World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

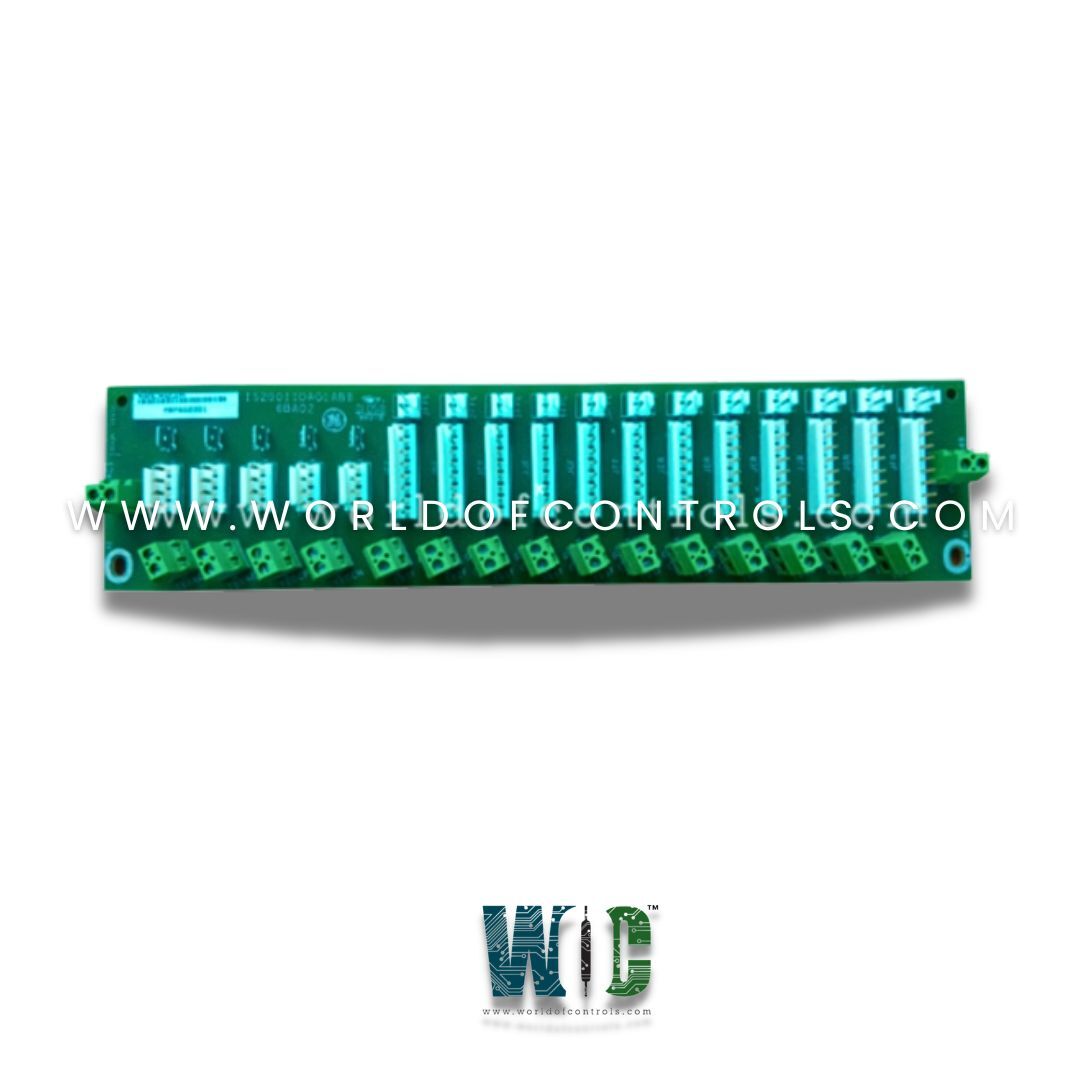

IS200IIDAG1ABB - DC Direct Current Innovation Board is available in stock which ships the same day.

IS200IIDAG1ABB - DC Direct Current Innovation Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200IIDAG1ABB - DC Direct Current Innovation Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS200IIDAG1ABB

Manufacturer: General Electric

Series: EX2100

Product Type: DC Direct Current Innovation Board

Rated Working Voltage: 48 V DC

Maximum Input Load Current: 63 A

Number of Input Channels: 24

Power Supply Voltage: 28 V DC

Technology: Surface Mount

Output Branches: 10 branches

Operating Temperature: �30 to 65 �C

Size: 33.02 cm (H) � 17.8 cm (W)

Repair Time: 3�7 Days

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

IS200IIDAG1ABB is a Direct Current Innovation Board manufactured and designed by General Electric as part of the EX2100 Series used in GE Excitation Control Systems. The Direct Current (DC) Innovation Board is an advanced interface and control module engineered to efficiently manage and regulate DC electrical systems in industrial and specialized applications. Its primary role is to continuously monitor voltage levels, current flow, and load distribution across connected DC circuits to ensure stable operation and optimized energy utilization. Equipped with intelligent features such as programmable logic, real-time data analytics, and compatibility with renewable energy and storage systems, the board enables next-generation energy management and control capabilities. Key features include:

For connectivity, the DC Innovation Board supports multiple industrial communication protocols such as CANopen, Modbus, EtherCAT, and RS-485, providing broad compatibility for system integration. It offers multiple digital and analog I/O channels for interfacing with sensors and peripheral equipment. Additionally, Pulse Width Modulation (PWM) technology enables precise motor control, delivering smooth speed variation and accurate torque management, while real-time feedback from encoders and tachometers ensures superior motor performance and reliability.

INSTALLATION:

The DC Innovation Board should be installed within a control cabinet or suitable electrical enclosure to ensure protection and reliability. Depending on the model, it supports both DIN rail and panel mounting configurations. Clearly labeled terminal blocks are provided for power input, load monitoring, and communication interfaces, allowing for organized and secure wiring. Installation must follow all applicable electrical safety standards, and all wiring should be performed only when the power supply is disconnected to avoid electrical hazards.

To maintain optimal performance, proper cable routing, grounding, and shielding of analog lines are essential to minimize electromagnetic interference (EMI) and ensure accurate signal transmission. The board is engineered to operate effectively within industrial temperature and humidity ranges, making it suitable for demanding environments where space efficiency and noise immunity are crucial.

OPERATION:

The DC Innovation Board provides continuous, real-time monitoring of DC voltage and current across all connected power sources and loads. Incoming signals are processed through integrated signal conditioning circuits for accurate measurement and reliability. The processed data is then communicated to external control or monitoring systems using industry-standard protocols such as Modbus RTU and CANopen.

Equipped with embedded control logic, the board performs essential functions such as voltage regulation, current limiting, undervoltage protection, and fault isolation to maintain stable and efficient system operation. It delivers reliable feedback and precise control outputs, enabling both standalone functionality and seamless integration within complex energy management or automation frameworks. The board�s architecture supports high-speed data acquisition, accurate fault detection, and synchronized control across interconnected subsystems for optimal performance and system reliability.

COMPATIBILITY:

The DC Innovation Board is compatible with a wide range of DC systems, including solar photovoltaic arrays, battery storage modules, DC motor drives, industrial UPS systems, and telecom power plants. It supports standard industrial voltages such as 12V, 24V, 48V, and higher ranges up to 600VDC, depending on model configuration. Communication with supervisory systems is enabled via industry-standard protocols like Modbus RTU, CAN, and optionally Ethernet/IP, allowing seamless integration with equipment from leading manufacturers such as Siemens, Schneider, GE, and Rockwell Automation. The board complies with CE and RoHS standards, ensuring safe operation and regulatory conformity in global industrial applications.

WOC maintains the largest inventory of OEM replacement parts for GE Excitation and Turbine Control Systems, offering fast access to genuine components as well as expert repair and refurbishment services for faulty boards. We provide both unused and professionally rebuilt units, each backed by a warranty to ensure reliability and performance. Our experienced team is available 24/7 to support all your OEM part requirements and automation challenges, delivering prompt guidance, technical assistance, and solutions to minimize downtime. For pricing, availability, or repair support, contact us via phone or email for professional, responsive service.

What is the IS200IIDAG1ABB?

The IS200IIDAG1ABB is a Direct Current (DC) Innovation Board used in GE Mark VI and IS200 turbine control systems. It manages DC circuits and provides monitoring and control functions within turbine control racks. The board is designed for industrial power generation applications, ensuring reliable and precise operation.

What types of motors can the DC Innovation Board control?

The DC Innovation Board can control standard DC motors, including both brushed and brushless types. It is compatible with permanent magnet (PM) motors, stepper motors, and other DC motor technologies used in industrial automation.

What communication protocols are supported?

The board supports industrial communication protocols such as Modbus RTU (via RS-485) and CANopen, with optional support for Ethernet/IP or Modbus TCP depending on the configuration. These protocols allow seamless integration with modern control and monitoring systems.

What voltage levels does the board support?

Depending on the specific model, the board typically supports standard industrial DC voltage ranges including 12 V DC, 24 V DC, 48 V DC, and up to 600 V DC. Always refer to the official datasheet for the exact supported voltage range.