SPECIFICATIONS

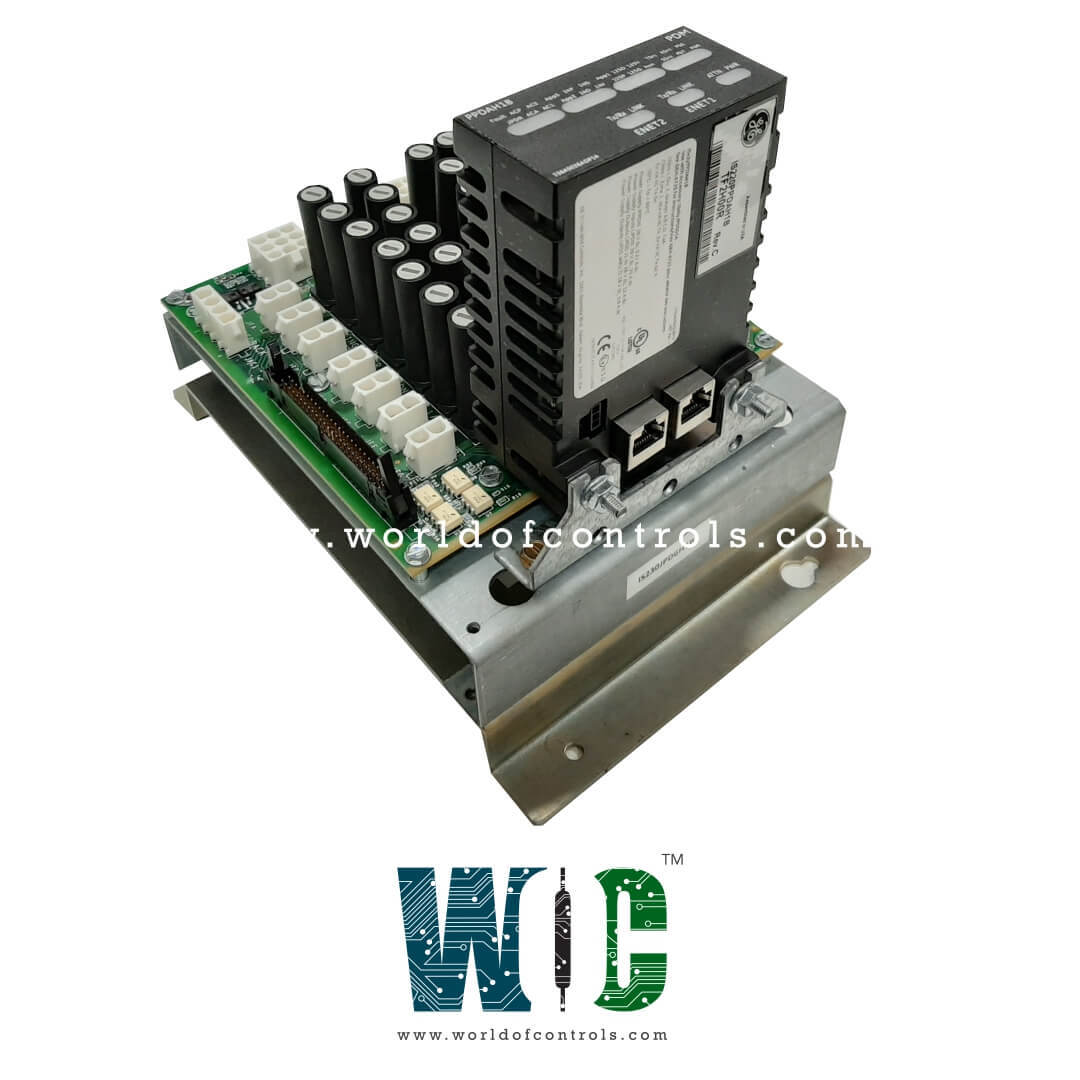

Part Number: IS230JPDGH2A

Manufacturer: General Electric

Series: Mark VIe

Product Type: Power Distribution Board

Repair: 3-5 days

Mounting: DIN-rail

Temperature: -30 to 65oC

Size: 16.51 cm High x 17.8 cm

Availability: In Stock

Country of Manufacturer: United States (USA)

Functional Description

IS230JPDGH2A is a Power Distribution Board developed by General Electrics. It is a part of Mark VIe control system. The board primarily serves as a hub for distributing power in the form of 28 V DC for control purposes within the system. This control power is essential for driving and controlling various components, enabling precise system operation. To ensure redundancy and reliability, the board is designed to accept power from two separate supply inputs through external diodes, allowing for seamless power continuity in case of a supply failure.

Features

- Integration with the PPDA I/O Pack: When coupled with the PPDA I/O pack, the board seamlessly integrates into the Power Distribution Module (PDM) system feedback loop. This integration enhances control and monitoring capabilities, allowing for real-time feedback and control adjustments as needed.

- AC Sensing Circuitry: Equipped with sensing circuitry capable of monitoring two channels of AC distribution. These channels are distributed outside the board, enabling the system to detect and respond to AC signals, further enhancing system control and safety.

- Wetting Power Distribution: In addition to control power, it also manages wetting power distribution, which can operate at either 24 V DC or 48 V DC. This versatile capability allows the board to accommodate different voltage requirements for terminal boards and other system loads. It receives DC power from two power supplies through external diodes, ensuring a redundant power source.

- Fuse Protection: For the 28 V DC outputs used for control power distribution, the board incorporates fuse protection. This safeguard helps prevent damage to the board and connected components in case of electrical faults or overloads.

- Floating DC Wetting Power Bus: It supports a floating DC wetting power bus that is centered on earth by utilizing resistors. This configuration enhances the stability and safety of the power distribution system. Additionally, it provides voltage feedback through the PPDA, allowing for the detection of system ground faults.

- Exclusion of Bulk Power Supplies: It's important to note that the board does not directly supply power to bulk 500 W - 24 V input / 28 V output power supplies that provide I/O pack control power. Instead, it focuses on control and wetting power distribution to other system components and boards.

Compatibility

- It has the capability to accommodate a Power Distribution System Feedback I/O pack, a vital component utilized in Mark VIe Control Power Distribution Modules.

- It can receive diagnostic feedback signals from as many as three other distribution boards and direct these signals to the PPDA I/O pack. Notably, due to the integration of the PPDA I/O pack onto the module itself, there is no requirement to transmit diagnostic signals from the JPDG to other power distribution boards.

Installation Procedure

- Mounting: Designed to be base-mounted in a vertical orientation, utilizing a sturdy metal bracket located within the control cabinet used by the Power Distribution Module (PDM). Secure to the bracket using four screws. These screws should be inserted into the designated mounting holes located at both the top and bottom of the module base.

- Location Consideration: While the specific location within the control cabinet is not highly critical, it is a common practice to mount distribution boards. This placement facilitates grounding and ensures a structured and organized cabinet layout.

- PPDA I/O Pack Attachment: Plug the Power Distribution System Feedback I/O pack into connector JA1 on the JPDG. Secure the PPDA I/O pack to the base using an angle bracket, and firmly fasten it in place using nuts threaded onto studs that are permanently affixed to the base for this purpose.

- Diagnostic Feedback Routing: Diagnostic feedback inputs from up to three other distribution boards can be routed. Use a 50-pin ribbon cable connected to connector P2, which is mounted on the bottom of the board, to facilitate this communication.

- Power Connections: Ensure proper power connections for the JPDG:

- For control power, connect either one or two 28 V DC control power input connections through connectors JR and JS. Features a common 28 V DC bus.

- For wetting power, connect either one or two 24 V DC wetting power input connections or one or two 48 V DC input connections through connectors JPS1 and JPS2. Features a common 24/48 V DC wetting voltage bus.

Configuration

- When jumper JP1 is inserted, the JPDG incorporates 12 kohm voltage-centering resistors. These resistors are positioned between the positive and negative direct current (dc) sources and the local earth connection. This configuration effectively centers the floating dc bus onto the earth. Conversely, removing jumper JP1 opens the connection to earth. In this state, the voltage-centering resistors are disengaged, and the floating dc bus remains uncentered with respect to earth.

- Voltage-Centering Function: JP1 enables the adjustment of the voltage-centering resistors, which is essential for ensuring that the floating dc bus aligns with the earth connection. Inserting JP1 facilitates the alignment of the floating dc bus with earth, which can be advantageous in specific operational scenarios.

- Floating DC Bus Stabilization: Insert JP1 when there is a requirement to stabilize or center a floating dc bus onto the earth connection. This configuration helps maintain stability and proper functioning of the electrical system. By removing JP1, the connection to earth is opened, providing flexibility in scenarios where a floating dc bus does not require centering on earth.

WOC has the largest stock of Speedtronic control spares. Please contact our staff by phone or email for pricing and availability on any parts and repairs

FREQUENTLY ASKED QUESTIONS

What is IS230JPDGH2A?

It is a Power Distribution Board developed by General Electrics.

What voltage options are available for wetting power distribution on the board?

The board can operate wetting power distribution at either 24 V DC or 48 V DC. This flexibility allows it to accommodate various voltage requirements for terminal boards and other system loads.

How does the board ensure redundancy in power supply for wetting power distribution?

It receives DC power from two separate power supplies through external diodes. This redundant setup ensures a continuous and reliable power source for wetting power distribution.

Could you explain the role of fuse protection on the board?

Fuse protection is essential for safeguarding the 28 V DC outputs used for control power distribution. It helps prevent damage to the board and connected components in case of electrical faults or overloads.