World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

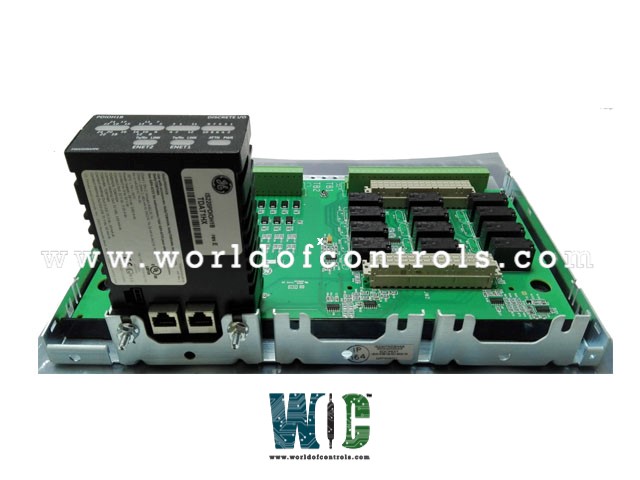

IS230TNCIH5C - Contact Input DIN Rail Module is available in stock which ships the same day.

IS230TNCIH5C - Contact Input DIN Rail Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS230TNCIH5C - Contact Input DIN Rail Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: IS230TNCIH5C

Manufacturer: General Electric

Series: Mark VIeS

Module Type: Contact Input / Discrete Input DIN Rail Module

Number of Channels: 24

Input Voltage: 24 V DC

Technology: Surface Mount

Common Mode Voltage Range: �5 V

Dimensions: 11.00 x 9.00 x 3.00

Operating temperature: 0 to 60 Deg C

No.of Ribbon Cable Connectors: Two, 20-pin

No.of VMEbus Connectors Two, 96-pin

Mounting: 35 mm DIN Rail

Repair: 3-7 days

Availability: In Stock

Country of Origin: United States

Manual: GEH-6721D

FUNCTIONAL DESCRIPTION:

IS230TNCIH5C is a Contact Input DIN Rail Module manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Turbine Control Systems. The Contact Input DIN Rail Module functions as a discrete input interface between external field devices and the control system logic. It is designed to detect binary ON/OFF signals from switches, relays, sensors, or other contact-type devices and convert them into logic-level signals readable by the Mark VIe/VIeS control system. The module provides electrical isolation between field wiring and internal control electronics to protect against noise, ground loops, and transient voltages, ensuring reliable signal transmission. In redundant configurations, such as Triple Modular Redundancy (TMR), multiple input packs operate in parallel, with the control system using a voting mechanism to determine accurate input states, thereby enhancing reliability and fault tolerance in safety-critical applications. The module also supports diagnostic and status monitoring, often via onboard LEDs or control-system feedback, enabling maintenance and troubleshooting of discrete inputs without disrupting operations.

INSTALLATION:

Mount the module on a standard 35 mm DIN rail inside a control cabinet or panel using the built-in DIN-rail clip or hook mechanism. Ensure the rail is securely fixed. Installation typically involves placing the top of the module onto the rail and snapping the lower clip into place. Always turn off power to the I/O rack or bus before mounting to prevent electrical hazards or arcing, especially in industrial control environments.

After mounting, connect field-device wiring�such as contacts, sensors, or switches�to the module via its terminal board (or associated terminal interface for input modules). Follow the manufacturer�s wiring diagram and ensure the use of correct wire gauge and proper shielding or grounding to reduce electrical noise.

Ensure the module is grounded according to the control cabinet�s grounding scheme. Many control systems include a dedicated functional ground or shield terminal connected to earth ground for EMI mitigation and safety compliance.

Maintain proper spacing or ventilation around the module if required by the cabinet layout. Industrial I/O modules are designed to operate within specified ambient temperature limits and typically require some airflow within the enclosure to avoid overheating.

OPERATION:

Whenever an external contact�such as a relay contact, switch, or sensor�closes or opens, the module detects the state change and converts it into a digital logic signal for the control system. This discrete input is then transmitted over the I/O network to the controller. The module�s electrical isolation ensures that noise, ground potential differences, or interference on the field side do not propagate to the internal logic, preserving signal integrity and ensuring safe operation. In redundant (TMR) configurations, three identical input packs operate in parallel, and the controller uses a voting algorithm (such as 2-out-of-3) to determine the correct input state, preventing false readings due to a single-pack failure.

The module may include diagnostic or status indicators (such as LEDs) per input channel or per module for visual verification of input states and fault conditions, depending on the design. Many discrete input modules in similar systems use such indicators to simplify maintenance and troubleshooting. The module then transmits the digitized input data to the control system I/O network (e.g, IONet or the Mark VIe I/O bus), allowing higher-level control logic, alarms, interlocks, and process sequences to respond appropriately.