World Of Controls understands the criticality of your requirement and works towards reducing the lead time as much as possible.

3500/62 - Process Variable Monitor is available in stock which ships the same day.

3500/62 - Process Variable Monitor comes in UNUSED as well as REBUILT condition.

To avail our best deals for 3500/62 - Process Variable Monitor, contact us and we will get back to you within 24 hours.

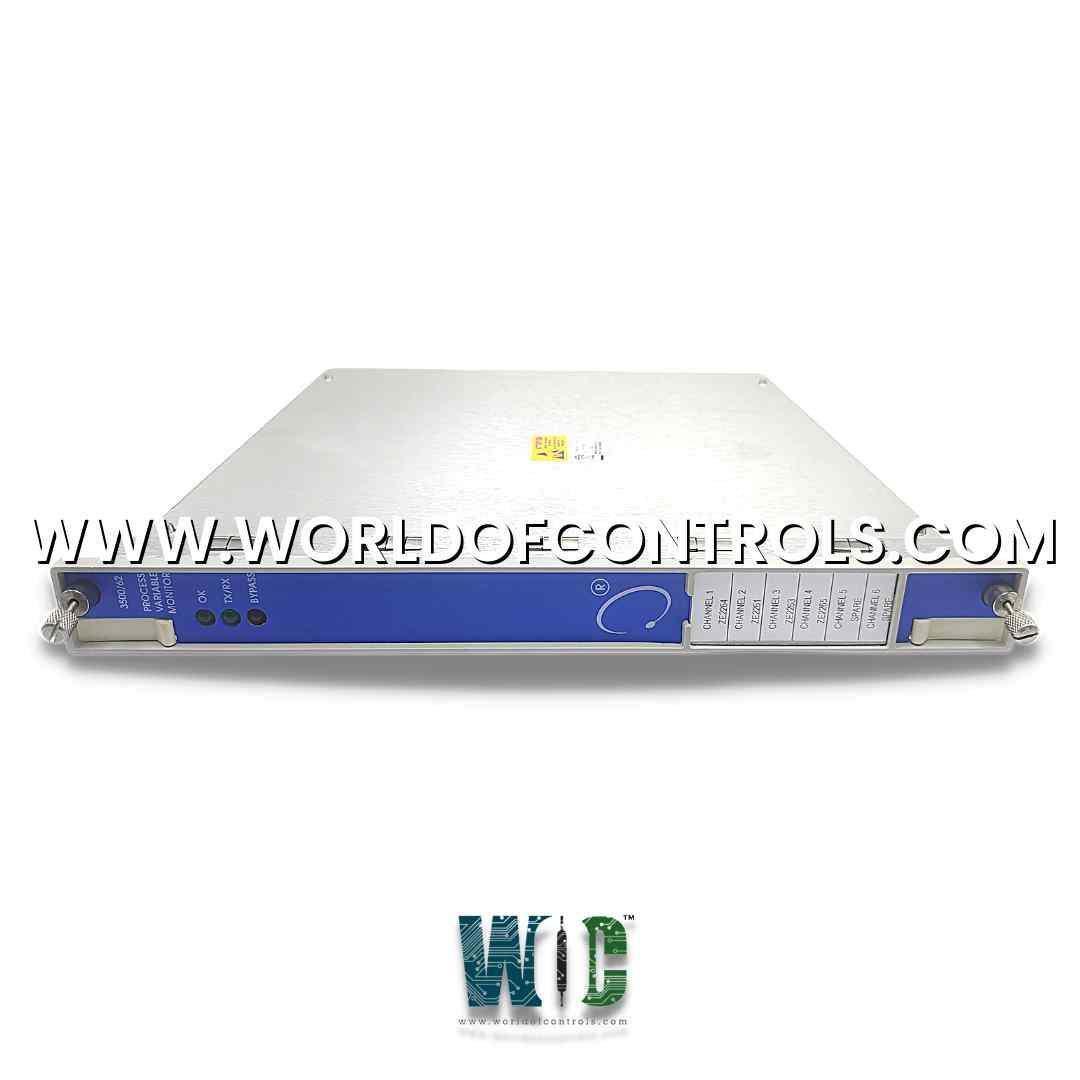

Part Number: 3500/62

Manufacturer: Bently Nevada

Series: 3500

Product type: Process Variable Monitor

Dimensions (height xwidthxdepth): 241.3 mmx 24.4 mmx 241.8 mm

Weight 0.82 kg (1.8 lbm)

Power Consumption:7.0 watts, typical

Availability: In Stock

Country of Manufacture: United States (USA)

3500/62 is a process variable monitor designed and developed by Bently Nevada. The Process Variable Monitor is a 6-channel monitor for processing machine critical parameters such as pressures, flows, temperatures, and levels that require continuous monitoring. The monitor accepts current inputs ranging from +4 to +20 mA as well as proportional voltage inputs ranging from -10 to +10 Vdc. It conditions these signals before comparing them to user-programmable alarm setpoints.

WOC is happy to assist you with any of your GE requirements. Please contact us by phone or email for pricing and availability on any parts and repairs.

What is 3500/62?

It is a process variable monitor designed and developed by Bently Nevada.

How can the Process Variable Monitor be programmed?

The Process Variable Monitor can be programmed to perform current or voltage measurements using the 3500 Rack Configuration Software. This software allows users to customize the alarm setpoints and other parameters to meet their specific application needs.

What types of signal inputs does the Process Variable Monitor accept?

The Process Variable Monitor accepts three different signal input scenarios: +/-10 Volts DC, isolated 4-20 mA, and 4-20 mA with Intrinsically Safe zener barriers.

What is the Triple Modular Redundant (TMR) configuration?

The Triple Modular Redundant (TMR) configuration is a type of configuration used in the 3500 rack-based monitoring system to ensure redundancy and reliability. In this configuration, Process Variable Monitors must be installed adjacent to each other in groups of three. The monitor uses two types of voting in this configuration to ensure accurate operation and to avoid loss of machinery protection due to single-point failures.