World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

DS200FCRLG1AFC - Firing Circuit Control Board is available in stock which ships the same day.

DS200FCRLG1AFC - Firing Circuit Control Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS200FCRLG1AFC - Firing Circuit Control Board, contact us and we will get back to you within 24 hours.

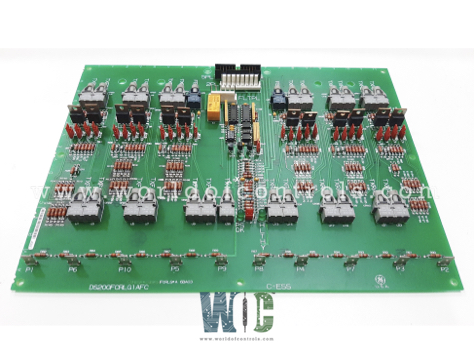

Part Number: DS200FCRLG1AFC

Manufacturer: General Electric

Series: Drive Control

Product Type: Firing Circuit Control Board

Size: 9.2x6.3 inches

Temperature 0 to 60oC (32 to 149 oF)

Availability: In Stock

Country of Manufacturer: United States (USA)

DS200FCRLG1AFC is a Firing Circuit Control Board developed by General Electric. It is a part of Drive Control series. The PCB is equipped with 27 bayonet-type connectors, 27 jumpers, 1 34-pin connector, and 1 9-pin connector, facilitating connectivity with various signal and power cables. These connectors are crucial for establishing communication and power supply within the system.

WOC has the largest stock of Speedtronic control spares. Please contact our staff by phone or email for pricing and availability on any parts and repairs

What is DS200FCRLG1AFC?

It is a Firing Circuit Control Board developed by General Electrics.

How does the control system ensure safe and efficient turbine operation?

The control system regulates turbine speed, monitors pressure levels, coordinates with the generator for power generation, and implements protective measures to prevent hazards such as overspeed, loss of lube oil pressure, and high temperatures, ensuring both safety and efficiency.

What role does pressure control play in steam turbine operation?

Pressure control is crucial for maintaining optimal operating conditions within the turbine system. It involves regulating various pressure parameters, including inlet pressure, extraction pressure, and back pressure, to ensure efficient power generation and prevent equipment damage.

How does the control system manage turbine startup and shutdown?

During startup, the control system controls speed and acceleration, initializes generator excitation, and synchronizes with the electrical grid. For shutdown, it unloads the turbine safely and secures it to prevent damage or hazards.