World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

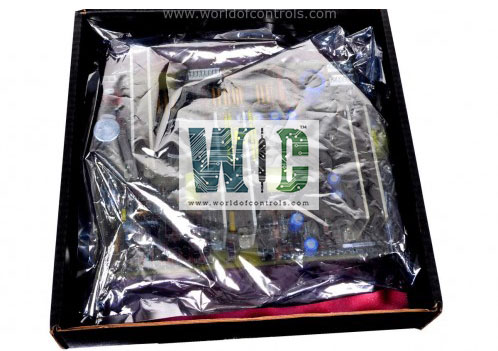

IS200DTBBH1A - Terminal Board is available in stock which ships the same day.

IS200DTBBH1A - Terminal Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS200DTBBH1A - Terminal Board, contact us and we will get back to you within 24 hours.

Part No.: IS200DTBBH1A

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Temperature Operating: 0 to 60 o C

Product Type: Terminal Board

Availability: In Stock

Series: Mark VIe

IS200DTBBH1A is a Terminal Board developed by GE. It is a part of Mark VIe series. It is specifically involved in handling contact inputs and ensuring reliable communication through ribbon cables. It connects with the PMVD and other terminal boards like DTBA, DTBC, and DTBD to enhance diagnostic capabilities.

The terminal board functions as an intermediary for 96 contact inputs that are transferred from other terminal boards such as DTBA, DTBB, DTBC, and DTBD. These inputs are routed to the MVRD application board, which handles the data processing and management tasks.

During installation, it is crucial to securely mount the board to the front core board holder. This secure mounting ensures stable operation and prevents mechanical issues that could affect performance. Additionally, the system requires a wetting voltage greater than 90V to function correctly, ensuring optimal electrical contact and signal reliability.

Incorporates sophisticated verification mechanisms to enhance safety and reliability:

The WOC team is always available to help you with your Mark VIe requirements. For more information, please contact WOC.

What is IS200DTBBH1A?

It is a Terminal Board developed by GE under the Mark VIe series.

What are the installation requirements for the terminal board?

When upgrading to PMVDs from TCDAs, the DTBB (along with DTBA, DTBC, and DTBD) must be securely mounted to the front core board holder. Additionally, a wetting voltage greater than 90V is required for proper operation.

How are ribbon cables verified in the system?

The ribbon cables connecting are verified using sensing logic to detect any broken signal conductors. This ensures that any disconnections or malfunctions in the wiring are promptly identified.

Can external contacts be checked for open wiring in the system?

Yes, external contacts can optionally be checked for open wiring by installing resistors across each contact being checked. This provides an added layer of safety and reliability.