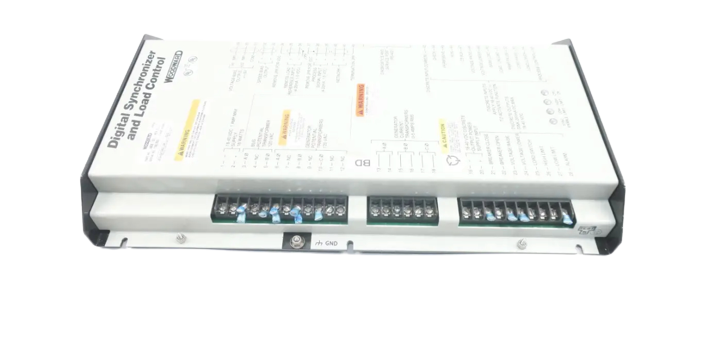

SPECIFICATIONS

Part Number: 9905-707

Manufacturer: Woodward

Input Voltage: 120Vac

Operating Temperature: -40 to 158 F

Standards: 1�5 Vdc Speed Bias

Storage Temperature: -67 to 221 F

Size: 460.65mm x 264.16mm x 58.42mm

Product Type: Module

Availability: In Stock

Function: Digital Synchronizer and Load Control

Country of Manufacture: United States (USA)

Functional Description

9905-707 is a Digital Synchronizer and Load Control developed by Woodward. In the realm of advanced control systems, the Woodward series of microprocessor-based Digital Synchronizer and Load Controls stands as a testament to precision engineering and sophisticated functionality. Among its ranks, it emerges as a reduced upgrade level model, yet one that is equally distinguished in its role within the series. This unit serves as a pivotal component in the parallel operation, synchronization, as well as the loading and unloading of three-phase AC generator sets. It's worth noting that while it does not incorporate power factor control or process control functions, its core capabilities are designed to optimize performance and operational efficiency.

Capabilities

- DSLC boasts a set of specifications that underscore its robustness and adaptability.

- Operating with an input voltage rating of 120 Vac and a speed bias ranging from 1 to 5 Vdc, this control unit thrives within dynamic operational scenarios.

- Its Open Delta PT Configuration enables it to function across a remarkable spectrum of temperatures, with an operational range extending from -40 to +70 �C (-40 to 158 F), and storage capacities spanning from -67 to 221 F.

Features

- Built-in Diagnostics: Equipped with advanced diagnostic capabilities, this unit ensures operational transparency by facilitating real-time monitoring and proactive issue identification.

- Handheld Programmer Terminal: The control system's setup, metering, and diagnostics are conveniently accessible through a handheld programmer terminal, enhancing the ease of operation and system management.

- Automatic Generator Loading and Unloading: The control unit adeptly manages the loading and unloading of generator sets, optimizing their performance and aligning power generation with demand.

- Load Control Capabilities: The unit is equipped with the intelligence to execute droop, baseload, and isochronous load control, allowing for a tailored approach to power distribution and synchronization.

- Reverse Power Relay: Ensuring operational safety, the unit features a reverse power relay that acts as a protective barrier against potential power flow deviations.

Advanced Synchronization Techniques

- Offers two distinct synchronization methods: phase matching and slip frequency synchronizing.

- Both methods leverage actual slip frequency and breaker delay values to anticipate the optimal phase difference between the generator and the bus during breaker closure. This predictive approach enhances synchronization accuracy and minimizes potential disruptions during the process.

Automatic Dead-Bus Closure

- Automatic dead-bus closure function.

- This mechanism permits only one unit to initiate dead-bus closure, employing locking techniques over the communications network. This not only ensures operational integrity but also enhances system safety during critical phases.

Characteristics

- Reduces wiring between the automatic loading controls, the load control, and the synchronizer.

- The necessity for redundant sensors (such PTs, CTs, and MOPs) that connect to separate modules like the load sensor and synchronizer is removed by having functionalities combined into a single box.

- By enabling the user to configure the control before the system is turned on, hand-held programming shortens the installation and calibration times.

- During installation and troubleshooting, an operator can monitor generator characteristics, contact switches, and analog I/O.

- Digital communications across the LON reduce susceptibility to noise on the load-sharing lines

Operating Modes

- ISOLATED BUS: The LON is used by the DSLC to communicate and share proportional real and reactive loads. Reactive loads (kVAR) are shared by matched power factors, and real loads (kW) are regulated using percentages of full loads for each machine. The DSLC control balances loads while maintaining a specific bus voltage and frequency.

- UTILITY PARALLEL: The control gauges the generator's actual load (kW) and modifies the speed control to meet a predetermined base load or regulates a process at a user-selected, externally adjustable set-point. With an MSLC, it can be set to a constant import/export level ( Master Synchronizer and Load Control). The DSLC control can additionally monitor and preserve a predetermined power factor or a specified reactive load.

- TRANSITION BETWEEN MODES: The component will transition between modes at a user-selected rate until it is within 5% of its objective. Afterward, it switches to dynamic control, allowing changes in an operating mode without any bumps. Also, once the real load mode is changed to or from an isolated load-sharing application, the DSLC control automatically switches to VAR/PF mode.

World of Controls has the most comprehensive selection of GE and Woodward components. Our professionals are available to help you with your requirements at any time. If you require any additional information, please contact WOC immediately.

Frequently Asked Questions

What is 9905-707?

It is a Digital Synchronizer and Load Control developed by Woodward.

What functions can the DSLC perform in generator set operations?

It excels in multiple functions relevant to generator set operations, including paralleling multiple generator sets, synchronizing their outputs, and managing loading and unloading operations.

Can the component control power factor or process functions?

DSLC does not include power factor control or process control functions. Its focus is primarily on synchronizing and load management aspects of generator set operations.

How does the DSLC contribute to operational efficiency?

By excelling in paralleling, synchronizing, loading, and unloading tasks, enhances the operational efficiency of three-phase AC generator sets, ensuring optimal power distribution and synchronization.