World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

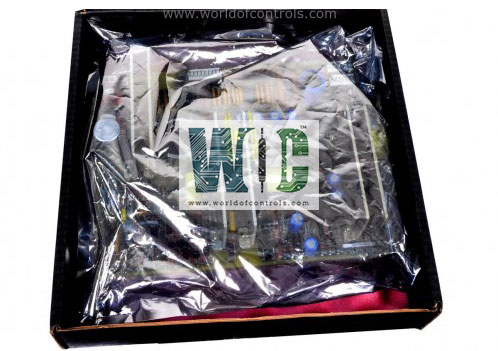

IS200DTBCG2A - Contact Output Termination Module is available in stock which ships the same day.

IS200DTBCG2A - Contact Output Termination Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200DTBCG2A - Contact Output Termination Module, contact us and we will get back to you within 24 hours.

Part Number: IS200DTBCG2A

Manufacturer: General Electric

Series: Mark VIe

Function: Contact Output Termination Module

Availability: In Stock

Country of Manufacture: United States (USA)

IS200DTBCG2A is a Contact Output Termination Module developed by General Electrics. It is a part of GE Mark VIe system. This module plays a role in discrete output signal termination, interfacing between the controller's output drivers and the field-connected contact-based devices such as solenoids, relays, and breakers. DTBC module provides reliable output signal routing, noise isolation, and protection for mission-critical applications in power generation, process automation, and turbine control.

In the Mark VIe architecture, serves as a termination point for contact output signals from the digital core to field actuators. It is typically mounted within a Termination Interface Module (TIM) or I/O cabinet, facilitating organized wiring and shielding, and ensuring signal integrity during output transitions.

The DTBCG2A:

This module is strategically located to optimize signal routing and minimize the distance between the core control logic (such as the I/O packs or controllers) and the final output devices.

Designed for harsh industrial environments, with features that ensure its resilience against:

Protective elements such as transient voltage suppressors (TVS) and snubber circuits are incorporated to protect both the module and connected field equipment from electrical surges and ensure long-term operational stability.

Proper cabling and separation practices are essential for maintaining the performance and reliability of contact output modules in the Mark VIe system. GE recommends strict adherence to signal level separation to minimize crosstalk, interference, and transient coupling.

WOC has the largest stock of Speedtronic control spares. Please contact our staff by phone or email for pricing and availability on any parts and repairs

What is IS200DTBCG2A?

It is a Contact Output Termination Module developed by General Electrics.

What are the key features of the module?

The module is engineered to meet industrial requirements, providing precise control of contact output signals. It is designed to withstand harsh environments and incorporates protective measures against electrical transients and voltage spikes.

How does the board contribute to system reliability?

By efficiently controlling contact output signals, the module enhances system reliability and performance. It ensures accurate and reliable operation even in demanding industrial conditions.

Is the module compatible with the digital core of the Mark VIe system?

Yes, it is designed to be compatible with the digital core of the Mark VIe system. This compatibility enables seamless integration and efficient data transmission within the system.