World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

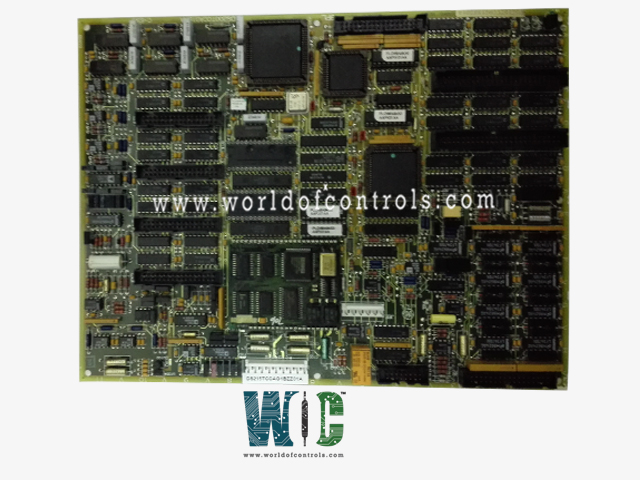

DS200TCCGA1A - Common Data Processor Board is available in stock which ships the same day.

DS200TCCGA1A - Common Data Processor Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200TCCGA1A - Common Data Processor Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS200TCCGA1A

Manufacturer: General Electric

Series: Mark V

Board Type: Common Data Processor Board

Processor: 32-bit ARM Cortex-R5, 400 MHz

Memory: 512 MB SDRAM, 16 MB Flash

Input Channels: 32 Analog Inputs

Output Channels: 16 Analog Outputs

Communication Interfaces: Dual redundant CAN Bus

Deterministic Control: Cycle time

Redundancy: Dual-redundant processor configuration

Operating Temperature: 0°C to 70°C

Power Supply: 24 V DC

Mounting: 19-inch

Board Size: 15.7 cm High x 18.5 cm

Repair: 3-7 Days

Weight: 2.00 lbs

Country of Origin: USA

Availability: In Stock

FUNCTIONAL DESCRIPTION:

DS200TCCGA1A is a Common Data Processor Board manufactured and designed by General Electric as part of the Mark V Series used in GE Speedtronic Gas Turbine Control Systems. The Common Data Processor Board serves as the central processing unit within the turbine control system, responsible for executing high-speed computations, logic operations, and real-time data management. It acquires input signals from sensors and field devices, processes the data using embedded algorithms, and generates precise control outputs to actuators and other system modules. The board ensures synchronization across multiple modules, facilitates communication with redundant systems for reliability, and monitors operational status, alarms, and diagnostic information. Its design supports deterministic processing, fault-tolerant operation, and seamless integration with the overall turbine control architecture, providing accurate and stable system control under varying operational conditions.

OPERATION:

It executes embedded control algorithms in real time, processes the data to determine system states, and generates precise output signals to control actuators and peripheral modules. The board manages communication with redundant processors, synchronizes data across multiple channels, and ensures deterministic execution for high-speed, stable turbine control. It also monitors system health, detects faults, and triggers alarms or protective actions when operational parameters exceed defined limits, maintaining safe and reliable system operation.

KEY FEATURES:

It continuously acquires input signals from sensors, field devices, and other control modules, processes the information using embedded control algorithms, and generates precise output signals to actuators and peripheral modules. The board ensures synchronization across multiple channels, communicates with redundant processors for fault-tolerant operation, and maintains deterministic execution for stable turbine control. It also monitors system health, detects faults, logs events, and triggers alarms or protective actions when operational parameters exceed defined limits, ensuring safe and reliable system performance.

World of Controls offers the largest stock of GE Speedtronic Gas Turbine control system replacement parts, including both brand-new and expertly rebuilt boards, all backed by a full warranty to ensure reliability and performance. In addition to supplying critical components, WOC provides specialized repair services, restoring faulty boards to OEM standards for safe and efficient turbine operation. Our team of automation specialists is available 24/7 to provide technical guidance, troubleshooting, and support for system integration, diagnostics, and preventive maintenance. With immediate access to parts, expert repairs, and around-the-clock assistance, WOC ensures minimal downtime and optimal performance for your turbine control systems.

What is the primary function of the CDP Board?

The CDP Board acts as the central processing unit in the turbine control system. It acquires input data from sensors and field devices, executes control algorithms in real time, and generates precise output signals to actuators and peripheral modules.

How does the CDP Board ensure fault-tolerant operation?

It communicates with redundant processors and synchronizes data across multiple channels. In case of a processor failure, the board automatically switches to the backup processor, maintaining continuous and reliable operation.

What types of input and output signals does the CDP Board support?

It supports analog inputs (0–10 V / 4–20 mA), digital inputs (24 V DC), analog outputs (0–10 V / 4–20 mA), and digital outputs (24 V DC) for full system control and monitoring.

How does the CDP Board handle redundant processor communication?

The board synchronizes data with redundant processors over dual-redundant communication channels. In case of a processor failure, it switches seamlessly to the backup processor to maintain uninterrupted operation.