World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

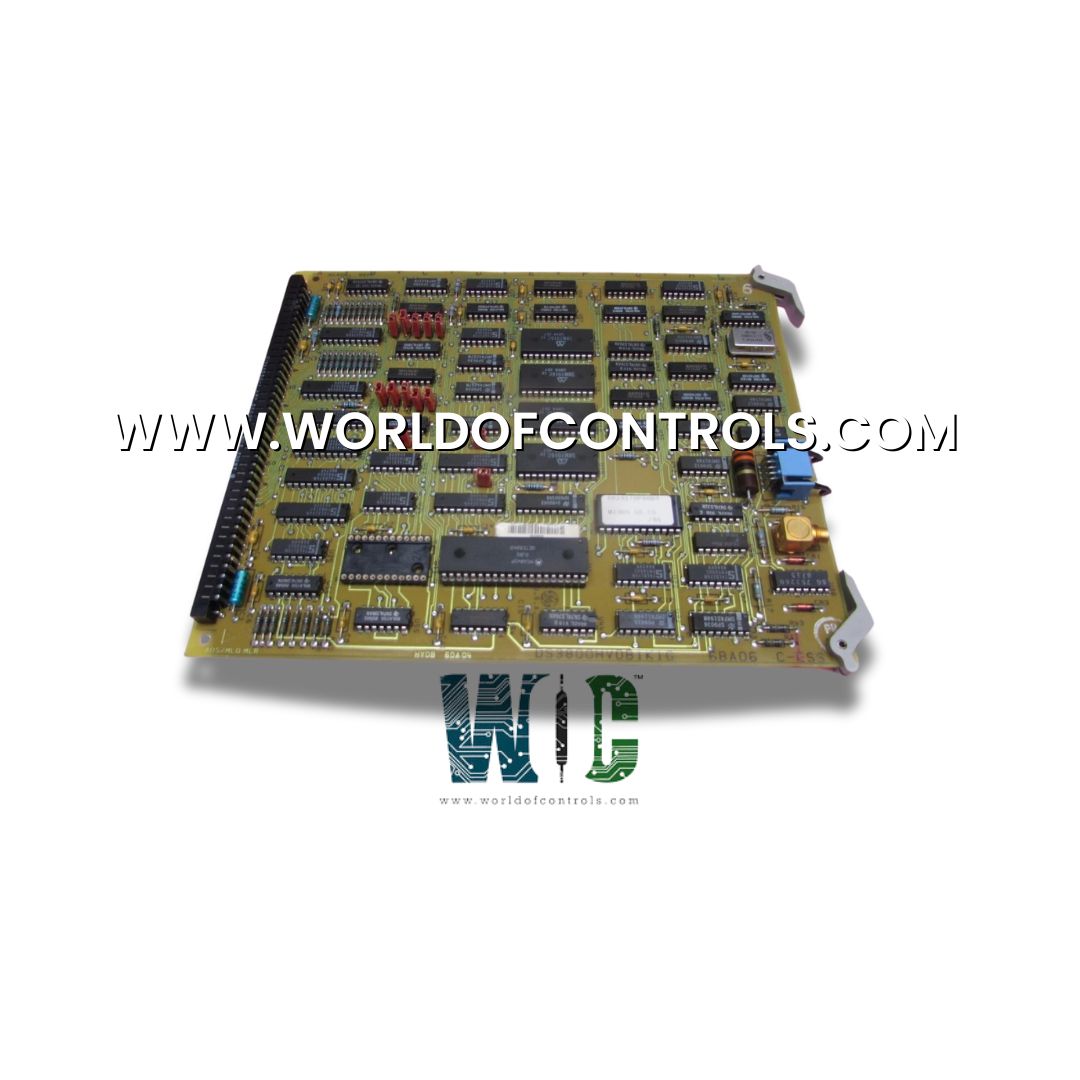

DS4815CHGA - Video Driver Board is available in stock which ships the same day.

DS4815CHGA - Video Driver Board comes in UNUSED as well as REBUILT condition.

To avail our best deals for DS4815CHGA - Video Driver Board, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: DS4815CHGA

Manufacturer: General Electric

Series: Mark IV

Product Type: Video Driver Board

Power Requirements: +5 V dc

Power supply voltage: 28 V DC

Operating temperature: -35 to +55°C

Size: 15.7 cm high x 17.5 cm

Weight: 0.5kg

Repair: 3-7 days

Availability: In Stock

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

DS4815CHGA is a Video Driver Board manufactured and designed by General Electric as part of the Mark IV Series used in GE Speedtronic Gas Turbine Control Systems. A video driver board, also known as a display driver board, is an essential component in electronic display systems. It acts as an intermediary between the main processing unit (like a computer or a mobile device) and the display panel, converting and managing signals to ensure proper display of visual information. Below is an overview of the functions, key components, types, applications, and considerations for a video driver board:

FUNCTIONS OF A VIDEO DRIVER BOARD:

Signal Processing: A video driver board converts incoming digital video signals (such as RGB, YCbCr, LVDS, or eDP) from the main processing unit (like a GPU or controller) into formats compatible with the specific display panel, including TFT LCD, OLED, or LED. This process may involve analog-to-digital or digital-to-digital conversion (e.g., HDMI to LVDS), and includes essential data formatting tasks such as bit-depth adjustment, pixel reordering, and resolution scaling (upscaling or downscaling) to ensure proper image rendering on the display. Synchronization functions align the timing of horizontal and vertical sync signals with the display’s refresh rate and resolution, preventing flicker, tearing, and display artifacts by ensuring accurate frame timing and consistent signal delivery.

Power Management: The power management system of a video driver board is responsible for delivering stable and precise power to various display components. Voltage regulation circuits convert input power into required voltage levels such as 3.3V, 1.8V, or 12V, ensuring safe and efficient operation of the display panel, backlight, and driver ICs. Current control mechanisms monitor and limit current flow to protect sensitive components like backlight LEDs, maintaining consistent brightness and preventing thermal overload. These functions work together to enhance reliability, extend the lifespan of the display, and support energy-efficient performance.

Control Signals: Control signal management in a video driver board governs various display characteristics to optimize image quality and usability. Backlight control regulates the brightness of LCD panels through pulse-width modulation (PWM) or analog dimming, often adapting dynamically based on ambient light or content. Gamma correction circuitry adjusts the luminance levels of pixel outputs to correct non-linear behavior in displays, ensuring accurate color reproduction and balanced contrast across all brightness levels. These control signals contribute significantly to visual clarity, viewing comfort, and compliance with display standards.

Interface Management: Interface management handles the seamless communication between input sources and the display panel. Input ports such as HDMI, VGA, DVI, DisplayPort, or USB-C receive video signals from external devices like computers, media players, or embedded systems. The board processes and converts these signals, when necessary, to match the panel’s required format. Output ports then deliver the refined signal to the display using standards like LVDS, eDP, or MIPI DSI. These interfaces ensure compatibility, support plug-and-play functionality, and maintain signal integrity through equalization, buffering, and protection features.

WOC has the largest stock of GE Speedtronic Control System Replacement Parts. We can also supply unused and rebuilt backup with a warranty. Our team of experts is available around the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

Why is a video driver card essential in a control system?

In modern control systems, graphical user interfaces (GUIs) have become essential for operators to monitor the system's status, analyze data trends, and make critical decisions. A video driver card is crucial because it accelerates graphical processing, improves display performance, and enhances the overall user experience.

How does a video driver card contribute to Human-Machine Interface (HMI) design in control systems?

The video driver card enables the creation of high-quality and responsive graphical interfaces, improving the operator's ability to interact with the control system. It provides real-time updates, alarms, and displays critical information visually, making it easier for operators to understand the system's status and respond effectively.

What benefits does a video driver card offer for remote monitoring in control systems?

When control systems are monitored or controlled remotely, a video driver card allows for high-quality video streaming and graphical representations of the system's operation. This feature enables remote operators to monitor the control system in real time, even from a considerable distance.