SPECIFICATIONS

Part No.: IS230TBAI1CG

Manufacturer: General Electric

Number of channels: 24

Input filter: Hardware filter, 4 ms

Temperature rating: 0 to 60oC

Technology: Surface-mount

Size: 33.02 cm high x 10.16 cm wide

Availability: In Stock

Power consumption: 20.6 watts

Temperature rating: 0 to 60 oC

Country of Manufacture: United States (USA)

Series: Mark VIe

Functional Description

IS230TBAI1CG is an Analog I/O Module developed by GE. It is a part of the Mark VIe control system.The board features 10 analog input channels and 2 analog output channels, accommodating a variety of sensor configurations such as two-wire, three-wire, four-wire, externally powered transmitters, and ±5 V/±10 V voltage inputs. Outputs are configurable for 0–20 mA or 0–200 mA, supporting both standard and high-current control devices.

Analog Input/Output Capabilities

This module provides 10 analog input channels and 2 analog output channels, making it suitable for interfacing a wide variety of field instrumentation. The input channels are designed to accommodate:

- Two-wire transmitters (loop-powered),

- Three-wire and four-wire transmitters (externally powered), and

- Externally powered analog sensors.

Each analog input is equipped with noise suppression circuitry, offering robust protection against:

- Electrical surges,

- Common-mode interference, and

- High-frequency noise can otherwise compromise signal fidelity in electrically noisy industrial environments.

The analog outputs on the TBAI board are configurable to operate in either:

- 0–20 mA, or

- 0–200 mA current loop ranges.

This allows compatibility with various final control elements, such as control valves and actuators that rely on analog signaling for position or flow control.

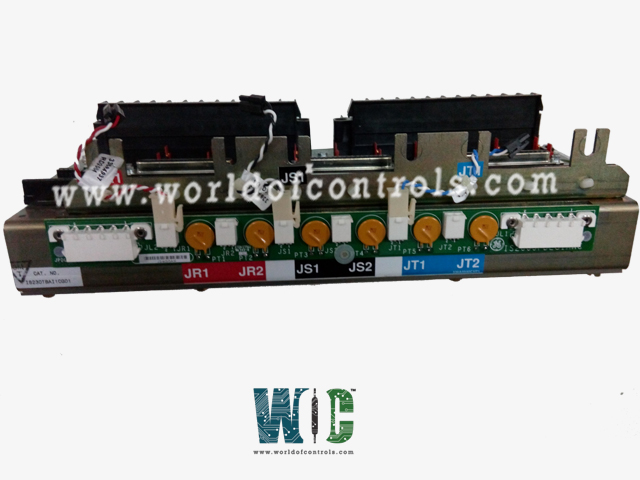

Interface and Redundancy

The board provides three DC-37 pin connectors to interface with the Mark VIe I/O processors:

- JR1: Used for simplex (single-channel) configurations.

- JR1, JR2, JR3: All three are used in TMR (Triple Modular Redundant) architectures.

In TMR mode, the analog input signals are fanned out across all three connectors, delivering the same signal to the R (Red), S (Silver), and T (Turquoise) control processors. This redundant architecture allows the system to perform fault-tolerant voting and ensures system availability even in the event of hardware failure in one channel.

TMR Analog Output Handling

For analog outputs in TMR configurations, it employs a summation method. Each of the three output drivers (one per controller) contributes to the total output current. A precision shunt resistor on the terminal board measures this aggregate current, which is then:

- Fed back to the control electronics,

- Compared to the commanded output value, and

- Regulated accordingly to maintain precise control of output.

This strategy ensures output integrity even when one or more controller channels deviate, contributing to high system reliability and accuracy in mission-critical control loops.

Installation Procedure

- Terminal Block Configuration: The terminal board features two I/O terminal blocks that facilitate direct wiring of the 10 analog input channels and 2 analog output channels. Each block contains 24 screw-type terminals, providing ample space for field connections. The terminals are designed to accept wire sizes up to #12 AWG, which is suitable for low-resistance, long-distance connections. Each terminal block is secured to the board with two screws, ensuring a robust mechanical connection and resistance to vibration—critical for operation in industrial environments such as power plants and turbine enclosures.

- Shield Terminal Integration: To enhance signal integrity and reduce susceptibility to electromagnetic interference (EMI), a shield terminal is located adjacent to each terminal block. These shield terminals provide a grounding point for cable shielding or drain wires, helping to minimize noise coupling, particularly in installations involving long cable runs or environments with high electrical noise. Proper use of these shield terminals is essential for maintaining accuracy in analog signal measurements and ensuring system stability.

- Supported Analog Input Types: Supports a diverse range of analog input configurations, making it suitable for a wide variety of sensors and transmitters used in industrial process control. The supported input types include:

- Two-wire transmitters, which receive both power and signal over the same pair of wires are commonly loop-powered via the control system’s 24 VDC supply.

- Three-wire transmitters, which provide separate power and signal ground lines, offer improved noise immunity.

- Four-wire transmitters, ideal for high-precision applications, where both power and signal paths are isolated.

- Externally powered transmitters operate independently of the terminal board's excitation supply.

- Voltage input sources, supporting 5 VDC and 10 VDC input ranges, which are useful for interfacing with various control or monitoring equipment that outputs voltage signals instead of current.

- Analog Output Capabilities: For actuator and control output applications, the terminal board provides two analog output channels. These outputs can be configured for either 0–20 mA or 0–200 mA current loop operation. The 0–20 mA configuration is widely used for standard analog signal control, such as driving I/P converters, control valves, or external PLC analog input cards. The 0–200 mA option caters to high-current control devices that demand stronger drive signals. Output integrity is maintained through internal summing and regulation logic in TMR systems, ensuring reliable control output even in the event of partial redundancy loss.

- Installation Best Practices: During installation, it is crucial to observe proper wire termination and shielding techniques to maintain signal quality and ensure system longevity. Use appropriate wire gauges and torque specifications for terminal screws. Always connect cable shields to the provided shield terminals, and follow GE’s grounding and bonding recommendations. These practices will reduce the risk of signal degradation, ground loops, and EMI-related failures—especially in high-noise industrial environments such as generator halls or substations.

World of Controls has the most comprehensive collection of GE Mark VIe components. Please contact WOC as soon as possible if you require any extra information.

Frequently Asked Questions

What is IS230TBAI1CG?

It is an Analog I/O Module developed by GE.

What are the available analog output ranges?

It supports 0–20 mA current outputs (standard control applications) and 0–200 mA current outputs (high-current applications).

How is the wiring configured on the terminal board?

The board features two terminal blocks, each with 24 screw-type terminals. These accept wires up to 12 AWG. A shield terminal is located near each block for proper grounding and noise suppression.

Does the board include surge protection or noise suppression?

Yes. The analog inputs and outputs include built-in noise suppression and protection circuitry to safeguard against electrical surges and high-frequency noise, ensuring signal integrity in harsh environments.