World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS230TNCIH3C - Contact Input DinRail Module is available in stock which ships the same day.

IS230TNCIH3C - Contact Input DinRail Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS230TNCIH3C - Contact Input DinRail Module, contact us and we will get back to you within 24 hours.

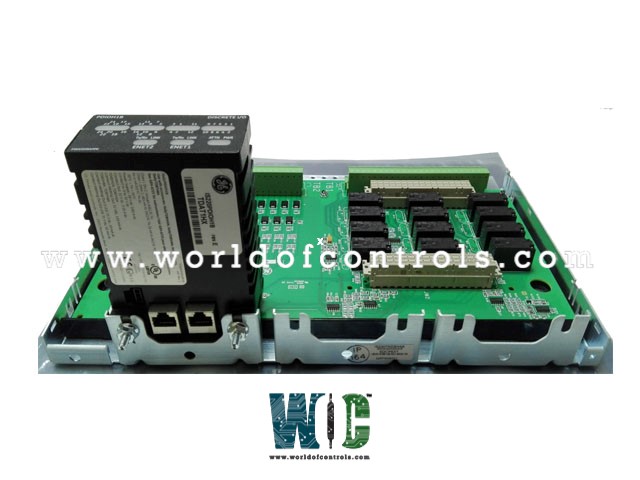

Part Number: IS230TNCIH3C

Manufacturer: General Electric

Series: Mark VIe

Function: Contact Input DinRail Module

Humidity: 5-95 percent

Redundancy Type: Simplex, Dual, TMR

Availability: In Stock

Product type: PCB

Country of Manufacture: United States (USA)

IS230TNCIH3C is a Contact Input DinRail Module developed by GE. It is a part of Mark VIe control system. The Mark VI series comprises a comprehensive range of modules and components that are designed to work together seamlessly, providing precise control, efficient data management, and reliable system performance. The module consists of twenty-five metal oxide varistors and two three-pin female plug connectors.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is IS230TNCIH3C?

It is a Contact Input DinRail Module developed by GE.

What are the communication types supported by the module?

The component supports two main communication types within the Mark VIe control system: Unit Data Highway (UDH) and IONet. These communication options enable seamless data exchange and connectivity between various control system components, facilitating efficient and reliable system operation.

What is the operating humidity range of the product?

The product is designed to operate in a humidity range of 5 to 95 percent non-condensing. This wide humidity tolerance ensures reliable performance even in environments with varying humidity levels, making it suitable for deployment in diverse industrial settings.

What types of redundancy does the module support?

It supports multiple redundancy options to enhance system reliability. It is compatible with simplex, dual, and TMR (Triple Modular Redundancy) architectures. These redundancy configurations ensure that the control system can withstand component failures and continue to operate without interruptions, contributing to the overall robustness and fault tolerance of the system.