SPECIFICATIONS

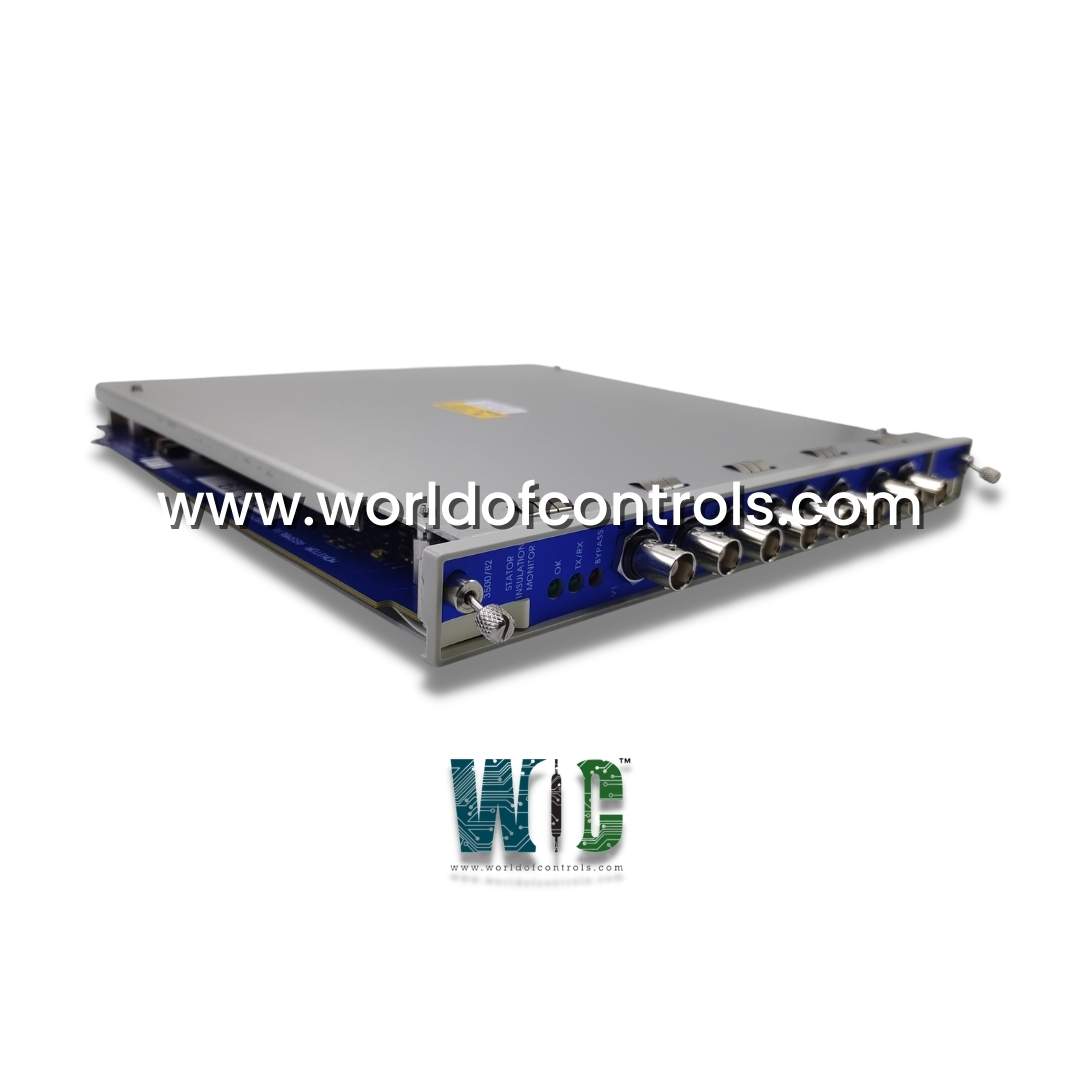

Part Number: 3500/82

Manufacturer: Bently Nevada

Series: 3500

Product type: Stator Insulation Monitoring System

Dimensions (Height x Width x Depth): 241.3 mm x 24.4 mm x 241.8 mm

Weight: 0.97 kg

Availability: In Stock

Country of Manufacture: United States (USA)

Functional Description

3500/82 is a stator insulation monitoring system developed by Bently Nevada. The Bently Nevada Stator Insulation Monitoring System measures the leakage current of motors up to 7.5 kV and 1000 Amps using cutting-edge technology. The measurements are taken while the motor is running, and the system uses the measured data to determine the condition of the stator insulation in the motor in real time. The 3500/82 can be configured to perform the following functions using the 3500 Rack Configuration Software:

- Display the motor's instantaneous stator leakage current on each phase.

- Show compensated dissipation factor and dissipation factor change from a given reference point.

- Display the temperature of the motor stator and the average temperature.

- Display data values for line voltage and frequency.

- Retrieve historical data from the monitor for data analysis.

- Set annunciation alarm levels.

- Configure the temperature range and time period for temperature learning, as well as view the current learning state.

- View the number of temperature samples versus operating temperatures that are used to create the learning curve for temperature compensation.

Features

- The system consists of a 9-channel monitor that accepts inputs from the High Sensitivity Current Transformer (HSCT), High Voltage Sensors (HVS), and 4-20 mA process signals corresponding to motor temperature measurements. The system processed data and results can be displayed on the 3500-94 Display.

- From stator RTD temperature measurements, the system can accept three HSCT, three HVS, and three 4-20mA process inputs. Because the interface modules can drive long field cables, the monitor can be placed in a control or instrumentation room up to 330 meters (1,000 feet) from the motor or interface modules.

- The component includes measurement trending, which compares current measurements to any historical data taken in the last ten years (if the historical data is available). The time window for comparison can be set by the user.

Functional Description

- Show the motor's instantaneous stator leakage current on each phase.

- Show the compensated dissipation factor as well as the change in dissipation factor from a given reference point.

- Display the temperature of the motor stator as well as the average temperature.

- Display line voltage and frequency data values.

- Retrieve historical data from the monitor for data analysis.

- Set annunciation alarm levels.

- Configure the temperature range and time period for temperature learning, as well as the learn and extend modes, and view the current learning state.

- View the number of temperature samples vs. operating temperatures that are used to create the temperature compensation learning curve.

Front Panel LEDS

- OK LED: Indicates that the system is in good working order.

- When the 3500/82 is communicating with other modules in the 3500 rack, the TX/RX LED illuminates.

- Bypass LED: This light indicates that the 3500/82 is in bypass mode.

Alarm Setpoints

- The user can set Alert levels for each value measured by the monitor and Alarm setpoints for any value measured by the monitor using software configuration.

- For each measured value, alarms can be set from 0 to 100% of full-scale.

WOC is happy to assist you with any of your Bently Nevada requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

FREQUENTLY ASKED QUESTIONS

What is 3500/82?

It is a stator insulation monitoring system developed by Bently Nevada.

What inputs does the 9-channel monitor accept?

The monitor accepts inputs from the High Sensitivity Current Transformer (HSCT), High Voltage Sensors (HVS), and 4-20 mA process signals corresponding to motor temperature measurements.

How can the system processed data and results be displayed?

The data and results can be displayed on the 3500-94 Display.

How many HSCT, HVS, and 4-20mA process inputs can the system accept?

From stator RTD temperature measurements, the system can accept three HSCT, three HVS, and three 4-20mA process inputs.

Can the monitor be placed far away from the motor or interface modules?

Yes, the interface modules can drive long field cables, and the monitor can be placed in a control or instrumentation room up to 330 meters (1,000 feet) from the motor or interface modules.