World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

9905-708 - Digital Synchronizer Module is available in stock which ships the same day.

9905-708 - Digital Synchronizer Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for 9905-708 - Digital Synchronizer Module, contact us and we will get back to you within 24 hours.

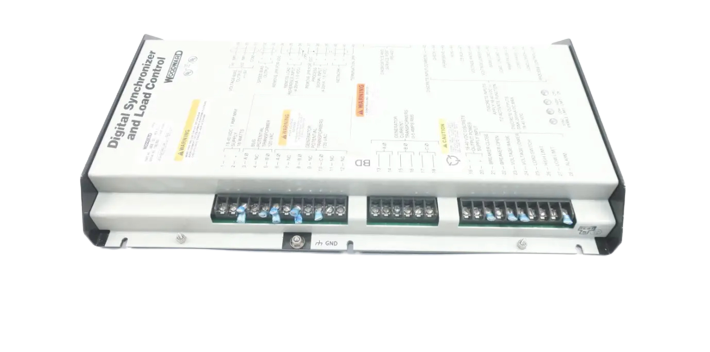

Part Number: 9905-708

Manufacturer: Woodward

Product type: Digital Speed Matching Synchronizer Module

Availability: In Stock

Country of Manufacture: United States (USA)

9905-708 is a Digital Synchronizer and Load Control Module developed by Woodward. The module is specifically designed for digital synchronization and load control applications, enabling seamless integration into systems. It plays a vital role in synchronizing multiple generators and aligning their frequencies and voltages before connecting them to the grid. This synchronization process ensures a smooth and stable transfer of power, minimizing disturbances and potential damage to the connected equipment.

World of Controls has the most comprehensive selection of GE and Woodward components. Our professionals are available to help you with your requirements at any time. If you require any additional information, please contact WOC immediately.

What is 9905-708?

It is a Digital Synchronizer Module developed by Woodward.

What are the recommended ambient temperature limits for the system location?

The ambient temperature of the system location should not be below 0 or above 55 degrees Celsius.

Is there a recommended limit for relative humidity?

Yes, the relative humidity should not be greater than 90%, and it should be non-condensing.

How should ventilation be provided for the units?

Adequate ventilation should be provided to allow the units to cool. It is also recommended to shield the units from heat if they are mounted near heat-producing devices.

What is the recommended air gap above and below the chassis?

An 8 cm air gap above and below the chassis is recommended for proper airflow.

What is the requirement for chassis mounting screws to ensure EMC compliance?

To ensure EMC compliance, all chassis mounting screws (8-32 M4) must be installed to properly ground the chassis to the mounting plate.