SPECIFICATIONS

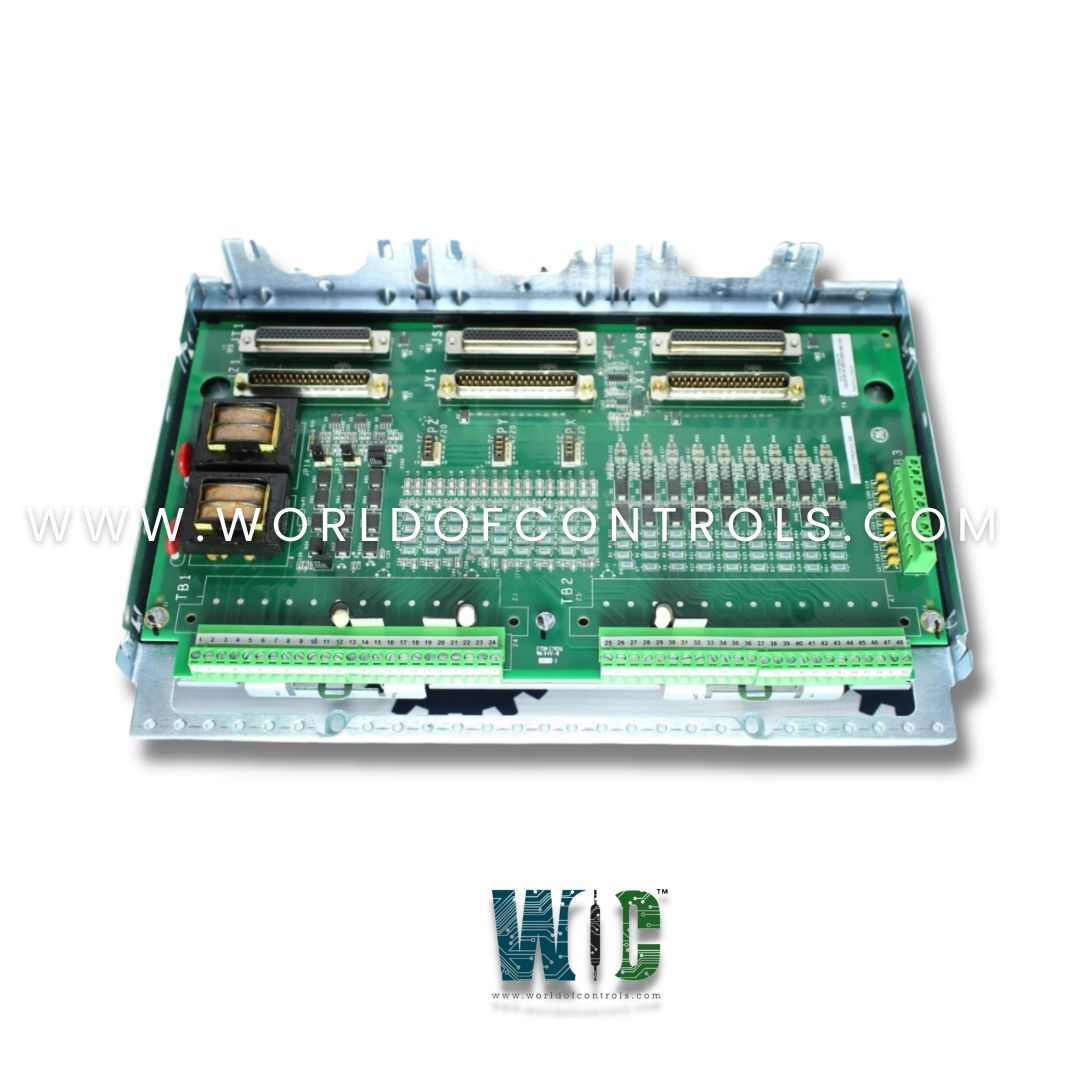

Part No.: IS230TPROH2C

Manufacturer: General Electric

Product Type: Emergency Protection Terminal board

DC-37 pin conductor cables: 3

Dimensions: 15.9 cm x 17.8 cm

Jumper switches: JPA1, JPB1

Technology: Surface-mount

Frame rate: 100 Hz

Input supply: 125 VDC

MPU Pulse rate range: 2Hz to 20KHz

Temperature: -30 to 65 degrees Celsius

Series: Mark VIe

Availability: In Stock

Manual: GEH-6721

Country of Manufacture: United States (USA)

Functional Description

IS230TPROH2C is an emergency protection terminal board developed by GE. Three PPRO I/O packs are housed on the Emergency Protection (TPRO) terminal board. It conditions the PPROs' speed signal inputs and has a pair of potential transformers (PTs) for bus and generator voltage input. It has three DC-37 pin connectors, one on each side of the PPRO pack connectors. A cable leading to a Mark VIe backup trip relay terminal board is accepted by each DC-37. It has two Euro-style box terminals with 24 plugs. As part of an independent emergency overspeed and synchronization protection system, TPRO sends speed signals, temperature signals, generator voltage, and bus voltage to the VPRO. The protection system consists of three redundant VPRO boards in a module separate from the turbine control system, with TREx (TREG, TREL, or TRES) regulating the trip solenoids. TPRO feeds inputs to all three VPRO boards.

Features

- The emergency trip capability is provided by the VPRO board. Between the TREx and TRPX (TRPG, TRPL, or TRPS) terminal boards, up to three trip solenoids can be connected. The positive side of the 125 V de to the solenoids is provided by TREX, while the negative side is provided by TRP. The turbine can be tripped by either board. VPRO has emergency overspeed protection as well as emergency stop functions. It manages TREG's 12 relays, nine of which comprise three groups of three to handle the three trip solenoids. From VPRO, a second TREG beard can be driven through 34. It does not support the Mark Vie LC packs.

- The board provides generator voltage, bus voltage, temperature signals, and speed signals to the VPRO. It is part of the VPRO independent emergency overspeed protection system.

- It is constructed with two terminal strips (blocks) on the board's front edge. These terminal strips each have 24 positions. If/when these components require maintenance, they can be unplugged from the board. A smaller terminal strip can be found along the right edge of the board.

- Two transformers are located next to MOVs along the right edge of the board (metal oxide varistors)

Installation Guidelines

- Mounting on a Sheet Metal Carrier: Along with the plastic insulator, is mounted on a sheet metal carrier. The carrier provides structural support and protection for the module. It is designed to be compatible with DIN-rails, which are commonly used in industrial environments for standardized mounting. The module and insulator are securely attached to the carrier, ensuring stability during operation.

- Mounting on a Sheet Metal Assembly: Alternatively, the TPROH2C module and insulator can be mounted on a sheet metal assembly. This assembly can be directly bolted into a panel, offering flexibility in installation options. This method allows for organized and compact installation within a panel, ensuring easy access and maintenance of the module.

- Wiring Connections: Typical 18 AWG wires are used to connect speed signals and PT (Pressure Transmitter) inputs to the terminal block on the TPROH2C module. These wires carry the input signals from the speed sensors and PT transmitters, allowing for monitoring and control of the corresponding parameters. The use of standard #18 AWG wires ensures compatibility and proper signal transmission.

- Detachable Barrier Terminal Block: Features a detachable barrier terminal block. This terminal block is a Euro-Block pluggable terminal block with removable terminals. The detachable nature of the terminal block allows for easy replacement of the board if needed, simplifying maintenance and minimizing downtime.

- Installation of PPRO I/O Packs: The R, S, and T PPRO I/O packs are installed on the TPRO connectors JR1, JS1, and JT1, respectively. These I/O packs provide additional input/output capabilities for the module. They allow for the connection and control of external devices, expanding the functionality and flexibility of the control system.

- Connection of DC-37 Pin Conductor Cables: The module has three DC-37 pin conductor cables, which are plugged into the TPRO connectors JX1, JY1, and JZ1. The other ends of these cables are connected to the backup trip terminal boards of choice. This connection facilitates communication between the TPROH2C module and the backup trip terminal boards, ensuring coordinated operation and redundancy in critical scenarios.

Compatibility

- It offers excellent compatibility with the PPRO I/O pack, making it a versatile component within the control system. It is specifically designed to work seamlessly with the PPRO I/O pack, allowing for easy integration and expanded functionality.

- The compatibility extends to both simplex and TMR (Triple Modular Redundant) applications. In simplex applications, the TPROH2C module can be used as a standalone unit, providing control and monitoring capabilities for a single controller. It connects directly to the PPRO I/O pack, enabling the control system to interface with external devices and equipment.

- In TMR systems, the module plays a vital role. It is designed to connect to three I/O packs, one for each of the TMR controllers in the system. This configuration enhances redundancy and fault tolerance. By distributing the control signals among multiple controllers and I/O packs, the TMR system ensures continuous operation even in the presence of failures or maintenance activities.

- The TPROH2C module serves as a crucial link between the TMR controllers and the I/O packs, facilitating seamless communication and data exchange. It enables synchronized control and monitoring across the system, ensuring accurate and reliable operation in TMR applications.

- The compatibility of the module with the I/O pack in both simplex and TMR applications allows for flexible and scalable system configurations. Whether in a single controller setup or a redundant TMR configuration, the TPROH2C module provides the necessary connectivity and functionality to meet the specific requirements of the industrial process.

Operation

- Terminals 31-48 on the module are dedicated to nine speed inputs. These inputs allow for the monitoring and control of speed-related parameters in the industrial process. Signals from speed sensors or other speed measurement devices are connected to these terminals, enabling the module to process and utilize the speed information.

- Terminals 5, 9, and 11 provide the customer with the P24 output. The P24 output is a 24 V power supply that can be used to power external devices or components. This output voltage facilitates the operation of connected equipment or serves as a power source for other control devices.

- Terminal 8, labeled as MARET, serves as the return path for the P24 output. It completes the circuit for the P24 power supply, ensuring proper functioning of the connected devices.

- The P24 output is generated by ORing the 28 V power supplies of the R, S, and T PPRO I/O packs. This configuration combines the power supplies from these packs, providing a consolidated P24 output voltage. Even if an individual I/O pack is turned off, the P24 V output remains accessible, ensuring continuous power availability for the connected devices.

- Terminals 6, 10, and 12 on the module are reserved for future control expansions. These terminals are fanned to the R, S, and T PPRO connectors, allowing for potential expansions or additional control functions to be integrated into the system. These reserved terminals provide flexibility for future enhancements without the need for significant modifications to the existing wiring.

- Terminal 8, identified as MARET, also serves as the return path for the 4-20 mA input. This input is commonly used for receiving analog signals, such as current measurements from sensors or transmitters. Terminal 8 ensures the proper return path for the 4-20 mA input, completing the circuit and allowing for accurate measurement and control of analog signals.

Power supply

Configuration

- Individual Board Power Supply: Each board within the protection module is equipped with its power supply system integrated on the board itself.

- Voltage Outputs: This internal power supply generates two distinct output voltages: 5 V dc and 28 V dc. These voltage outputs are derived from the 125 V dc supplied by the cabinet PDM (Power Distribution Module).

- Reliability Enhancement: The provision of dedicated power supplies for each board contributes significantly to the overall reliability of the protection module. This redundancy ensures continued functionality even in the event of a failure in one power supply, promoting system resilience.

TREG Control by VPRO

- Control Dynamics: The TREG (Turbine Regulator) is under the complete control of the VPRO (Voltage Regulator Power Module).

- Control Connectivity: Only the J2 power cable and the trip solenoids establish a connection between the control modules, simplifying the interconnection setup.

- Trip Signal Transmission: A third cable serves the purpose of carrying a trip signal from J1 to the terminal board in simplex systems.

- Functionality in Simplex Systems: In simplex systems, this trip signal plays a critical role by providing a servo valve clamp function upon the occurrence of a turbine trip. This function is crucial for ensuring the proper response and safety measures following a turbine trip event.

World of Controls has the most comprehensive collection of GE Mark VIe components. Please contact WOC as soon as possible if you require any extra information.

Frequently Asked Questions

What is IS230TPROH2C?

It is an emergency protection terminal board developed by GE

What components are located on the front edge?

It has two terminal strips (blocks) located on the front edge of the board. Each of these terminal strips has 24 positions, and these components can be unplugged from the board for maintenance.

What is the function of the transformers located on the right edge?

The two transformers located along the right edge of the board are used to condition the voltage input signals for the VPRO.

What are the jumper switches used for?

The two jumper switches (JPA1 and JPB1) are used to configure the board. These jumpers should only be changed with the help of a qualified technician.