SPECIFICATIONS

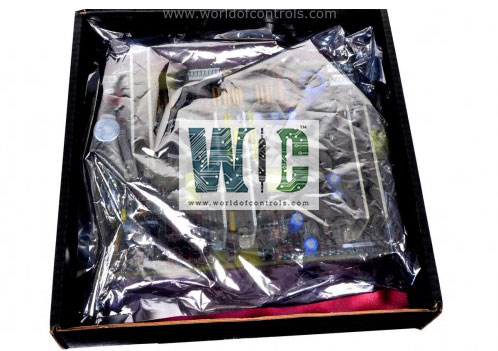

Part Number: 5466-041

Manufacturer: Woodward

Product type: EM35 Driver Card

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

5466-041 is a EM35 Driver Card developed by Woodward. EM-35 driver serves as an electric actuator driver exclusively crafted for three-phase, brushless DC motors. This versatile driver finds its role in powering rotary fuel metering valves, contributing to seamless operational efficiency. Catering primarily to applications demanding high accuracy and dynamic performance, the EM-35 digital driver finds its niche in dry low emissions (DLE) systems and similar scenarios. Encased within a robust sheet metal enclosure, the EM-35 digital driver boasts a watertight and corrosion-resistant design. This protective housing ensures the durability and reliability of the driver, safeguarding its internal components from environmental factors that might otherwise compromise its functionality. Whether orchestrating intricate movements in DLE systems or driving precision-driven applications, the EM-35 driver exemplifies a fusion of precision, adaptability, and rugged construction.

Operation

- The EM-35 digital driver system encompasses a duo of integral components: the position controller module and the driver unit. Nestled within the NetCon system control, the position controller module houses a digital position controller that deftly interprets a demand signal from the system's CPU, as well as redundant feedback signals sourced from a resolver/digital converter situated within the remote driver.

- This meticulously orchestrated exchange of signals ensures precise control. The outcome of the position controller's calculations is channeled to a brushless DC motor driver within the remote driver, fostering optimal motor function. Communication between the position controller module and the digital driver is orchestrated through serial communication lines, with the data being represented in a digital format to uphold the essential 16-bit feedback resolution, pivotal for adhering to stringent system accuracy prerequisites.

- Distinctly operating outside the realm of the system processor, the digital position controller housed within the position controller module expertly closes a position loop. This autonomous control loop is navigated by a 16-bit demand signal transmitted via the VME bus, its timing intricacies synchronized with the operating rate group of the IACT_EM MOE block.

- Periodically, every 1.66 milliseconds, a 16-bit position feedback signal emanates from the remote driver's R/D converter, engaging in a comparative dance with the demand signal. The disparity between these signals becomes the focus of a digital control algorithm that processes and manages this difference. The position controller module adeptly monitors both feedback signals, tactically selecting the optimal one for use in the control algorithm, all while effectively communicating any detected discrepancies or errors inherent in the feedback signals.

Shielded Wiring

- Shielded cables within the system must adhere to specific construction guidelines: they should employ twisted conductors alongside either a foil or a braided shield, ensuring that the cable's capacitance rating does not surpass 164 pF/m (50 pF/ft). Shielding of all signal lines is paramount to prevent the unintended reception of extraneous signals from neighboring equipment. The designated connection methodology, as depicted in the Plant Wiring Diagram (refer to Figures 2-2 and 2-3), should be meticulously followed.

- To preserve the integrity of the setup, any exposed wire extending beyond the shield is restricted to a maximum length of two inches. At the opposite end of the shield, it's imperative to leave it open and insulated from contact with any other conductor. A crucial precaution to observe is the separation of shielded signal wires from other cables carrying substantial currents; running them together could compromise signal quality and induce interference. These guidelines collectively ensure an environment conducive to optimal signal transmission and minimize the risk of signal degradation or interference.

World of Controls has the most comprehensive selection of GE and Woodward components. Our professionals are available to help you with your requirements at any time. If you require any additional information, please contact WOC immediately.

Frequently Asked Questions

What is 5466-041?

It is a EM35 Driver Card developed by Woodward.

What types of systems is the EM-35 driver suitable for?

It is well-suited for systems with rotary fuel metering valves, especially in dry low emissions (DLE) systems. Additionally, its adaptability makes it a valuable component for applications requiring precision and efficiency.

How does the driver contribute to operational efficiency?

By effectively controlling three-phase, brushless DC motors and powering rotary fuel metering valves, the component enhances the efficiency of the systems it's integrated into. Its high accuracy and dynamic performance further contribute to seamless and optimized operations.

Can it handle demanding operational environments?

Yes, the driver is designed to withstand demanding operational environments. Its robust construction and protective enclosure ensure that it can operate reliably even in challenging conditions.