World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

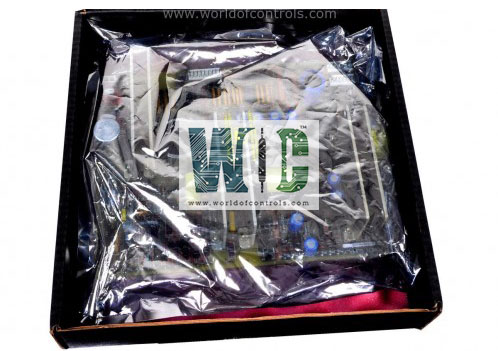

IS200PTBAG2A - Terminal board is available in stock which ships the same day.

IS200PTBAG2A - Terminal board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200PTBAG2A - Terminal board, contact us and we will get back to you within 24 hours.

Part No.: IS200PTBAG2A

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature Operating: 0 to 60 oC

Technology: Surface-mount

Product Type: Terminal board

Availability: In Stock

Series: Mark VIe

IS200PTBAG2A is a terminal board developed by GE. It is a part of Mark VIe series. This terminal board provides multiple connection points, facilitating the integration of various sensors and actuators required for turbine control and BoP equipment. As part of the system, the terminal board is designed to seamlessly integrate with other components of the Mark VIe control system, ensuring cohesive operation and communication.

The WOC team is always available to help you with your Mark VIe requirements. For more information, please contact WOC.

What is IS200PTBAG2A?

It is a Terminal board developed by GE under the Mark VIe series.

What is the configuration of S-type terminal boards?

S-type boards support one I/O pack for simplex and dual redundant systems and are half the size of T-type boards.

What are the mounting options for S-type terminal boards?

S-type terminal boards are standard base mounted but can also be DIN-rail mounted.

What types of terminal blocks are available for S-type boards?

S-type boards come in two versions- one with fixed Euro-style box type terminal blocks that are not removable, and another with removable box type terminal blocks.