SPECIFICATIONS

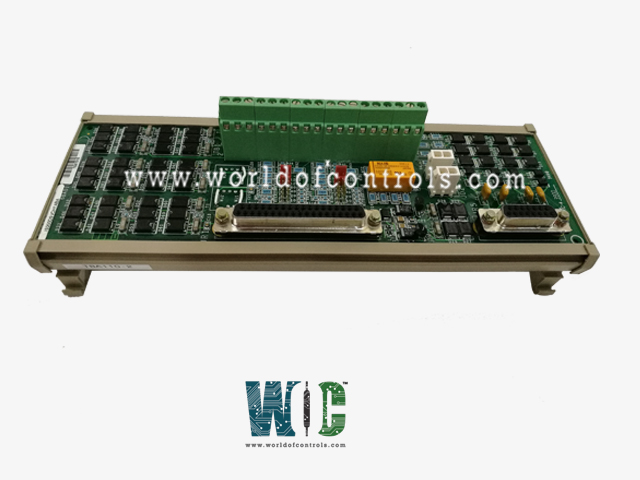

Part No.: IS200DSVOH1ABA

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Size: 23.8 cm high x 8.6 cm wide

Temperature: -30 to +65 oC

Product Type: Servo Terminal Board

Availability: In Stock

Series: Mark VI

Functional Description

IS200DSVOH1ABA is a servo terminal board developed by GE. It is a part of Mark VI control system. The DSVO board serves as a pivotal component within industrial control systems, offering a compact and versatile solution for servo control applications. Designed specifically for DIN-rail mounting, this board integrates seamlessly into control cabinets, optimizing space utilization while delivering robust performance.

Product Features

- Servo Outputs: With two servo outputs, the board enables precise control over servo mechanisms, ensuring smooth and accurate operation in various industrial processes.

- LVDT Position Sensors: The board features inputs for six LVDT position sensors, providing comprehensive feedback on positional data to ensure precise control and monitoring.

- Pulse Rate Inputs: Additionally, the board includes two active pulse rate inputs tailored for flow measurement applications, enabling real-time monitoring of flow rates to enhance process control and efficiency.

- Flexible Servo Coil Current Selection: The board offers flexibility in servo coil current selection, allowing jumper selection of servo coil currents ranging from 10 to 120 mA. This feature enables users to tailor the output to match specific application requirements, ensuring optimal performance and efficiency.

- Connectivity: To facilitate seamless integration into the system architecture, the board connects to the VSVO processor board using a standardized 37-pin cable. This uniformity in connection simplifies installation and ensures compatibility with other system components. Moreover, the identical cables used on the larger TSVO board enhance versatility and ease of maintenance across different board configurations.

- Space Optimization: In scenarios where space conservation is paramount, the boards can be vertically stacked on the DIN-rail, optimizing cabinet space utilization without compromising functionality.

- Scalability: The system architecture allows for the connection of two boards to a single VSVO processor board, providing scalability and flexibility as per application requirements.

Fault Detection Mechanisms

- Servo Current Out of Limits or Non-Responsive: One critical fault detection mechanism involves monitoring the servo current to detect any deviations from predefined limits or non-responsiveness. If the servo current exceeds specified limits or fails to respond as expected, a fault is triggered, indicating potential issues with the servo system.

- LVDT Excitation Out of Range: Another crucial aspect of fault detection is monitoring the LVDT (Linear Variable Differential Transformer) excitation to ensure it remains within the designated range. If the excitation signal strays beyond acceptable limits, it signifies a fault condition, prompting further investigation and corrective action.

- LVDT Feedback Out of Limits: In addition to excitation monitoring, the DSVO board also monitors LVDT feedback signals to detect any anomalies or deviations from expected values. If the feedback signals fall outside predefined limits, indicating potential inaccuracies or malfunctions, a fault is detected and flagged for attention.

- Failed ID Chip: Furthermore, the board incorporates fault detection for ID chips associated with connectors. If an ID chip fails or malfunctions, it triggers a fault condition, signifying potential issues with hardware identification or configuration.

Number of Inputs

- LVDT Windings: With support for 6 LVDT windings, the board enables comprehensive monitoring of positional data from multiple sources. These LVDT inputs provide essential feedback for precise control over servo mechanisms and other dynamic processes.

- Pulse Rate Signals: The board accommodates 2 pulse rate signals, allowing real-time monitoring of flow rates or other pulse-related measurements. These inputs are crucial for applications where accurate flow measurement is essential for process control and optimization.

- External Trip Signal: Additionally, the board features an external trip signal input, enabling the integration of external triggering mechanisms or safety interlocks. This input can be utilized to trigger specific actions or shutdown procedures in response to predefined conditions or events.

Number of Outputs

- Servo Valves: Offers 2 servo valve outputs, allowing precise control over hydraulic or pneumatic actuators. These outputs enable dynamic adjustment of valve positions to maintain desired system parameters or respond to changing operating conditions.

- Excitation Sources for LVDTs: To ensure optimal performance of LVDT position sensors, the board features 2 excitation sources dedicated to LVDTs. These sources provide the necessary excitation signals to power the LVDT sensors, enabling accurate measurement of positional data.

- Excitation Sources for Pulse Rate Transducers: Similarly, the board includes 2 excitation sources specifically for pulse rate transducers. These sources provide the required excitation signals to power the pulse rate transducers, facilitating accurate measurement of flow rates or other pulse-related parameters.

Fault detection

- Servo Current Out of Limits or Not Responding: The module monitors the servo actuator current to ensure proper operation. A fault is triggered if the current exceeds predefined limits or if the servo fails to respond to control commands. This condition may indicate mechanical issues such as actuator binding, electrical faults in the servo drive circuitry, or communication problems between the control system and the actuator. Detecting this fault early helps prevent equipment damage and ensures stable system performance.

- LVDT Excitation Out of Range: The Linear Variable Differential Transformer (LVDT) relies on a stable excitation voltage for accurate position sensing. If the excitation voltage falls outside the acceptable range, the module detects a fault. Potential causes include power supply issues, wiring faults, loose connections, or component degradation within the LVDT or its excitation circuitry. Early detection ensures precise actuator position measurements.

- LVDT Feedback Out of Limits: The module continuously checks the LVDT output signal for deviations. If the feedback exceeds expected limits, it indicates that the actuator position is abnormal or the sensor is malfunctioning. Possible reasons include mechanical misalignment, sensor drift or failure, and electrical interference affecting the signal. Prompt detection allows corrective action to prevent unsafe operation.

- Failed ID Chip: The ID chip in the module ensures proper identification and configuration of connected devices. If the chip fails or is not detected, the module raises a fault to prevent operation with unrecognized or incorrectly configured modules. This safeguards the system from potential misoperation and ensures only verified hardware is in use.

The WOC team is always available to help you with your Mark VI requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS200DSVOH1ABA?

It is a servo terminal board developed by GE under the Mark VI series.

What triggers a fault regarding output servo current?

A fault is triggered if the output servo current is either out of predefined limits or non-responsive, indicating potential issues with the servo system.

How does the system handle faults related to LVDT feedback signals?

If the regulator feedback (LVDT) signal exceeds predefined limits, a fault is triggered. In cases where the associated regulator has two sensors, the faulty sensor is removed from the feedback calculation, and the system continues using the data from the functional sensor.

How does the system handle hardware compatibility issues with connector JR1?

Connector JR1 on the terminal board is equipped with its own ID device, containing vital information such as the terminal board serial number, board type, revision number, and connector location. If a mismatch is encountered when the chip is read by VSVO, a hardware incompatibility fault is created, indicating potential issues with hardware identification or configuration.