SPECIFICATIONS

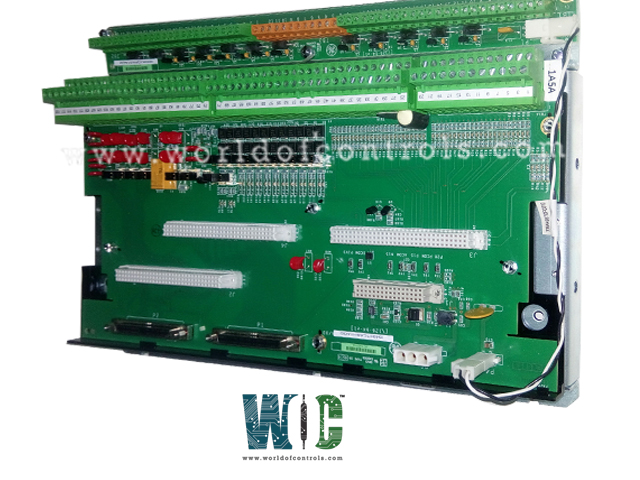

Part No.: IS400TCATH1ADC

Manufacturer: General Electric

Country of Manufacture: United States of America (USA)

Size: 33.02 cm high x 17.8 cm wide

Technology: Surface-mount

Temperature Operating: -30 to 65oC

Product Type: core analog terminal board

Availability: In Stock

Series: Mark VIe

Functional Description

IS400TCATH1ADC is a core analog terminal board developed by GE. It is a part of Mark VIe control system. The board accommodates twelve seismic inputs. These inputs are essential for monitoring vibrations and detecting ground movements, providing critical data for applications in fields such as earthquake monitoring and structural health. It supports twelve Linear Variable Differential Transformer (LVDT) inputs. LVDTs are precision sensors used to measure linear displacement, providing high accuracy and reliability in feedback for position and movement in various industrial and engineering applications.

Features

- 4-20 mA Inputs: The terminal board includes twenty-four 4-20 mA inputs, which are standard in industrial signal transmission. These inputs handle a range of sensor data for processes such as temperature, pressure, and flow rate monitoring.

- Magnetic Pulse Rate Inputs: The board also provides two magnetic pulse rate inputs, which are used for measuring the speed of rotating machinery by detecting magnetic pulses generated by rotating elements.

- Signal Distribution: The input signals received are fanned out to one or up to three PCAA modules. This distribution capability ensures that multiple modules can process the same input data, enhancing the system's flexibility and redundancy.

- Power Supply: An individual 24 V dc power source is provided specifically for the twenty-four 4-20 mA inputs. This power supply is divided between the board and an adjacent JGPA board, with half of the inputs powered by each board. This setup ensures a stable and reliable power supply for all 4-20 mA inputs, critical for maintaining accurate signal integrity.

- Output Capabilities: The TCAT board produces three 4-20 mA voted signals as outputs. Voted signals are typically used in systems where safety and reliability are paramount. They involve comparing multiple input signals and producing a consensus output, thus ensuring that the output is robust and less prone to errors from any single faulty input.

- Enhanced Monitoring and Control: By providing a wide range of input options and distributing signals to multiple PCAA modules, the terminal board enhances the monitoring and control capabilities of industrial systems. It allows for comprehensive data collection from various sensors and ensures that this data is reliably processed and utilized.

- Flexibility and Redundancy: The ability to fan out inputs to multiple modules adds a layer of redundancy, improving system reliability. If one module fails, others can continue processing the signals, minimizing downtime and maintaining continuous operation.

- Robust Power Management: The dedicated 24 V dc power supply for the 4-20 mA inputs ensures that these signals remain accurate and reliable. By splitting the power supply between the TCAT and JGPA boards, the system maintains consistent performance even if one power source experiences issues.

- High Precision Outputs: The 4-20 mA voted signals provided by the board ensure that the outputs are accurate and reliable, critical for applications that require precise control and monitoring, such as in safety systems and high-stakes industrial processes.

Wiring

- Terminal Connections: The terminal board features 120 pluggable Euro-style box terminals. These terminals are known for their robust design and ease of use, making them ideal for industrial applications where secure and reliable connections are paramount. The pluggable design allows for easy installation and removal, which simplifies maintenance and upgrades.

- Adjacent JGPA Board: A JGPA board is mounted adjacent to the TCAT terminal board, complementing the wiring capabilities of the TCAT board. The JGPA board also uses Euro-style box terminals to maintain consistency and reliability in the wiring system.

- Shield Termination: The JGPA board provides forty-eight shield termination points. Shielding is crucial in industrial environments to protect signal integrity by minimizing electromagnetic interference (EMI) and ensuring accurate data transmission.

These shield termination points are designed to securely terminate the shields of signal cables, thus enhancing the overall electromagnetic compatibility (EMC) of the system.

- Power Supply for Transmitters: The board includes twelve 24 V dc output terminals specifically for powering 4-20 mA transmitters. This dedicated power supply ensures that all 4-20 mA signals are powered consistently and reliably. The 24 V dc output terminals provide a stable power source for the transmitters, which are widely used in industrial automation for transmitting analog signals representing various process variables like temperature, pressure, and flow.

- Ease of Installation and Maintenance: The use of pluggable Euro-style box terminals simplifies both the installation and maintenance processes. These terminals allow for quick connection and disconnection of wires, reducing downtime during maintenance and facilitating easy upgrades or replacements.

- Enhanced Signal Integrity: The provision of shield termination points on the JGPA board significantly enhances signal integrity by reducing the impact of EMI. This is particularly important in environments with high electrical noise, where maintaining accurate signal transmission is critical.

- Reliable Power Distribution: By including dedicated 24 V dc output terminals for 4-20 mA transmitters, the wiring system ensures a reliable and stable power supply to these critical components. This stability is essential for maintaining accurate and consistent signal transmission from the transmitters to the monitoring and control systems.

- System Integration and Expansion: The adjacency of the JGPA board to the TCAT terminal board and the use of consistent terminal types facilitate seamless integration and expansion of the system. This modular approach allows for easy addition of new components or scaling up the system to meet increasing demands.

Operation

- Signal Fanning: The primary function of the terminal board is to provide fanning of input signals to one or more PCAA modules. This means that the signals received from various sensors and input devices are distributed, or fanned out, to multiple PCAA modules. This distribution is achieved using high-reliability passive circuits. These circuits ensure that the input signals are accurately and reliably delivered to the PCAA modules, which is crucial for maintaining system integrity and performance, especially in applications requiring redundancy. By distributing the signals to multiple modules, the board helps prevent single points of failure, thereby enhancing the overall reliability of the system.

- Power Management: The TCAT terminal board is designed to accept 28 V dc power from the connected PCAA modules. To ensure redundancy and reliability in power supply, the TCAT board performs a diode-or of the power sources. This technique involves combining multiple power inputs using diodes, which allows the board to obtain a redundant power input for the 24 V dc outputs. This method ensures that if one power source fails, the other can continue to supply power, thereby maintaining continuous operation of the system. Each of the 24 V dc outputs is equipped with an individual voltage regulator. These regulators are critical for ensuring that the voltage supplied to the connected devices is stable and within the required specifications. The voltage regulators also feature thermal shutdown capabilities, which provide branch circuit protection. Thermal shutdown protects the circuits from overheating, which can occur due to excessive current or environmental conditions. This feature enhances the safety and durability of the TCAT board by preventing damage to the circuits and connected devices.

- Redundancy and Reliability: The integration of these power management features into the terminal board significantly boosts its reliability in redundant applications. The use of diode-or power sources ensures that there is always a backup power supply available, minimizing the risk of power failure. The individual voltage regulators with thermal shutdown provide an additional layer of protection, ensuring that each output remains stable and protected from potential thermal damage. y incorporating high-reliability passive circuits for signal fanning and robust power management techniques, the TCAT terminal board is well-suited for use in critical applications where system uptime and reliability are paramount. These features collectively ensure that the TCAT board can reliably distribute input signals and maintain stable power supply, thereby supporting the overall functionality and reliability of the PCAA modules and the broader system they are a part of.

The WOC team is always available to help you with your Mark VIe requirements. For more information, please contact WOC.

Frequently Asked Questions

What is IS400TCATH1ADC?

It is a core analog terminal board developed by GE under the Mark VIe series.

How is the terminal board mounted?

The board mounts using an insulating plastic carrier on a metal back base. Three screws secure it one at the top, one at the bottom of the field terminals, and one in the center of the board.

What are the mounting screws for?

Mounting screws secure the board firmly in place within its housing or enclosure, preventing movement during operation and ensuring stable electrical connections.

Why is secure mounting important?

Secure mounting prevents damage to components, maintains stable electrical connections, and promotes the overall reliability and longevity of the terminal board and the system it's a part of.