN-rail or a flat surface, providing flexibility to suit different installation requirements and environments.

The WOC team is always available to help you with your Mark VIe requirements. For more information, please contact WOC.

What is IS200SRTDH1ABB?

It is an Simplex RTD Board developed by GE under the Mark VIe series.

What happens if hardware limits for an RTD input are exceeded?

If hardware limits are exceeded for an input, a logic signal is triggered, and the input is no longer scanned. Additionally, if any of the inputs exceed their hardware limits, it generates a composite diagnostic alarm (L3DIAG PRTD), referring to the entire board.

How are system limit checks configured for RTD inputs?

System limit checks for inputs are based on configurable high and low levels. These limits can be adjusted to generate alarms and configured for enable/disable, as well as latching/non-latching. The RESET SYS signal resets out-of-limit signals.

How is the resistance of each RTD checked?

The resistance of each RTD is continuously monitored and compared with the correct value. If the resistance is too high or too low, a fault is generated, indicating a potential issue with the RTD sensor.

What information is stored in the ID device for each connector?

Each connector on the board has its own ID device containing essential information such as the terminal board serial number, board type, revision number, and the connector's location. This information is coded into a read-only chip and is interrogated by the I/O processor board. Any mismatch encountered during interrogation results in a hardware incompatibility fault.

How are diagnostic signals managed and reset?

Diagnostic signals can be individually latched and then reset using the RESET DIA signal. This allows for efficient management and troubleshooting of diagnostic alarms, ensuring system integrity and reliability.