World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS230SCISH2A - Simplex Contact Input Assembly Module is available in stock which ships the same day.

IS230SCISH2A - Simplex Contact Input Assembly Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS230SCISH2A - Simplex Contact Input Assembly Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

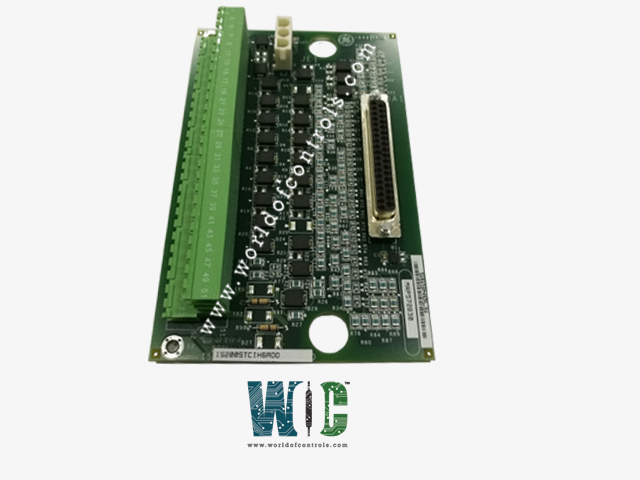

Part Number: IS230SCISH2A

Manufacturer: General Electric

Series: Mark VIe

Product Type: Simplex Contact Input Assembly Module

Number of channels: 12

Contact Resistance: 0.01 ohms

Insulation Resistance: 100 megohms

Common Mode Voltage Range: +5 V dc

Maximum Lead Resistance: 15 Ohms

Analog output current: 0-20 mA

Operating temperature: -40 to 85 °C

Dimensions: 100mm x 100mm x 1.6mm

Frequency: 50 or 60 Hz

Repair: 3-7 days

Availability: In Stock

Weight: 20 grams

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

IS230SCISH2A is a Simplex Contact Input Assembly Module manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. The Simplex Contact Input Assembly Module is an addressable device designed to monitor dry-contact inputs such as push buttons, switches, or relay contacts in fire alarm and security systems. It supports multiple wiring configurations, including Class A and Class B circuits, providing supervision for wiring faults like open circuits, short circuits, and ground faults. When a contact changes state, the module communicates the status to the main control panel, allowing real-time monitoring of system inputs. A built-in LED indicator flashes to show communication activity and stays lit when an alarm condition is detected. The module’s address is programmable, allowing it to be uniquely identified on the control loop. The board is often mounted within a larger control panel or system enclosure. Applications of the Simplex Isolated Contact Input Assembly Board can be found in various industrial settings where digital signals from sensors or devices need to be monitored or integrated into a control system. These can include applications such as monitoring limit switches, pushbuttons, proximity sensors, or other devices that provide discrete on/off signals.

INSTALLATION:

Mount the Simplex Contact Input Assembly Module in a standard MK double-gang backbox using the supplied screws and washers. Ensure the module is firmly fixed and aligned correctly. Before connecting wiring, set the device address using the internal programming port or the front programming port with a compatible Simplex programming tool such as the MX/801AP or 850EMT. Connect the wiring for the input contacts and the addressable loop terminals, observing correct polarity and adhering strictly to the wiring diagrams provided. Use wiring that complies with local regulations and standards, such as BS5839 to guarantee proper supervision of open and short circuit faults. Seal around the LED indicator and cable entry points with appropriate silicone or sealant to maintain the module’s IP22 protection rating and prevent ingress of dust or moisture.

OPERATION:

The Simplex Contact Input Assembly Module operates by continuously monitoring the state of its dry-contact inputs and the integrity of the associated wiring. It communicates with the fire alarm control panel through the addressable loop, responding to regular polling signals. During each poll, the module’s LED indicator flashes to confirm communication. When an input contact changes state, the module immediately transmits an alarm or trouble signal to the panel, depending on the type of event detected. The module supervises wiring faults such as open circuits, short circuits, and ground faults, reporting these conditions as trouble signals to ensure full supervision of both contact status and wiring integrity. The LED remains lit steadily when an active alarm condition is present.

COMPATIBILITY:

The Contact Input Assembly Module is fully compatible with Simplex addressable fire alarm systems, including MX and IDNet loop controllers and panels such as the Simplex 4008, 4010, and 4100ES series. It supports up to 250 devices per loop in IDNet systems, enabling flexible integration in both small and large-scale installations. The module adheres to relevant international standards for electromagnetic compatibility and installation safety. It fits standard mounting hardware used widely across commercial and industrial sites, ensuring straightforward integration without custom modifications.

WOC maintains the largest inventory of OEM replacement parts for GE Distributed Control Systems. We offer repair services for faulty boards as well as supply unused and refurbished boards, all backed by a warranty. Our expert team is available 24/7 to support your OEM needs and assist with any automation requirements. For pricing and availability of parts and repairs, please contact us by phone or email.

How is the module addressed in the control loop?

The address of the Simplex Contact Input Assembly Module is programmable using either the internal programming port or the front programming port. Compatible Simplex programming tools, such as the MX/801AP or 850EMT, are used to set the unique address for each module. This addressing allows the fire alarm control panel to identify and communicate with each device individually on the addressable loop.

What kind of faults does the module detect?

The module continuously supervises its input circuits and wiring for faults. It can detect open circuits (broken wires), short circuits (wires touching), ground faults (wiring connected to earth), and active alarm conditions when an input contact is activated. Upon detection of any of these conditions, the module sends corresponding trouble or alarm signals to the control panel to alert operators of the issue.

What control panels is this module compatible with?

The Contact Input Assembly Module is fully compatible with Simplex MX loop systems as well as IDNet and MAPNET II addressable fire alarm systems. It works with popular control panels like the Simplex 4008, 4010, and 4100ES series. Compatibility ensures seamless integration within a wide range of system sizes and configurations.