SPECIFICATIONS

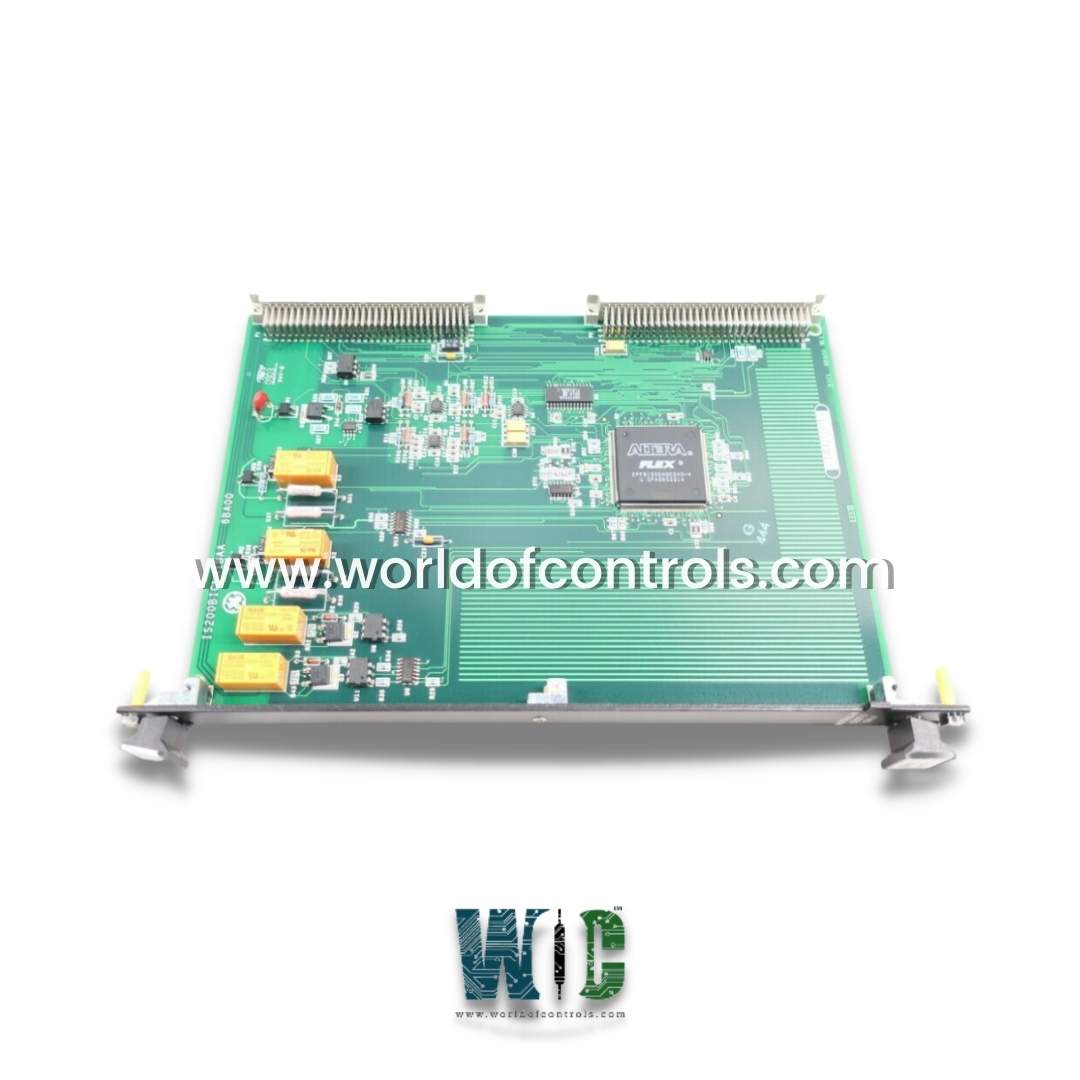

Part No.: IS200BRTDH1A

Manufacturer: General Electric

Series: Mark VI

Number of trip solenoids: Three

Function: Distribution I/O Terminal Board

Repair: 3-5 Days

Availability: In Stock

Product Type: PCB

Country of Manufacture: United States (USA)

Functional Description

IS200BRTDH1A is a Distribution I/O Terminal Board developed by GE. It is a part of Mark VI control system. The Terminal Board acts as an interface between the Mark VI control system and the various input and output devices in the field. It is designed to withstand harsh operating conditions, ensuring uninterrupted and precise data transmission between the control system and field devices. The terminal board is equipped with a wide range of input and output channels, providing flexibility in connecting different types of field devices. It often incorporates multiple communication paths and redundancy mechanisms to ensure data integrity and system resilience.

Operation

- High-frequency decoupling to ground: RTD signals are susceptible to electrical noise and interference. To mitigate these issues, high-frequency decoupling to the ground is implemented at the signal entry points. This technique helps filter out high-frequency noise and ensures that the signals remain stable and free from disturbances, leading to accurate temperature measurements.

- Redundant pacemakers multiplexing: Redundant pacemakers are utilized to coordinate this multiplexing process. These redundant pacemakers ensure that even if one pacemaker fails, the other one takes over seamlessly, preventing any disruption in the multiplexing operation.

- Lossless signal redundancy: To enhance the system's reliability, the design of the boards ensures that the loss of a single cable or module does not lead to the loss of any signals in the control database. This means that even if a cable is damaged or a module malfunctions, the temperature readings from the affected RTDs are still preserved and accessible in the control system.

- Skewed readings for simultaneous multiplexing: The boards in channels R, S, and T are designed to read RTDs simultaneously, but with a specific time skew between them. This means that when one board reads a particular RTD, the others read different RTDs in sequence.

- Ensuring non-simultaneous excitation: By employing the skewed readings strategy, each RTD is excited by only one board at a time.

Characteristics

- Available in different channel configurations, allowing them to accommodate a specific number of input and output signals. The number of channels can range from a few to several dozen, depending on the specific application requirements.

- Support different types of input and output signals. They may have channels for analog signals (such as voltage or current) or digital signals (such as discrete on/off signals). Some boards also support specialty signals like thermocouples or RTDs (Resistance Temperature Detectors).

- These boards provide terminals for connecting wires from field devices. The terminals can be screw terminals, spring-loaded terminals, or a combination of both. The type of terminal used depends on the specific board model and the application's requirements.

- Include signal conditioning capabilities. This feature allows the board to convert, amplify, filter, or linearize the input or output signals as required. Signal conditioning ensures that the signals are in the appropriate format and range for accurate measurement or control.

- Designed to be mounted in control panels or on DIN rails. They typically have standardized dimensions and mounting holes for easy integration into industrial enclosures or control cabinets.

- Built-in communication interfaces, such as Ethernet, Modbus, Profibus, or other industrial protocols. These interfaces enable seamless integration with the control system, allowing for remote monitoring, configuration, and control.

Mark VI Terminal Board Features

- The terminal board serves as a crucial junction in the system, facilitating the connection between the customer's wiring and the intricate network of I/O boards. Its primary function is to distribute signals efficiently to three distinct DC-37 pin connectors, designated for the R, S, and T I/O boards. Each I/O board variant boasts its dedicated terminal board, tailored to its specific requirements, often featuring a unique combination of connectors.

- Consider the thermocouple board, for instance, which manifests in two distinct iterations. In one iteration, the board maintains a simple layout, with a mere duo of connectors that link to a solitary I/O board. Conversely, the alternative version takes on a more complex design, fanning out into an array of six connectors, each designated for the R, S, and T interfaces. It's worth noting that this intricate fan-out circuitry introduces a potential single point of failure. Consequently, the terminal board has been meticulously engineered to include only a minimal amount of active circuitry. This circuitry is predominantly composed of filters and protective devices, safeguarding against potential malfunctions and disruptions.

- For the sake of redundancy and reliability, the power supply for the outputs is generally sourced from the respective I/O boards. However, there are exceptions to this norm, particularly in cases involving relay and solenoid outputs. In these instances, independent power plugs are thoughtfully integrated onto the terminal board. This design strategy not only streamlines power distribution but also enhances the system's modularity and versatility.

World of Controls has the most comprehensive collection of GE Mark VI components. Please contact WOC as soon as possible if you require any extra information.

Frequently Asked Questions

What is IS200BRTDH1A?

It is a Distribution I/O Terminal Board developed by GE

What are the primary functions of an HMI?

The main functions of an HMI are to provide operators with real-time data visualization, process control capabilities, and access to critical system information. It serves as a bridge between the human operator and the industrial process, allowing for monitoring, control, and analysis of various parameters.

What can operators do with real-time graphic displays?

Operators can interact with real-time graphic displays to monitor the status of different process variables, visualize the operation of machinery, track alarms and faults, and initiate control commands. The real-time graphic displays provide an intuitive and dynamic representation of the industrial process.

What is CIMPLICITY software, and how does it enhance the HMI functionality?

CIMPLICITY is operator display software that forms the core of the HMI system. It offers a user-friendly interface for operators to access critical information, control processes, and respond to alarms effectively. It enables seamless integration of data from various sources, making it easier for operators to make informed decisions.