World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

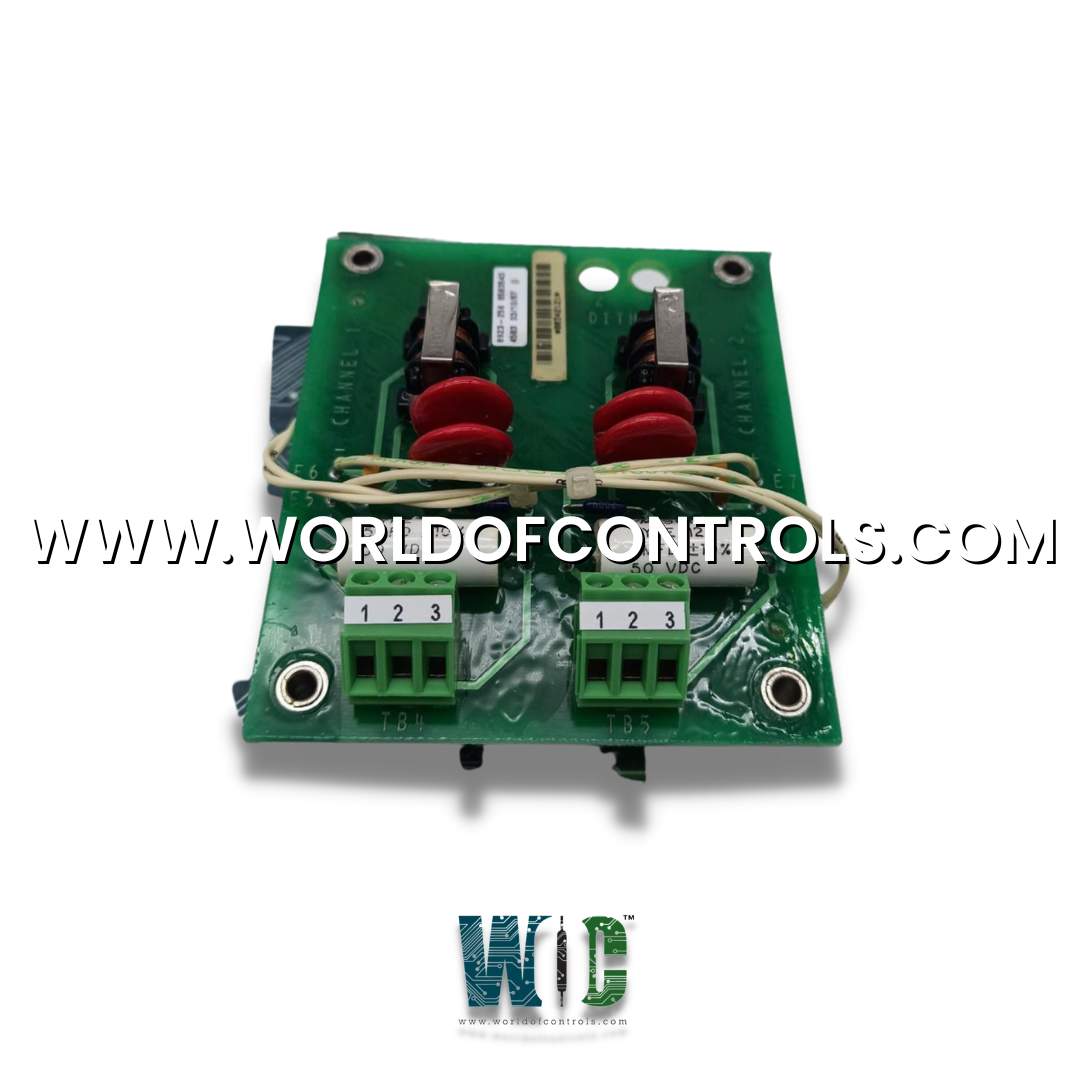

8923-256 - Channel I/O Module is available in stock which ships the same day.

8923-256 - Channel I/O Module comes in UNUSED as well as REBUILT condition.

To avail our best deals for 8923-256 - Channel I/O Module, contact us and we will get back to you within 24 hours.

SPECIFICATIONS:

Part Number: 8923-256

Manufacturer: Woodward

Product Type: Channel I/O Module

Size: 305 H x 356 W x 152 D mm

Discrete Outputs: 12 relay outputs

Operating Temperature: 0 - 40 degrees C

Current Draw: 12 VDC at 650 mA

Repair: 3-7 Day

Availability: In Stock

Weight: 1.82 kg

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

8923-256 is a Channel I/O Module manufactured and designed by Woodward used in Gas Turbine Control Systems. Channel I/O module plays a crucial role in facilitating communication between the control system and various components of the turbine. Turbines, whether used for power generation or other industrial processes, often involve complex control systems to monitor and manage their operation.

FEATURES:

Data Exchange:

Control Signals:

Fault Monitoring and Diagnostics:

Communication with External Systems:

Safety Systems Integration:

Real-time Processing:

WOC has the largest stock of Woodward Turbine Control System Replacement Parts. We can also repair your faulty boards. We can also supply unused and rebuilt backed-up with a warranty. Our team of experts is available round the clock to support your OEM needs. Our team of experts at WOC is happy to assist you with any of your automation requirements. For pricing and availability on any parts and repairs, kindly get in touch with our team by phone or email.

What is a Channel I/O Module in the context of industrial systems?

A Channel I/O (Input/Output) Module is a component that facilitates communication between a control system and external devices or channels in industrial settings. It manages the exchange of data, control signals, and information between the control system and various sensors, actuators, and other peripherals.

How does a Channel I/O Module contribute to the efficiency of a turbine control system?

The Channel I/O Module enables the turbine control system to receive real-time data from sensors, send control signals to actuators, and respond quickly to changes in operating conditions. This contributes to the overall efficiency and reliability of the turbine by facilitating timely adjustments and ensuring optimal performance.

How does a Channel I/O Module handle communication between the control system and external systems or central control rooms?

The Channel I/O Module manages the communication protocols between the control system and external devices or central control rooms. It ensures the secure and efficient exchange of information, allowing for coordination and monitoring of the industrial process on a broader scale.