World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS200EDFFH2A - DC Fanned Feedback Board is available in stock which ships the same day.

IS200EDFFH2A - DC Fanned Feedback Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200EDFFH2A - DC Fanned Feedback Board, contact us and we will get back to you within 24 hours.

Part No.: IS200EDFFH2A

Manufacturer: General Electric

Product Type: DC Fanned Feedback Board

Group Variation: H2, Dual System

Number of Channels: 13

Description: I/O Terminal Board

Ac input frequency: 480 Hz maximum

Ambient temperature: 0 to 40°C

Functionality: Field Current and Voltage Feedback

Number of Selector Settings: 8

Fiber-Optic Link: Voltage Isolation between EAUX and EDFF Boards

High-Noise Immunity: Supported by Fiber-Optic Link

Control Sections: Up to Three Redundant Control Sections

Operating System: Dual System

Series: EX2100e

Repair: 3-5 Days

Availability: In Stock

Country of Manufacture: United States (USA)

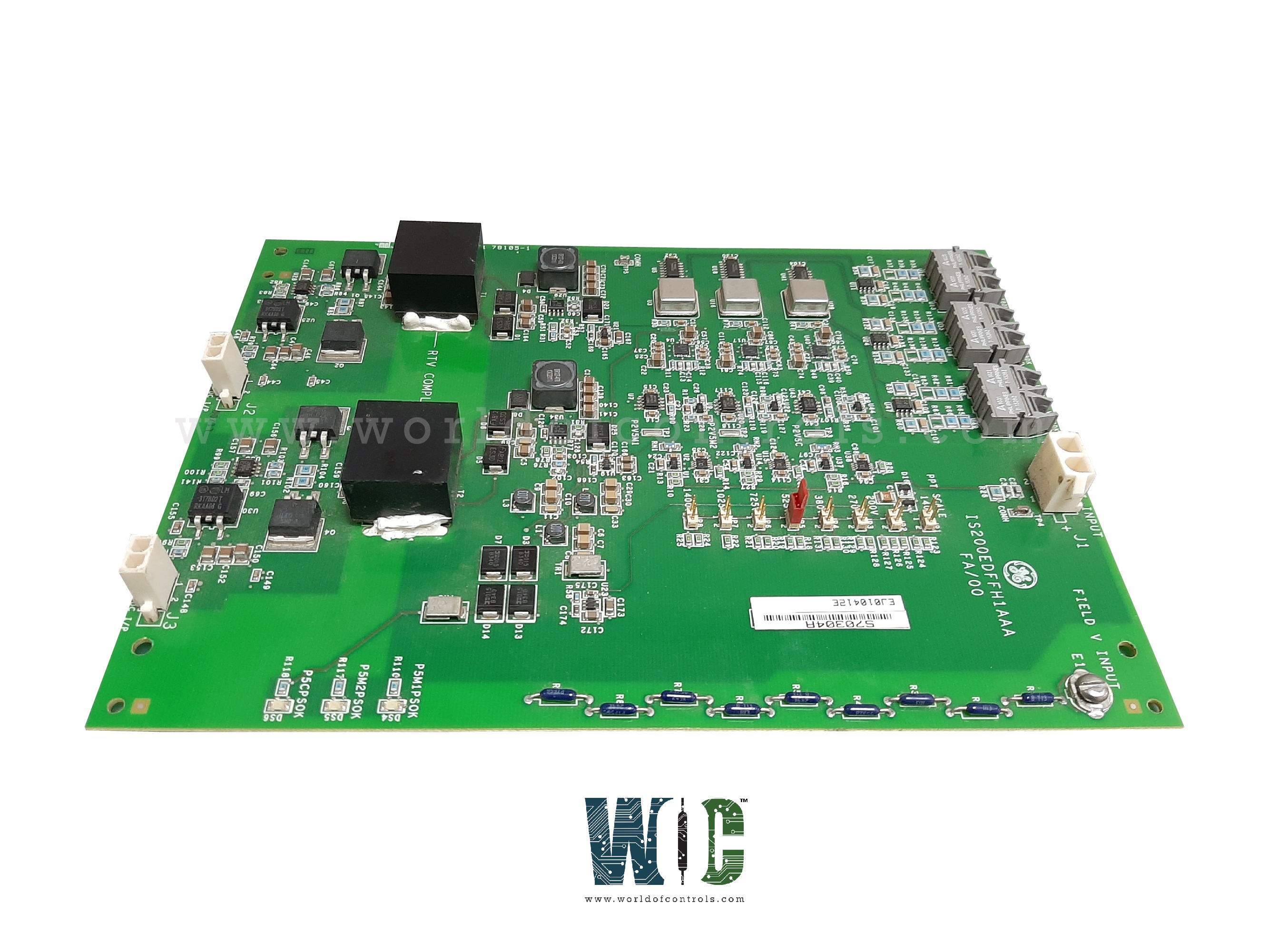

IS200EDFFH2A is a DC fanned feedback board developed by GE. It is a part of EX2100e excitation system. The component is characterized by its utilization of a dual system configuration, which enhances its operational performance and redundancy. For seamless operation, the board necessitates the presence of a fiber-optic link. This link serves the essential purpose of establishing voltage isolation between the EAUX and EDFF boards. This isolation not only ensures safe operations but also contributes significantly to noise immunity. Within the model, there exist three distinct groups, each tailored to different system requirements. In the case of the H2 group, to which the component belongs, the model functions within a dual system framework. This design choice augments its capabilities and operational resilience.

Tailored Adaptability: The board boasts eight selector settings designed to scale bridge voltages precisely according to the unique requirements of the bridge application. This adaptability ensures that the board can effectively accommodate a wide range of operational scenarios, providing accurate and appropriately scaled bridge voltage measurements.

Shunt-Based Precision: A key feature of this board is its ability to measure field currents. This capability is achieved through the integration of a shunt within the direct current (dc) field circuit. Utilizing this shunt-based approach, the board can precisely monitor field currents, significantly contributing to the overall efficiency and stability of the control system.

Enhanced Electrical Integrity: The integration of a fiber-optic link between the EUAX and EDFF boards serves multiple critical purposes. Firstly, it provides essential voltage isolation between these two boards, safeguarding against potential voltage fluctuations or imbalances that could affect their performance. Additionally, the fiber-optic link substantially enhances noise immunity, ensuring that external interference or electrical noise doesn't compromise the accuracy and reliability of the board's measurements.

Versatile Feedback Mechanisms: Central to the EDFF model are two V-F converter circuits. These circuits are strategically employed for field current and field voltage feedback mechanisms. This dual configuration significantly enhances the board's versatility and its ability to cater to various control scenarios. The V-F converter circuits play a pivotal role in transforming voltage signals into frequency outputs, facilitating efficient feedback loops within the broader control system architecture.

Exceptional Flexibility: The board exhibits remarkable flexibility by accommodating up to three redundant control sections. This design feature ensures a robust and reliable control system by providing backup mechanisms in case of component failures. The board's capacity to manage multiple control sections with redundancy further enhances the overall system's resilience and operational stability.

The necessity of a fiber-optic link for the proper functioning of the board cannot be overstated. This link plays a pivotal role in ensuring the board operates as intended, and its importance extends to various aspects of its performance and safety. Here, we will delve into the reasons behind this requirement and how the fiber-optic link benefits the system:

The primary purpose of the fiber-optic link is to establish voltage isolation between the EAUX and EDFF boards. Voltage isolation is paramount in applications where electrical safety is a concern. It serves as a barrier that prevents direct electrical connections between different components of the system. This isolation is crucial for protecting both the board and the personnel operating or maintaining the equipment.

The voltage isolation achieved through the fiber-optic link enhances the safety of the board and the entire system. It eliminates the risk of electrical shocks, short circuits, or other electrical hazards that could arise in the absence of isolation. This is especially important in industrial and high-voltage environments where personnel safety is a top priority.

Another critical advantage of the fiber-optic link is its ability to improve noise immunity. Electrical systems can be susceptible to electromagnetic interference (EMI) and radio frequency interference (RFI), which can introduce unwanted signals and disrupt the proper functioning of sensitive equipment. By using fiber optics, which are immune to these interference sources, the system's overall noise immunity is significantly enhanced.

In addition to voltage isolation and noise immunity, the fiber-optic link ensures the integrity of data transmission between the EAUX and EDFF boards. Fiber optics transmit data via light signals, which are immune to electromagnetic interference and can transmit data over long distances without signal degradation. This reliability is essential in applications where accurate data transfer is critical.

Fiber-optic links are capable of transmitting data over long distances without significant signal loss. This capability is advantageous in scenarios where the EAUX and EDFF boards are physically separated by considerable distances, such as in large industrial facilities or remote installations.

Fiber-optic cables are inherently resistant to environmental factors like moisture, chemicals, and temperature fluctuations. This robustness makes them suitable for a wide range of operating conditions, from harsh industrial environments to outdoor installations.

Incorporating a fiber-optic link into the board's design ensures that the system is prepared for future upgrades and expansions. Fiber-optic technology is well-established and continuously evolving, providing a reliable foundation for long-term system reliability and adaptability.

The model under consideration boasts a range of impressive measurement capabilities, with one of the most notable being its ability to measure field currents. This capability is a pivotal feature that significantly enhances the model's overall control and monitoring accuracy, making it a valuable asset in various applications.

The board achieves field current measurement through the integration of a shunt within the DC field circuit. This shunt-based approach is instrumental in providing highly precise and accurate measurements of field currents. But what exactly is field current, and why is it so crucial in the realm of control and monitoring systems?

In electrical systems, field current refers to the current flowing through the field winding of a generator or motor. It plays a fundamental role in controlling the strength of the magnetic field generated within the machine. This magnetic field, in turn, has a direct impact on the machine's performance, including its speed, torque, and overall efficiency.

The precise measurement of field currents is of paramount importance for several reasons:

By incorporating a shunt-based approach for field current measurement, the model not only ensures precision but also provides real-time data that is crucial for making informed decisions within the control system. This accuracy is invaluable in applications where even minor deviations from desired parameters can have significant consequences.

World of Controls has the most comprehensive collection of GE Mark VI components. Please contact WOC as soon as possible if you require any extra information.

What is IS200EDFFH2A?

It is a DC fanned feedback board developed by GE

What is the purpose of the fiber-optic link between the EAUX and EDFF boards?

The fiber-optic link provides voltage isolation between the two boards and aids in high-noise immunity.

What type of model is this unit?

This unit is an H2 group model and operates as a dual system.

How many selector settings does the board have?

The board has eight selector settings.

What are the selector settings used for?

The selector settings are used to scale bridge voltages depending on the bridge application.

How many channels does this board have?

The board features 13 channels.

What is the function of this board in a system?

It serves as an I/O Terminal Board, which implies that it likely handles input and output connections in a control or monitoring system.

What is the maximum AC input frequency supported by this board?

The board can handle AC input frequencies up to 480 Hz at maximum.

What is the recommended ambient temperature range for operating this board?

The component is designed to operate within an ambient temperature range of 0 to 40oC.