World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

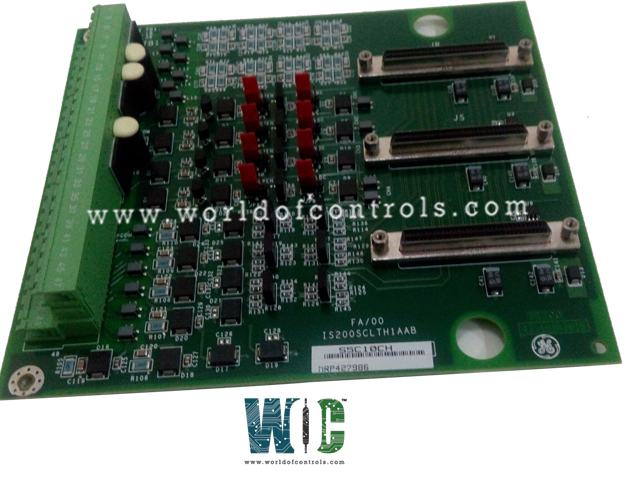

IS200SCLTH1AAB - Core Analog Terminal Board is available in stock which ships the same day.

IS200SCLTH1AAB - Core Analog Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200SCLTH1AAB - Core Analog Terminal Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200SCLTH1AAB

Manufacturer: General Electric

Series: Mark VIe

Product Type: Core Analog Terminal Board

Number of Channels: 8

Interface: With SCLS and field wires

Common Mode Voltage Range: ±5 V

Fault detection: Incorrect ID chip

Power supply voltage: 28 V DC

Size: 6.25 inch x 7 .00 inch

Technology: Surface Mount

Thermocouple types: E, J, K, S, T

Span: -16.0 mV to 63.0 mV

Operating temperature: -30 to 65°C

Repair: 3-7 days

Availability: In Stock

Country of Origin: United States

Manual: GEH-6721_Vol_II V

FUNCTIONAL DESCRIPTION:

IS200SCLTH1AAB is a Core Analog Terminal Board manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Gas Turbine Control Systems. The Core Analog (SCLT) Terminal Board is a high-performance interface designed to support analog signal processing for one or up to three PCLA modules within turbine control systems. It accommodates multiple input types, including eight thermocouple inputs for temperature monitoring, four analog voltage or current inputs for sensors, and six 4-20 mA analog output channels used to drive field actuators. To ensure stable and isolated signal transmission, the board includes a dedicated 24 V DC power supply specifically for the 4-20 mA input loops. This setup enables accurate signal acquisition and improves reliability in critical control applications.

The SCLT board offers robust field wiring capabilities through 48 pluggable Euro-style terminal blocks, simplifying installation and maintenance. Its compatibility with redundant PCLA module configurations allows for 2-out-of-3 voting logic, enhancing system reliability and fault tolerance. Designed for seamless integration into GE turbine control architectures such as Mark VI and Mark VIe, the SCLT board ensures high-resolution data handling, consistent analog signal integrity, and improved diagnostics for efficient system performance.

INSTALLATION:

An I/O cable shield terminal is conveniently located adjacent to the terminal blocks on the SCLT board, providing a dedicated grounding point to ensure effective shielding and noise reduction for all field wiring. Proper shielding is critical in industrial environments to minimize electromagnetic interference (EMI) and maintain signal integrity, especially in analog signal transmission.

The field device I/O connections are facilitated through Euro-style box-type terminal blocks on both the SCLS and SCLT boards, designed for secure, modular, and easy wiring. Specifically, the SCLS board features 72 terminal blocks to accommodate a larger number of field conductors, while the SCLT board provides 48 terminal blocks, balancing compactness with sufficient connectivity for analog signals.

Both the SCLS and SCLT terminal blocks accept conductors with specific electrical and mechanical characteristics to ensure reliable connections and optimal performance. These conductors typically include copper wires with insulation rated for the system voltage, and they must conform to recommended wire gauge sizes to fit securely into the terminal blocks without compromising contact quality. The terminal design supports pluggable connections, which simplifies field installation and future maintenance by allowing easy removal and replacement of wiring harnesses without disturbing the rest of the system.

OPERATION:

The SCLT terminal board is engineered to efficiently fan out input signals to one or more PCLA modules, ensuring seamless signal distribution across redundant control channels. This signal fanning is achieved through the use of high-reliability passive circuits, such as resistive networks and diode isolation, which maintain signal integrity while providing fault tolerance critical in safety and redundancy applications. These passive components ensure that signals are reliably shared without introducing active points of failure, thereby enhancing overall system robustness.

Power for the SCLT board is supplied by the connected PCLA modules via a 28 V DC input line. To achieve redundancy and uninterrupted operation, the power supplies from all PCLA modules are combined using a Diode-OR configuration. This approach allows multiple power inputs to feed the 24 V DC outputs without backfeeding or interference between supplies, effectively creating a seamless redundant power source for the board. Each 24 V output on the SCLT is individually regulated through dedicated voltage regulators, which are equipped with thermal shutdown features. This built-in thermal protection safeguards each branch circuit against overloads or overheating, preventing damage to the board and connected devices.

For field wiring and system interfacing, the SCLT terminal board provides customer-accessible terminals as well as robust 68-pin connectors to interface with the SCLS terminal board via dedicated cabling. The SCLT features 48 pluggable Euro-style box-type terminal blocks, which serve as the primary connection points for field wiring. These modular terminal blocks facilitate easy installation, secure connections, and quick maintenance or replacement without disrupting the entire wiring system.

ANALOG VOLTAGE OR CURRENT INPUTS:

SCLT can accommodate four simplex / printed analog voltage or current inputs. They can be located up to 300 m (984 ft) from the turbine control cabinet with a maximum two-way cable resistance of 15 Ω. Connect the input and output wires directly to two I/O terminal blocks mounted on the terminal board. Each block is held down with two screws. A shield terminal attachment point is located adjacent to each terminal block. SCLT can accommodate the following analog I/O types:

WOC proudly maintains the largest inventory of GE Distributed Gas Turbine Control System replacement parts available in the market. Whether you need brand-new components or reliable rebuilt units, we stock a comprehensive range of parts to ensure your turbine control systems remain operational with minimal downtime. In addition to supplying unused and refurbished parts—each backed by a solid warranty for your peace of mind—we also offer expert repair services for faulty control boards to extend the life of your existing equipment.

Our dedicated team of highly skilled professionals is available 24/7 to provide prompt and knowledgeable support tailored to your Original Equipment Manufacturer (OEM) requirements. From troubleshooting and technical assistance to parts selection and system upgrades, we are committed to delivering outstanding customer service and solutions that keep your operations running smoothly. For detailed pricing, parts availability, or to discuss your specific repair and automation needs, please do not hesitate to contact our expert team via phone or email. At WOC, your operational success is our priority.

What types of signals does the SCLT terminal board support?

The SCLT terminal board supports a variety of analog signals essential for turbine control systems. It includes eight thermocouple inputs, which allow direct connection of temperature sensors for precise thermal monitoring. Additionally, it accepts four analog voltage or current inputs that can interface with various field sensors measuring parameters like pressure or flow. For control outputs, the board provides six 4-20 mA analog channels used to drive actuators or control devices such as I/P converters, enabling precise process control.

How does the SCLT ensure reliability in redundant systems?

To maintain high reliability, especially in safety-critical applications, the SCLT uses passive signal-fanning circuits to distribute inputs to one or up to three PCLA modules. This redundancy enables 2-out-of-3 voting logic, allowing the system to tolerate faults while continuing operation. The power inputs from multiple PCLA modules are combined through a diode-OR configuration, ensuring seamless redundant power supply without backfeed or interference. These design elements help maintain continuous system availability and protect against single-point failures.

What type of power supply does the SCLT terminal board require?

The SCLT board receives a 28 V DC power supply from the connected PCLA modules. This voltage is internally regulated to provide a dedicated and stable 24 V DC output used to power all 4-20 mA input loops. Each 24 V output channel features an individual voltage regulator equipped with thermal shutdown protection, which safeguards the system against overloads and prevents potential damage by shutting down overheated circuits. This design ensures robust, clean power delivery, critical for accurate analog signal processing.