World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

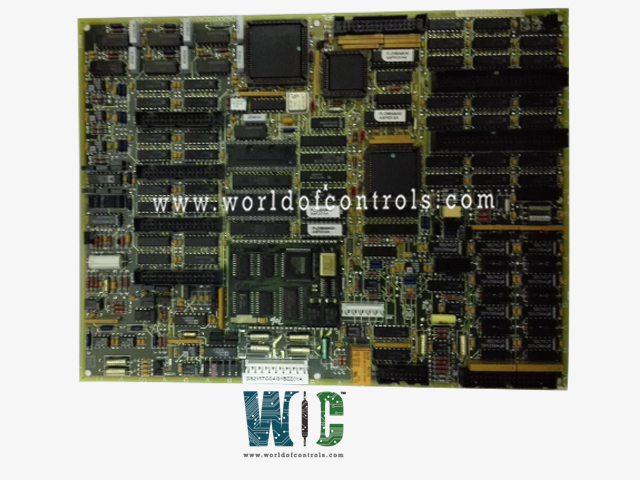

DS200TCCGA1ADA - Common Analog I/O Board is available in stock which ships the same day.

DS200TCCGA1ADA - Common Analog I/O Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCCGA1ADA - Common Analog I/O Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS200TCCGA1ADA

Manufacturer: General Electric

Series: Mark V

Product Type: Common Analog I/O Board

Analog Output Channels: 4 / 8 channels

Analog Input Channels: 8 / 16 channels

Output Signal Types 0–10V, 4–20 mA

Input Signal Types 0–10V, 4–20 mA, ±10V

Input Impedance: >100

Accuracy: ±0.1%

Isolation Voltage: 1500 VDC

Resolution: 12-bit

Power Supply: 24V DC ±10%

Operating Temperature: -20°C to +60°C

Mounting Options: DIN rail / Panel mount

Communication Interfaces: Modbus RTU

Size: 8.26 cm high x 4.18 cm

Repair: 3-7 days

Availability: In Stock

Weight: 2 lbs

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS200TCCGA1ADA is a Common Analog I/O Board manufactured and designed by General Electric as part of the Mark V Series used in GE Speedtronic Gas Turbine Control Systems. A Common Analog I/O Board is an essential component in industrial control and automation systems. It acts as an interface between analog field devices, such as sensors and actuators, and a central processing unit, like a PLC or DCS. These boards are capable of handling various types of analog signals, including voltage and current, to accurately read physical parameters such as temperature, pressure, level, and flow. In addition to reading input data, they also provide analog outputs that can be used to control devices such as valves, motors, and other actuators. Their robust design ensures high accuracy, fast response, and reliable operation in demanding industrial environments.

INSTALLATION:

The board should be mounted in a clean and dry enclosure, typically within a control cabinet. Mounting options may include DIN rail or panel mounting based on the design. Wiring must be done carefully, connecting analog input signals from transmitters or sensors to designated input terminals and connecting analog output terminals to final control elements. It is important to follow the correct polarity and signal types, and it is recommended to use shielded cables to minimize electrical interference. Some boards may require DIP switch settings or software configuration to define signal types and ranges. After installation and configuration, initial testing should be performed using a multimeter or HMI to verify correct signal processing and communication with the controller.

OPERATIONS:

It continuously operates by converting physical process signals into digital signals that a controller can interpret, and vice versa. For analog inputs, it takes real-world signals from field instruments, such as 0–10V or 4–20 mA, and converts them into a digital format. For analog outputs, it receives digital control signals from the processor and converts them back into analog signals to control external equipment. Many boards incorporate built-in signal conditioning features, including isolation, filtering, and amplification, to ensure accurate and noise-free data transmission. Advanced models may also offer diagnostic capabilities such as over-range detection, fault status LEDs, and error flags that help identify and troubleshoot issues in real time.

WOC maintains the largest inventory of Replacement parts for GE Speedtronic control systems. Additionally, we offer warranty-backed unused and rebuilt boards as well as board repairs for your damaged ones. For your OEM needs, our team of professionals is available around the clock. We at WOC are happy to help you with any needs you may have in terms of automation. Please contact our team by phone or email for pricing and availability on any components and repairs.

What types of sensors can be connected to the analog input channels?

The Common Analog I/O Board supports the integration of industrial-grade analog sensors that operate within standard signal ranges such as 0–10V, ±10V, and 4–20 mA. Compatible devices include pressure transducers, thermocouples, and RTDs (with signal conditioners), capacitive and ultrasonic level sensors, linear potentiometers, and pH/ORP transmitters.

Does the board provide galvanic isolation?

Yes, the board features channel-to-channel and channel-to-system galvanic isolation typically rated at 1500 VDC or higher. This isolation is crucial for eliminating ground loop errors, reducing common-mode noise, and protecting sensitive signal paths from high-voltage transients.

What is the resolution of the analog I/O board, and how does it affect accuracy?

The resolution of the analog I/O board refers to the smallest change it can detect in the input or output signal and is typically expressed in bits, commonly 12-bit or 16-bit. A 12-bit converter provides 4096 discrete levels, while a 16-bit converter offers 65,536 levels.