World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

IS2020ISUCG2A - Unit Controller Module is available in stock which ships the same day.

IS2020ISUCG2A - Unit Controller Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for IS2020ISUCG2A - Unit Controller Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

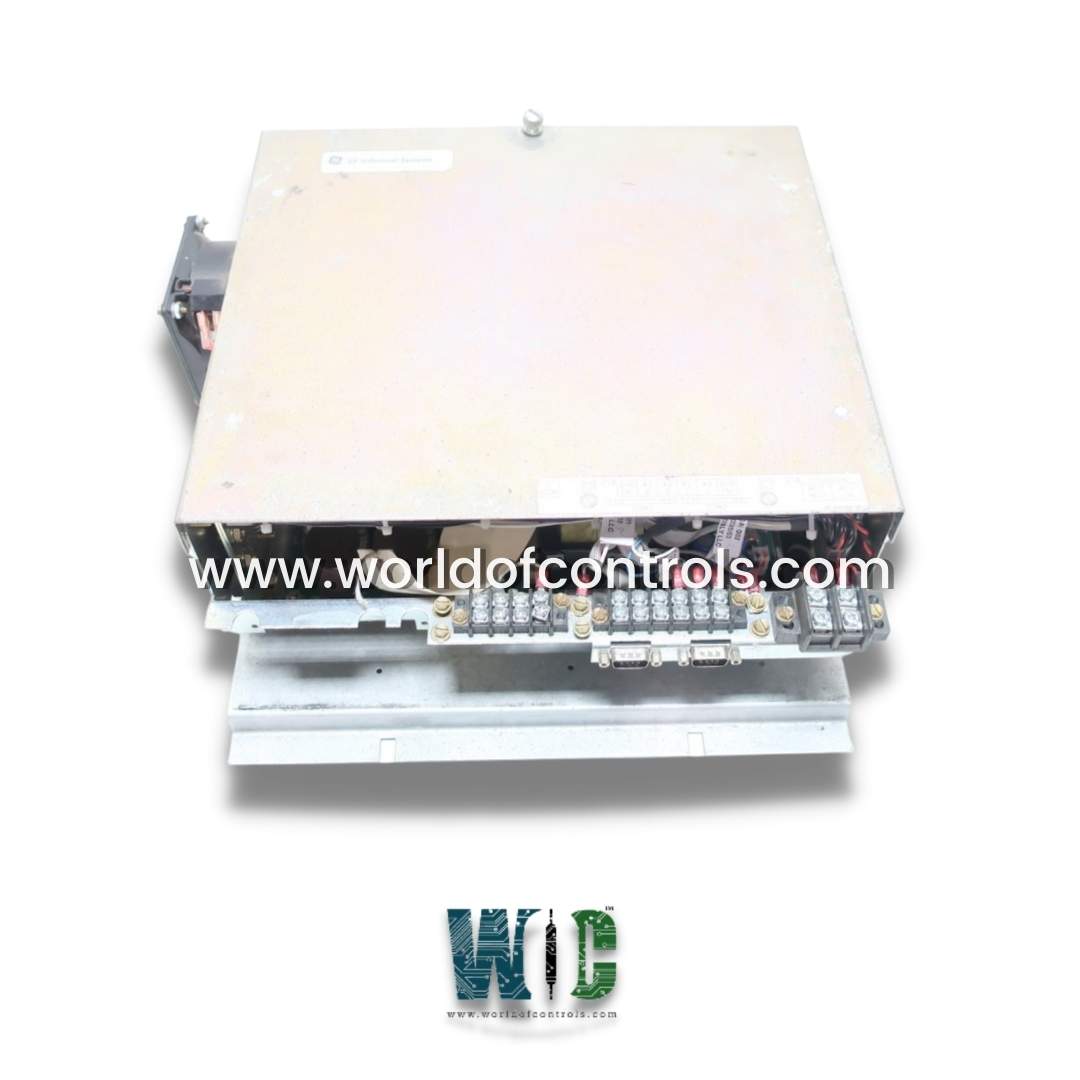

Part Number: IS2020ISUCG2A

Manufacturer: General Electric

Series: Mark VIe

Product Type: Unit Controller Module

Memory: 256 MB

Operating System: QNX Neutrino

Number of channels: 16

Programming: Boolean

Power Requirements: +5 V dc

Microprocessor: Intel Pentium M processor 1.6 GHz

Operating temperature: -25 to 70°C

Size: 33.02 cm high x 17.8 cm

Repair: 3-7 Day

Availability: In Stock

Country of Origin: United States

Manual: GEI-100599

FUNCTIONAL DESCRIPTION:

IS2020ISUCG2A is a Unit Controller Module manufactured and designed by General Electric as part of the Mark VIe Series used in GE Distributed Control Systems. The Unit Controller Module (UCM) is a key component in turbine control systems, responsible for managing and regulating the operation of turbines in various industrial applications, particularly in power generation. Here's a breakdown of its technical aspects:

FEATURES:

WOC has the largest stock of OEM replacement parts for GE Distributed Control Systems. We can also repair your faulty boards and supply unused and rebuilt boards backed up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on parts and repairs, kindly contact our team by phone or email.

What are the primary functions of a Unit Controller Module?

The primary functions of a UCM include controlling turbine start-up and shutdown sequences, regulating load demand, implementing safety protocols, detecting faults, synchronizing with the electrical grid, facilitating communication, and optimizing performance parameters.

What components are typically found in a Unit Controller Module?

A UCM consists of hardware components such as microprocessors, memory modules, input/output interfaces, communication ports, and power supplies. It also incorporates software components, including control algorithms, real-time data acquisition systems, and safety features.

How does a Unit Controller Module ensure turbine safety?

UCMs incorporate safety features such as limit switches, emergency shutdown protocols, and fault detection algorithms. These features help prevent hazardous conditions and trigger protective actions in the event of abnormalities or malfunctions.