SPECIFICATIONS

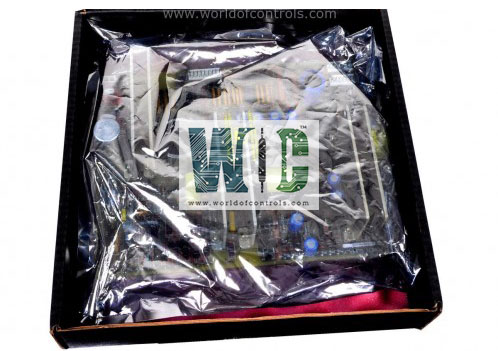

Part No.: IS230SHRSH1A

Manufacturer: General Electric

Function: DIN-Rail Mounted I/O Module

Country of Manufacture: United States (USA)

Size - 17.8 cm wide x 33.02 cm high

Temperature -30 to + 65oC

Technology Surface-mount

Product Type: PCB

Availability: In Stock

Series: Mark VIe

Functional Description

IS230SHRSH1A is a DIN-Rail Mounted I/O Module developed by GE. The I/O Module is designed to be mounted on a DIN rail, offering seamless integration into existing system. It provides a compact and space-saving solution, allowing for easy installation and maintenance. Equipped with advanced features and robust construction, it is built to withstand demanding operating conditions commonly encountered in industrial environments. Its rugged design guarantees durability and resilience, enabling it to perform consistently even in harsh and challenging settings. One of the key advantages of the I/O Module is its versatility and flexibility in handling different types of inputs and outputs. It offers a wide range of digital and analog inputs, enabling the connection and monitoring of various sensors, switches, and devices. Additionally, it provides multiple output channels that can be utilized for controlling actuators, relays, and other external devices, thus facilitating seamless automation and control processes.

I/O Types

- When it comes to I/O (input/output) options for industrial applications, there are two distinct types available: general purpose I/O and turbine specific I/O. Each type serves specific purposes and offers unique advantages in different industrial contexts.

- General purpose I/O is a versatile option that finds applications in both turbine systems and general process control. It provides a flexible interface for connecting and controlling various sensors, switches, and actuators across different industrial processes. With general purpose I/O, users have the freedom to monitor and control a wide range of devices, enabling efficient automation and supervision of diverse industrial operations.

- On the other hand, turbine specific I/O is specifically designed for direct interface with the unique sensors and actuators found in turbine systems. Turbines, being complex and critical components in many industrial settings, require precise and reliable control mechanisms. Turbine specific I/O modules are engineered to directly connect with these specialized devices, eliminating the need for additional interposing instrumentation.

- By eliminating the intermediate instrumentation, turbine specific I/O significantly reduces the chances of potential single point failures. This is particularly crucial in the most critical areas of turbine operation, as it improves running reliability and reduces long-term maintenance requirements. The direct interface ensures that data flows seamlessly between the I/O module and the turbine sensors and actuators, minimizing potential points of failure and streamlining the control process.

- In addition to the enhanced reliability and reduced maintenance benefits, the direct interface of turbine specific I/O modules enables advanced diagnostics. These modules can directly interrogate the connected devices on the turbine, gathering detailed data about their performance and status. This data plays a vital role in analyzing both individual device performance and overall system efficiency.

- By leveraging the direct interface and diagnostic capabilities, operators and maintenance personnel can gain valuable insights into the turbine's operation. They can monitor the health and performance of individual sensors and actuators, identifying any abnormalities or potential issues in real-time. This proactive approach facilitates timely maintenance and troubleshooting, maximizing the effectiveness of both the devices and the overall turbine system.

PRoduct Attributes

- Max Load Current:

- For 125 V dc operation, the module can handle a maximum load current of 0.4 A.

- For 48 V dc operation, the maximum load current supported is 1.2 A.

- In the case of 24 V dc operation, the module can handle a maximum load current of 3.15 A.

- For 120/240 V ac, 50/60 Hz operation, the maximum load current supported is also 3.15 A.

- Max Response Time:

- The module demonstrates a typical maximum response time of 25 ms when turning on.

- Similarly, it exhibits a typical maximum response time of 25 ms when turning off.

- Contact Material:

- The contact material used in this module is silver cad-oxide, known for its excellent electrical conductivity and resistance to corrosion.

- Input Filter:

- The module incorporates a hardware filter that effectively filters the input signals. It has a response time of 4 ms, contributing to improved signal stability and noise reduction.

- Fault Detection in I/O Board:

- The module employs various fault detection mechanisms.

- It can detect loss of contact input wetting voltage, which helps identify situations where the contact inputs are not making proper electrical contact.

- Additionally, it can detect non-responding contact inputs during the test mode, allowing for effective troubleshooting and maintenance.

- Fault Detection:

- The module employs relay position feedback utilizing a separate contact pair that is distinct from the load contacts. This arrangement enables reliable fault detection by monitoring the position of the relay.

- This feedback mechanism ensures that any deviations or abnormalities in the relay's position are promptly detected, contributing to improved system reliability and safety.

World of Controls has the most comprehensive collection of GE Mark VIe components. Please contact WOC as soon as possible if you require any extra information.

Frequently Asked Questions

What is IS230SHRSH1A?

It is a DIN-Rail Mounted I/O Module developed by GE.

What is general purpose I/O used for?

It is versatile and can be used in both turbine systems and general process control. It provides a flexible interface for connecting and controlling various sensors, switches, and actuators across different industrial processes.

What is turbine specific IO designed for?

Turbine specific is specifically designed to directly interface with the unique sensors and actuators found in turbine systems. It eliminates the need for additional interposing instrumentation, improving reliability and reducing maintenance requirements.

How does it reduce single point failures?

By directly connecting to turbine sensors and actuators, turbine specific eliminates the need for additional components, reducing potential points of failure and increasing running reliability.